PCD Diamond tipped T-Slot bits

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

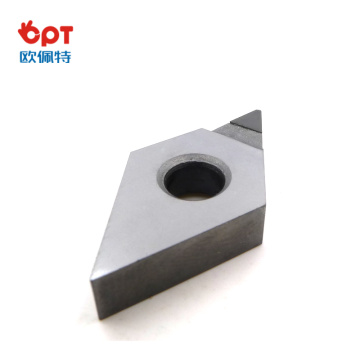

Diamond tipped T-Slot bits

Characteristics of PCD T-Slot bits:

Made of high-toughness materials, it is tough and durable, with high toughness and high shock resistance. It can be used for ultra-deep boring (10D). Each specification has internal water holes, and the chip removal and cooling effect during deep hole processing is good. There are joint holes at both ends of the shank, one end is damaged, and the other end can be used together; economical and practical.

The company can also design and produce a variety of non-standard tools according to customer needs, prompt delivery and reasonable price. Non-standard combination tools produced by the company are widely used

In the industries of automobiles, airplanes, ships and other industries, it not only improves the processing precision for customers, but also greatly improves the production efficiency, and is well received by new and old customers

Advantage :

1. With ultra high hardness and super wear resistance;

2. Stable performance and long tool life;

3.High processing efficiency and low cost;

4.can obtain a higher surface finish;

5.High conductivity and good toughness.

Specifications

1. PCD cutter for stone

2. High quality PCD tipped bit

3. Carving for Circuit board, PVC

4. ISO9001 and BV certification

Features of PCD diamond carving cutter

1. The center sharp knife of the PCD carving cutter features long service life and good adaptability. It is particularly suitable to engrave granite and ceramic. Its maximum engraving depth can reach 1mm.

2. The flat bottom knife is used to engrave characters with smooth edges. The size of the engraving characters ranges from 3cm to 8cm. The knife features fast engraving speed and long service life. Its maximum engraving depth can reach 4mm.

3. The PCD carving cutter can mill the groove at the bottom of the engraving picture. The carving cutter features fast processing speed and high work efficiency. You can choose milling bedplate cutters of different sizes according to the size of the processing surface. The recommended engraving depth of the carving cutter is 2mm.

ABOUT US :

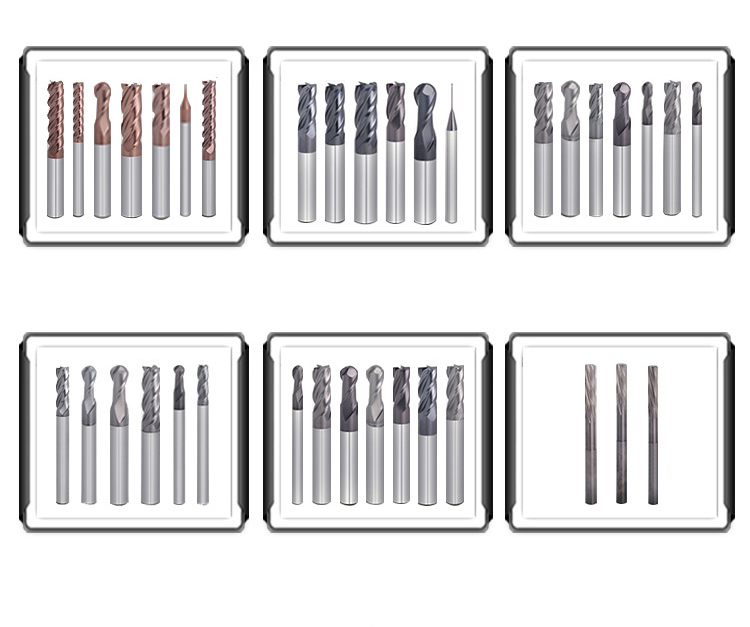

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords