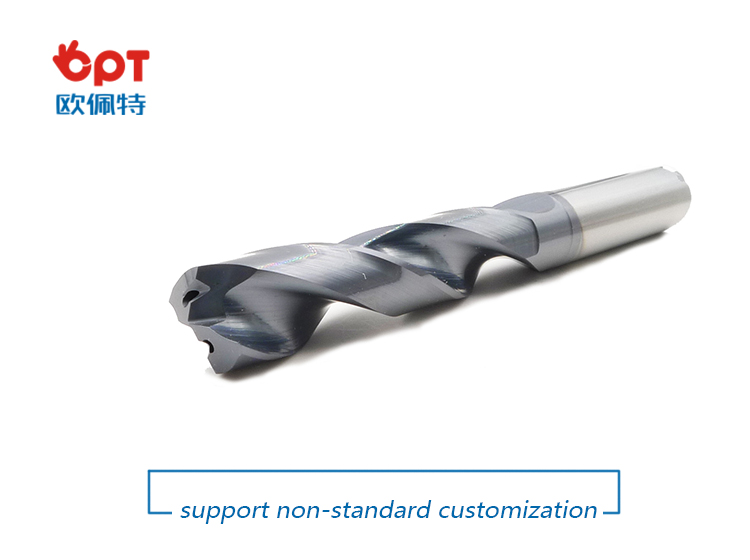

Solid carbide high feed rate twist drills

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000 pcs/month |

| Supply Ability: | 5000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9000 |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Hongkong |

Solid carbide high feed rate twist drills

Drill bit geometry has several characteristics:

1. The spiral (or rate of twist) in the drill bit controls the rate of chip removal.

2. The point angle, or the angle formed at the tip of the bit, is determined by the material the bit will be operating in.

3. The lip angle determines the amount of support provided to the cutting edge.

Application area:

Drilling can be done by almost any machining tool that is capable of cutting, including drilling lathes, milling machines and drill presses.

Advantages:

1.The unique drill point makes cast iron more light and steady.

2. Blade passivation ,impact resistance , anti collapse ,and life increase.

3. The chip cutting trough has large space and fast chip removal , which is suitable for high-passed and large feed cutting.

Product Show:

Releated Products:

PCD Inserts>>

PCD Inserts>>

Carbide Taps>>

Carbide Taps>>

Material:

Tungsten Carbide

Packaging:

Be

packed with plastic case or box.

Quality control:

We have dedicated team of quality control and art equipment to keep good and stable performance for our products.

OEM/ODM Service:

Customization cutting tools is an easy process when partnering with OPT. From drawing to tooling completion takes no longer than 4 weeks. With a sample profile, a CAD file or a dimensioned sketch, we design precision profile tooling with safety, accuracy, exceptional performance and our customer`s complete satisfaction in mind.

Our Service:

- sample is available for testing before ordering

- Customer oriented

- After sale replace service

- Full stock available for urgent demands

About us:

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Reamers, PCD Forming tools, PCD Woodworking Tools, Carbide Taps, Carbide Drills and many more.

If you encounter problems such as high-speed, high precision requirements, low tool life and so on in the processing, you may contact us to recommend appropriate design for you, we can provide customization per your drawing.

Related Keywords