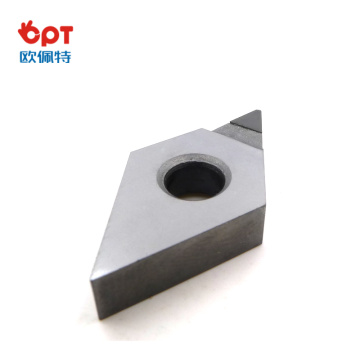

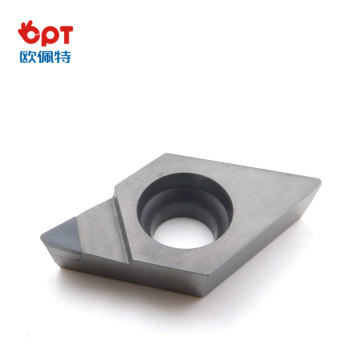

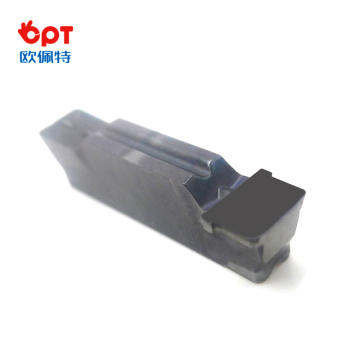

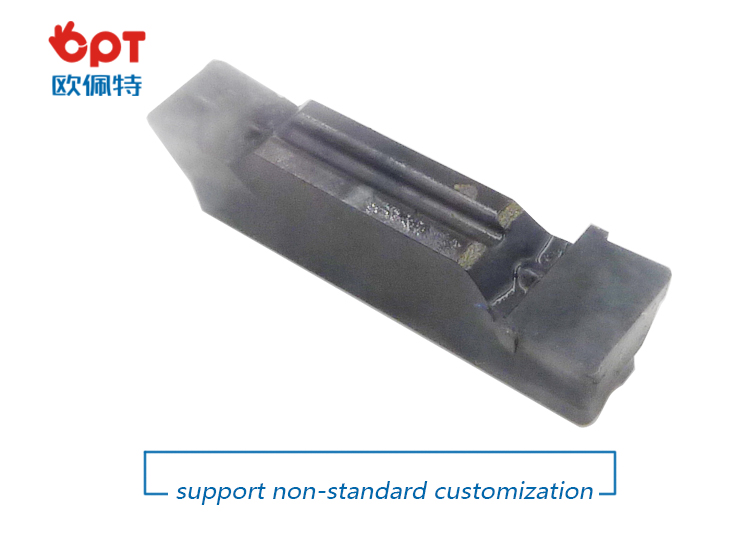

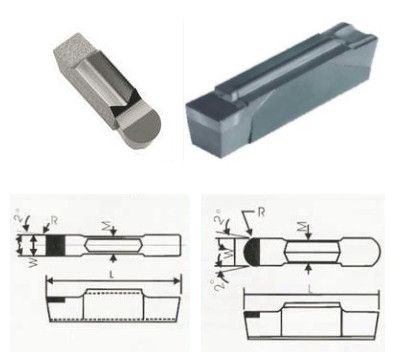

PCD inserts groving inserts

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Port: | Yantian,Shekou,Chiwan |

PCD groving inserts:

PCD tools are mainly used in the following two aspects:

1 Difficult to process non-ferrous metal materials: When machining difficult-to-process non-ferrous metal materials with ordinary tools, defects such as easy tool wear and low processing efficiency are often produced, while PCD tools can exhibit good processing performance. For example, the PCD tool can effectively process the new engine piston material, hypereutectic silicon aluminum alloy (the research on the processing mechanism of this material has made a breakthrough).

2 Processing of difficult-to-machine non-metallic materials: PCD cutters are ideal for processing difficult-to-machine non-metallic materials such as stone, hard carbon, carbon fiber reinforced plastic (CFRP), and artificial boards.

We provide free samples to customer,but buyer should bear freight.

Our company provide good after-sale service and technology support,If any quality problem is proved to be our responsibility, you can return the product in full and give it to you.

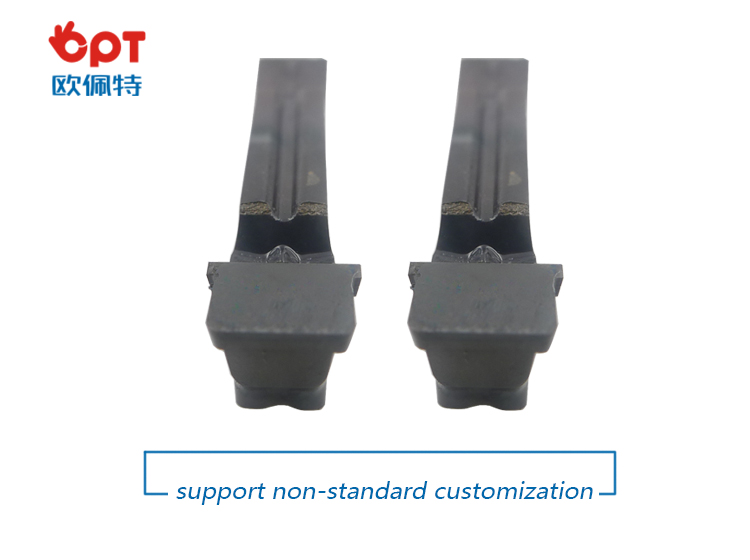

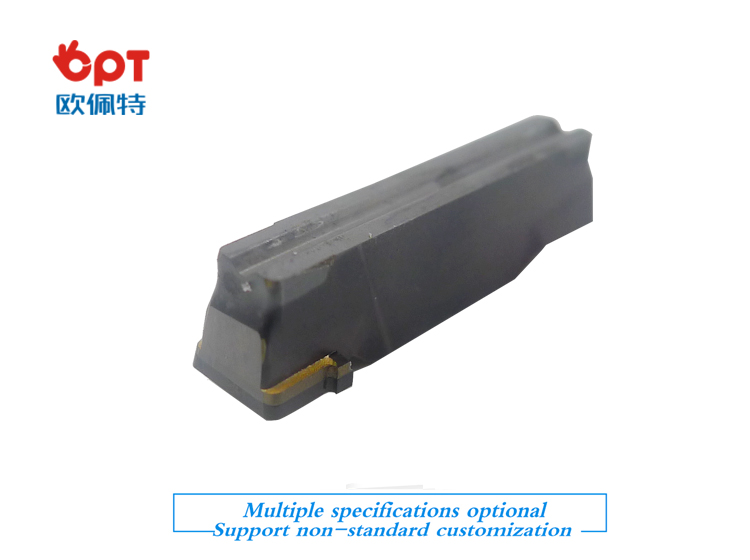

Diamond grooving tools and profile turning tools with extremely high precision for manufactoring pistons. These tools are used mainly for the grooving of piston head rings.

For external grooving, groove turning, profiling and undercutting. Various PCD materials and CBN materials find application to the workpiece material.

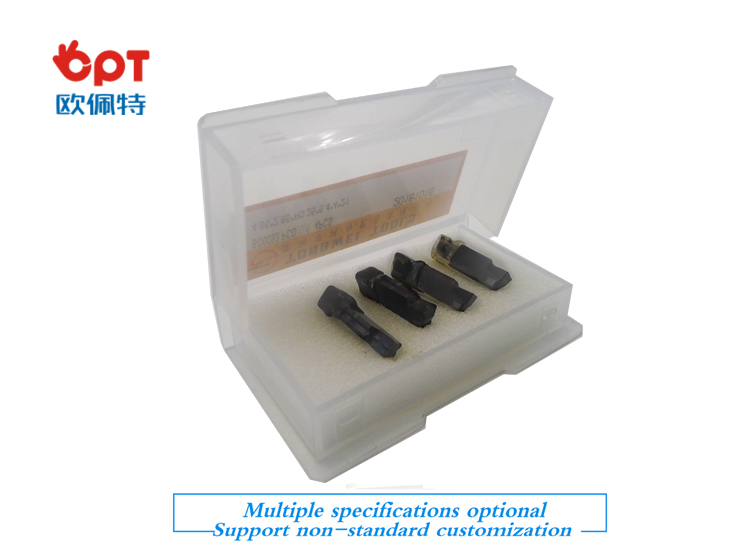

OPT Tool designs and manufactures PCD groove tools that are to your specific width and depth requirements. Our engineers can assist in designing special groove, chamfer and form tools to meet the requirements of your project. Chip control designs are available for groove, profile and groove-turn applications. Tolerances of 2 microns are consistently held on our insert geometries.

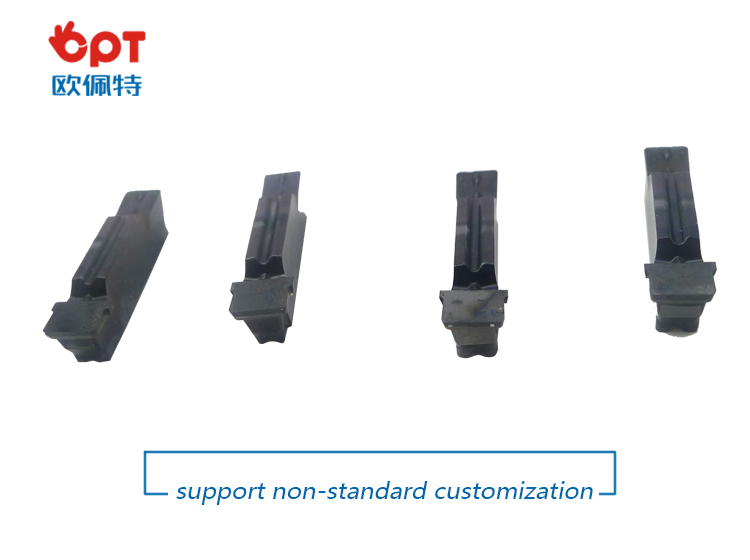

Description

Dimension(mm)

Grade

W

r

l

d

a°

OPT850

OPT005

OPT010

OPT302

KGMN

200-02-L

2

0.2

20

1.7

-

300-02-L

2

0.2

20

2.3

-

400-02-L

4

0.2

20

3.3

-

500-03-L

5

0.3

25

4.1

-

600-03-L

6

0.3

25

5.1

-

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and

Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords