PCD micro combination full twist layout drills

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9000 |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

PCD micro combination full twist layout drills

The thinner PCD layer thickness facilitates EDM of the insert. When the PCD composite sheet and the blade body material are welded, the thickness of the hard alloy layer cannot be too small to avoid delamination due to the difference in stress between the two materials' bonding surfaces.

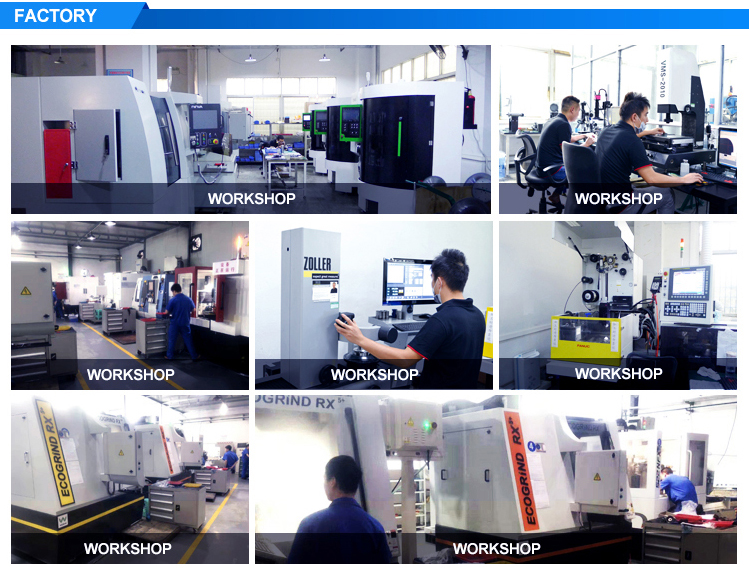

OPT PCD drills use parallel diamond wheels for grinding throughout the process. By welding an incomplete cemented carbide matrix to cemented carbide and steel. We have our own workshop and equipped with state-of-the-art equipment which include EDM machining, CNC machining, Slow wire cutting machine and so on. PCD drills is suitable for processing non-ferrous metals such as copper, zinc and alloys, and non-metal materials such as plastics.

Features:

1. Increased abrasion resistance

2. Extended tool life while drilling

3. Up to twice the speed when drilling

4. Stable performance during tool life

5. High surface finish

Main Products:

1. PCD inserts

2. PCD reamers

3. PCD End mills

4. Woodworking Tools

5. Carbide insrts

6. Carbide End Mills

7. Carbide drills

8. Carbide Taps and so on

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry.

Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords