Coolant carbide straight drill 1203A

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Shekou, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Shekou,Yantian |

Coolant carbide straight drill 1203A

Coolant Fed Twist Drills are used in drilling machines which feed coolant directly to the cutting edge during operation, reducing temperatures and flushing chips out of the hole for faster work, longer tool life and reduced downtime. Taper shank models have dual coolant entry in the tang end and the side of the taper, while straight shank models are used in appropriate coolant-fed toolholders. Large holes at the point end improve coolant flow to the workpiece for decreased friction and better chip removal. Suitable for a variety of stainless steels, cast iron, and other ferrous and non-ferrous metals and alloys. For best results when drilling under 3/8" diameter, use a drill bushing or pilot hole of the same dimension.

Features and Benefits

OPT Deep hole drills four-margin long-length drills with through coolant.

Application-specific SC drill for deep-hole applications without pilot drill in steel, cast iron, and stainless steel materials.

12 x D long-length drills closing the gap between 8 x D (B256_SE) and 15 x D (B271_HP) drills.

Standard A-shank according to DIN 6535 HA (round cylindrical with 2mm steps).

OPT Deep hole drills is a multilayer, TiAlN-based coating with high hot hardness.

The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

Characters and advantages of products:

1 high precision

2 high efficiency

3 all the cutting tools quality meet the ISO international standard.

4 high strength and high hardness, hard-wearing

5 competitive price

6 fast deliv

| F.D | Shank dia | O.A.L | Flute length | Model NO. | ||

| Length of cut section | ||||||

| D1 | D2 | L1 | L2 | L3 | Uncoated | Coated |

| 5 | 5 | 62 | 26 | 19 | 1203A-050 | ■ 1203A-050T |

| 5.5 | 5.5 | 66 | 28 | 20 | 1203A-055 | ■ 1203A-066T |

| 6 | 6 | 66 | 28 | 19 | 1203A-060 | ■ 1203A-060T |

| 6.5 | 6.5 | 70 | 31 | 21 | 1203A-065 | ■ 1203A-065T |

| 7 | 7 | 74 | 34 | 24 | 1203A-070 | ■ 1203A-070T |

| 7.5 | 7.5 | 74 | 34 | 23 | 1203A-075 | ■ 1203A-075T |

| 8 | 8 | 79 | 37 | 25 | 1203A-080 | ■ 1203A-080T |

| 8.5 | 8.5 | 79 | 37 | 24 | 1203A-085 | ■ 1203A-085T |

| 9 | 9 | 84 | 40 | 27 | 1203A-090 | ■ 1203A-090T |

| 9.5 | 9.5 | 84 | 40 | 26 | 1203A-096 | ■ 1203A-096T |

| 10 | 10 | 89 | 43 | 28 | 1203A-100 | ■ 1203A-100T |

| 11 | 11 | 95 | 47 | 31 | 1203A-110 | ■ 1203A-110T |

| 12 | 12 | 102 | 51 | 33 | 1203A-120 | ■ 1203A-120T |

| 14 | 14 | 107 | 54 | 33 | 1203A-140 | ■ 1203A-140T |

| 15 | 15 | 111 | 56 | 34 | 1203A-150 | ■ 1203A-150T |

| 16 | 16 | 115 | 58 | 34 | 1203A-160 | ■ 1203A-160T |

| 18 | 18 | 123 | 62 | 35 | 1203A-180 | ■ 1203A-180T |

| 20 | 20 | 131 | 66 | 36 | 1203A-200 | ■ 1203A-200T |

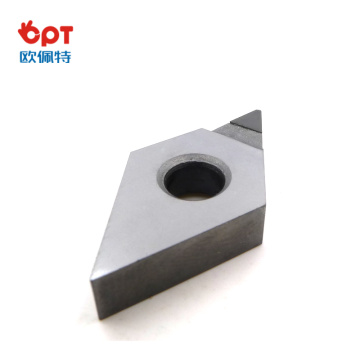

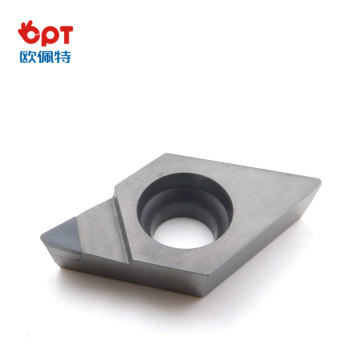

product detail:

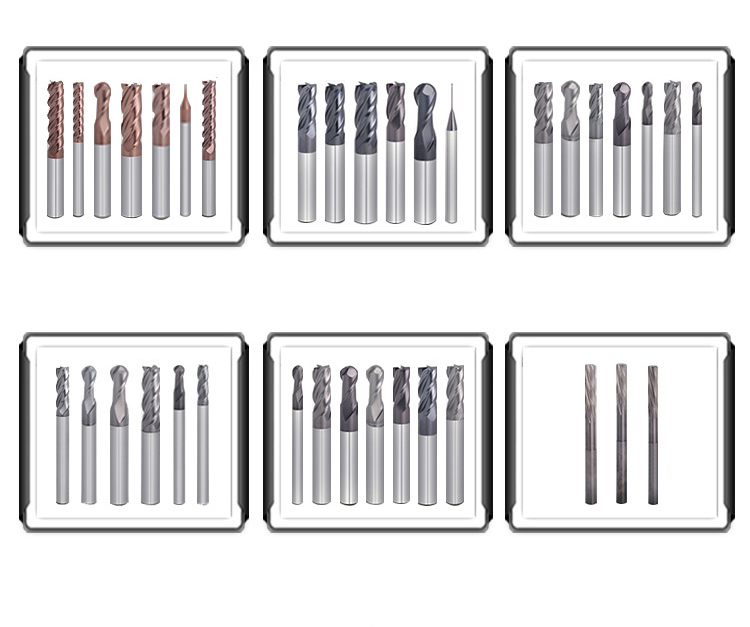

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and

Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing

with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in

the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords