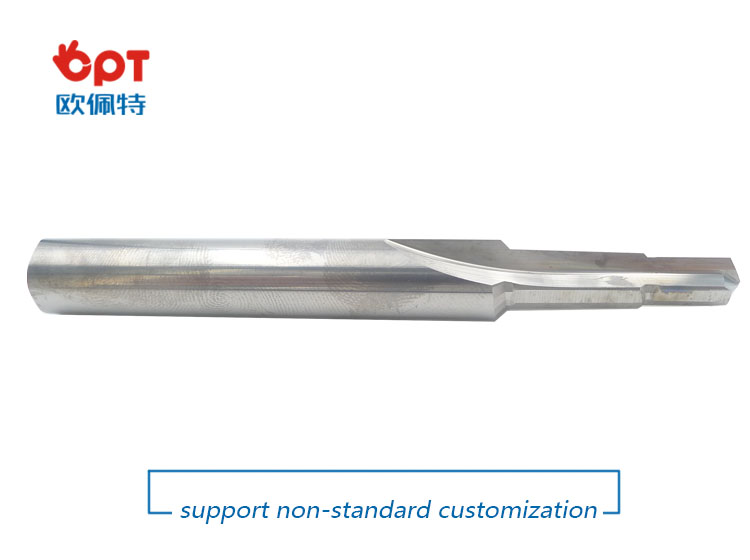

Tungsten carbide spiral flute step drill bit set

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

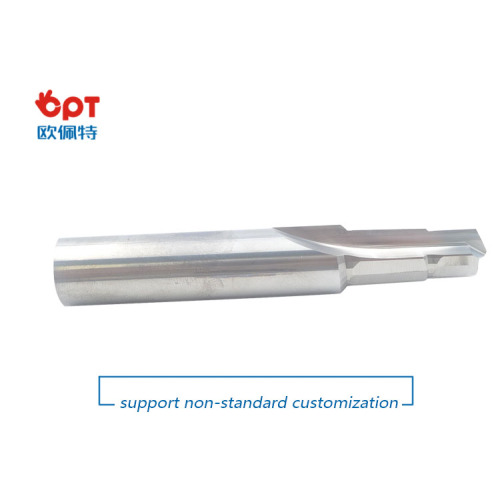

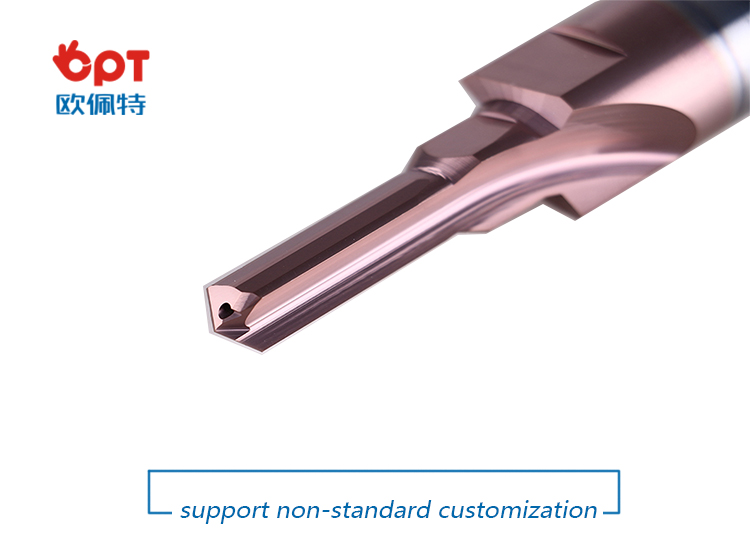

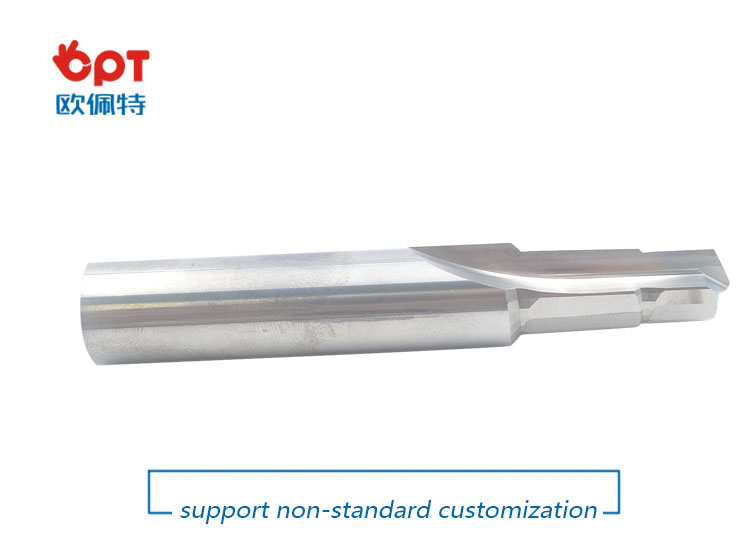

Tungsten carbide spiral flute step drill bit set

Carbide step drills are also called step drills or pagoda drills. They are mainly used for drilling thin steel sheets within 3mm. One drill bit can be used instead of multiple drills. Different diameter holes can be machined according to needs, and large holes can be realized. One-time processing is completed, no need to change the drill bit and position the positioning hole.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remains basically unchanged even at a temperature of 500 ° C. At 1000 ° C, there is still a high hardness. In the aspect of cast iron processing, our reamer can process the smoothness of the hole to less than 0.4.

Scope of application: The reamer has multiple cutter machining characteristics, which are used to ream the drilled (or reamed) hole on the workpiece, mainly to improve the machining accuracy of the hole and reduce the surface roughness. In the finishing of the hole, the semi-finished tool has a small machining allowance. Because the reamer has the blunt radius of the cutting edge, it has a wiper blade, and the flank has a 0.03~0.05mm edge. Therefore, the pressing action is large, so the reaming process is actually the result of both cutting and squeezing.

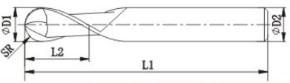

|

F.D |

Shank Dia. |

O.A.L |

Flute length |

Length of cut section |

Modle No. |

|

|

D1 |

D2 |

L1 |

L2 |

L3 |

Uncoated |

Coated |

|

3.3 |

6 |

66 |

28 |

11.4 |

ZX13A-033 |

ZX13A-033T |

|

4.2 |

6 |

66 |

28 |

13.6 |

ZX13A-042 |

ZX13A-042T |

|

5.0 |

8 |

79 |

41 |

16.5 |

ZX13A-050 |

ZX13A-050T |

|

6.8 |

10 |

89 |

47 |

21.0 |

ZX13A-068 |

ZX13A-068T |

|

8.5 |

12 |

100 |

55 |

25.5 |

ZX13A-085 |

ZX13A-085T |

|

10.2 |

14 |

107 |

60 |

30.0 |

ZX13A-102 |

ZX13A-102T |

|

12.0 |

16 |

115 |

65 |

34.5 |

ZX13A-120 |

ZX13A-120T |

|

14.0 |

18 |

123 |

73 |

38.5 |

ZX13A-140 |

■ ZX13A-140T |

ABOUT US :

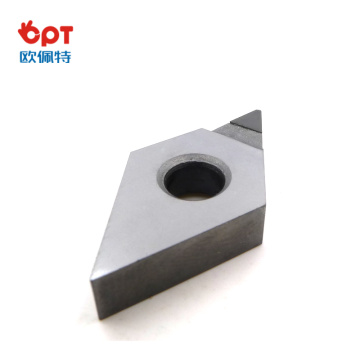

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords