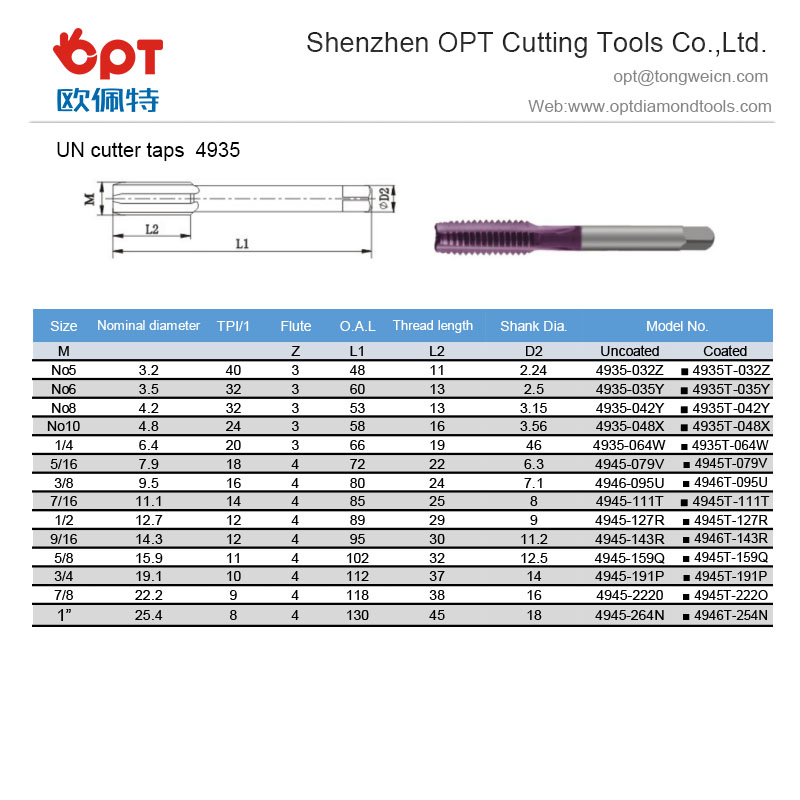

Carbide UN cutter taps

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000month/pieces |

| Supply Ability: | 10000month / pieces |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

Carbide UN cutter taps

Tap It is a tool for machining internal threads with grooves in the axial direction. Also called screw attack. According to its shape, the tap is divided into a straight groove tap, a spiral groove tap and a screw tip tap. The straight groove tap is easy to process, the accuracy is slightly lower, and the output is larger. Generally used for threading of ordinary lathes, drill presses and tapping machines, the cutting speed is slow. Spiral groove taps are mostly used for drilling blind holes in CNC machining centers. The machining speed is fast, the precision is high, the chip removal is good, and the centering is good. The front of the threaded tap has a groove for the processing of the through hole. The taps provided by today's tool factories are mostly coated taps, which have greatly improved the service life and cutting performance of uncoated taps. Uses: For the processing of nuts or other internal thread on the machine (ie tapping). Machine taps usually refer to high-speed steel grinding taps, suitable for tapping on machine tools; hand taps are carbon tool steel or Alloy tool steel rolling (or incisor) tap for manual tapping.

Features:

carbide Taps are usually divided into single or groups. The through-hole thread of the small and medium size can be tapped once with a single tap. When processing a blind hole or a large-sized screw hole, a group of taps is commonly used, that is, one screw hole is sequentially processed by using two or more taps. Group taps have equal and unequal diameters

Two designs. The carbide taps of the equal-diameter design have different lengths of the cutting cones only; the carbide taps of the unequal-diameter design have different thread sizes, and only the last one has a complete tooth shape.

Spiral-Pointed taps, or Machine Taps, were originated to solve the problem of tap breakage in through hole tapping. The Machine Tap shoots chips ahead of the cutting action, thus reducing loading and clogging in the flutes. They are recommended for use in through or blind holes which allow for chip accumulation in the bottom of the hole. Ideal for threading a wide variety of ductile materials, copper and copper alloys, brass and non-metallics.

Characters and advantages of products:

1 high precision

2 high efficiency

3 all the cutting tools quality meet the ISO international standard.

4 high strength and high hardness, hard-wearing

5 competitive price

6 fast deliv

PRODUCT DETAIL:

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords