Internal cold fixed handle twist drill 1100A

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Shekou, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Shekou,Yantian |

Internal cold fixed handle twist drill 1100A

The solid carbide drill bits on the market are generally monolithic drill bits made of tungsten steel. Although the materials are the same, due to the processing technology, the quality of each brand's products is very different. Imported and domestic alloy drill bits also vary widely.Carbide tipped tools are more efficient and cost effective compared to high speed tools because they retain their cutting edge hardness at high machining temperatures which are generated by high cutting speeds.

Drilling is the process most commonly associated with producing machined holes, because it is simple, quick and economical.

After coating, the alloy drill bit can process low alloy steel and high strength steel. High-hard steel can reach 54HRC.

Characters and advantages of products:

1 high precision

2 high efficiency

3 all the cutting tools quality meet the ISO international standard.

4 high strength and high hardness, hard-wearing

5 competitive price

6 fast delivery

product detail:

F.D

Shank dia

O.A.L

Flute length

Shank length

Length of cut section

Module No.

D1

D2

L1

L2

L3

L4

Uncoated

Coated

3

6

66

28

36

23

1100A-030

■ 1100A-030T

4

6

66

28

36

23

1100A-035

■ 1100A-035T

4

6

74

36

36

29

1100A-040

■ 1100A-040T

5

6

74

36

36

29

1100A-046

■ 1100A-045T

5

6

82

44

36

35

1100A-050

■ 1100A-050T

6

6

82

44

36

35

1100A-055

■ 1100A-055T

6

6

82

44

36

35

1100A-060

■ 1100A-060T

7

8

91

63

36

43

1100A-065

■ 1100A-065T

7

8

91

53

36

43

1100A-070

■ 1100A-070T

8

8

91

53

36

43

1100A-075

■ 1100A-075T

8

8

91

53

36

43

1100A-080

■ 1100A-080T

9

10

103

61

40

49

1100A-085

■ 1100A-085T

9

10

103

61

40

49

1100A-090

■ 1100A-090T

10

10

103

61

40

49

1100A-096

■ 1100A-096T

10

10

103

61

40

49

1100A-100

■ 1100A-100T

11

12

118

71

45

56

1100A-110

■ 1100A-110T

12

12

118

71

45

56

1100A-120

■ 1100A-120T

14

14

124

77

45

60

1100A-140

■ 1100A-140T

15

16

133

83

46

63

1100A-150

■ 1100A-150T

16

16

133

83

48

63

1100A-160

■ 1100A-160T

18

18

143

93

48

71

1100A-180

■ 1100A-180T

20

20

153

101

50

77

1100A-200

■ 1100A-200T

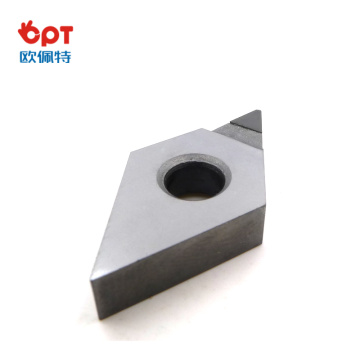

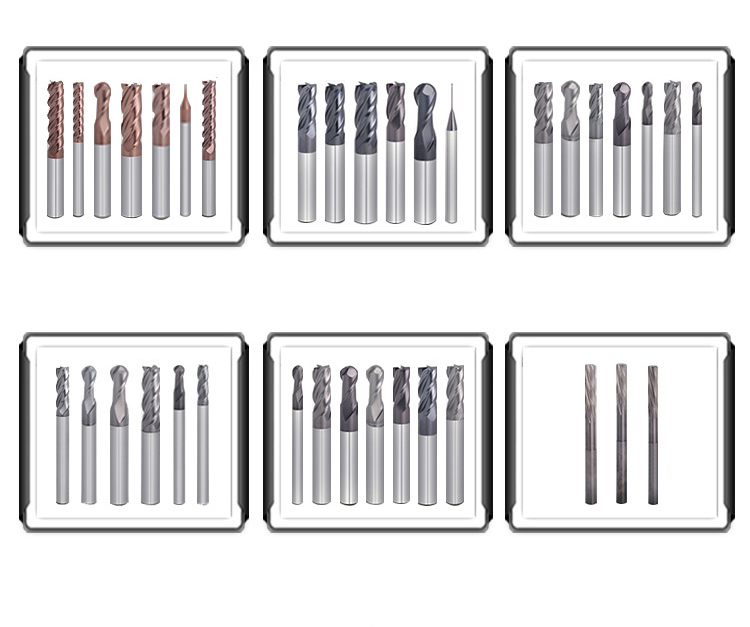

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and

Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing

with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in

the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords