Carbide britain cutter taps

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000month/pieces |

| Supply Ability: | 10000month / pieces |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

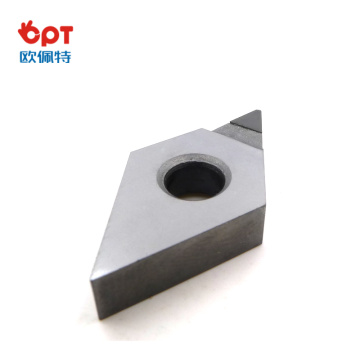

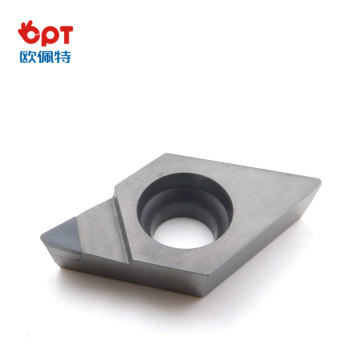

Britain cutter taps

Method and technique for manual tapping with a common tap In the current actual production, many threads can only be manually tapped due to their special shape and position. The small size thread has low strength and small hole diameter, and the tapping thread is easy to break the tap, so it is usually manually tapped. However, the manual tapping has relatively high technical requirements for workers, and the quality is not easy to guarantee, so it is necessary to master the correct operation method.

1) Before tapping the thread, first use the scribing tool to scribe and lay the bottom hole. The bottom hole should be chamfered. The diameter of the chamfer should be slightly larger than the diameter of the thread, so that the tap can be easily cut when starting to cut, and the hole can be prevented. The mouth squeezes out the rim.

2) Workpiece clamping. Use a vise to clamp and mount the workpiece. Generally, the side that needs to be tapped should be placed horizontally. If the shape of the workpiece is not allowed, consider placing the threaded surface in the vertical direction. The workpiece clamp is beneficial for balancing the force during tapping and controlling the tapping speed and ensuring the tapping quality.

Features:

Taps are usually divided into single or groups. The through-hole thread of the small and medium size can be tapped once with a single tap. When processing a blind hole or a large-sized screw hole, a group of taps is commonly used, that is, one screw hole is sequentially processed by using two or more taps. Group taps have equal and unequal diameters

Two designs. The taps of the equal-diameter design have different lengths of the cutting cones only; the taps of the unequal-diameter design have different thread sizes, and only the last one has a complete tooth shape.

Characters and advantages of products:

1 high precision

2 high efficiency

3 all the cutting tools quality meet the ISO international standard.

4 high strength and high hardness, hard-wearing

5 competitive price

6 fast deliv

| Size | Nominal diameter | TPI/1 | Flute | O.A.L | Thread lengh | Shank Dia. | Model No. | |

| M | Z | L1 | L2 | D2 | Uncaoted | caoted | ||

| 1/8 | 3.2 | 40 | 3 | 50 | 16.5 | 3.15 | 4735-032Z | ■ 4735T-032Z |

| 3/16 | 4.8 | 24 | 3 | 58 | 20.5 | 5 | 4735-048X | ■ 4735T-048X |

| 1/4 | 6.4 | 20 | 3 | 66 | 24.5 | 6.3 | 4735-064W | ■ 4735T-064W |

| 5/16 | 7.9 | 18 | 4 | 72 | 22 | 5.6 | 4745-079V | ■ 4745T-079V |

| 3/8 | 9.5 | 16 | 4 | 80 | 24 | 7.1 | 4745-095U | ■ 4745T-095U |

| 7/16 | 11.1 | 14 | 4 | 85 | 25 | 8 | 4745-111T | ■ 4745T-111T |

| 1/2 | 12.7 | 12 | 4 | 89 | 29 | 9 | 4745-127R | ■ 4745T-127R |

| 9/16 | 14.3 | 12 | 4 | 95 | 30 | 11.2 | 4746-143R | ■ 4746T-143R |

| 5/8 | 15.9 | 11 | 4 | 102 | 32 | 12.5 | 4745-159Q | ■ 4745T-159Q |

| 3/4 | 19.1 | 10 | 4 | 112 | 37 | 14 | 4745-191P | ■ 4745T-191P |

| 7/8 | 22.2 | 9 | 4 | 118 | 38 | 16 | 4745-2220 | ■ 4745T-222O |

| 1" | 25.4 | 8 | 4 | 130 | 45 | 18 | 4745-254N | ■ 4745T-254N |

PRODUCT DETAIL:

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords