OSP Single Side PCB

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Product Description

Product Description

Keywords:OSP Single Side PCB, Single Layer PCB OEM, Epoxy Board FR4 PCB Single, PCB Board Single Side

Common Type of PCB Surface Finish

HASL, lead free HASL, ENIG, Flash gold, Thick gold, Selective gold plating, OSP, Selective OSP /HASL, Immersion Tin, Immersion Silver, Immersion Gold.

In PCB production process, we provide all kinds of surface treatment processes, including single-sided PCB, double-sided PCB, multi-layer PCB, etc. OSP is different from other surface treatment processes in that its function is to act as a barrier between copper and air; in short, OSP is to grow an organic skin film on the clean bare copper surface by chemical method. The film has oxidation resistance, heat shock resistance, and moisture resistance to protect the copper surface from further rusting (oxidation or vulcanization, etc.) in the normal environment; at the same time, it must be easily removed by the flux in the subsequent high-temperature welding, so as to facilitate welding.

The organic coating process is simple and low cost, which makes it widely used in the industry. The early organic coating molecules were imidazole and benzotriazole, and the latest ones were benzimidazole. In order to ensure that multiple reflow welding can be carried out, only one layer of organic coating on the copper surface is not allowed, there must be many layers, which is why the chemical tank usually needs to add copper liquid. After coating the first layer, the coating adsorbs copper; then the organic coating molecules of the second layer combine with copper until the organic coating molecules of 20 or even 100 times aggregate on the copper surface.

The general process is degreasing > micro etching > pickling > pure water cleaning > organic coating > cleaning. The process control shows that the treatment process is relatively easy compared with other processes.

PCB Manufacturing Base Material

CEM1, CEM3, Middle-Tg FR4, High-Tg FR4, Halogen free, BT / Rogers / PTFE, Aluminum base material

Special Technology: Impendence Control, Differencial PCB printed circuit board, Peelabemask PCB , High Density PCB HDI, Heavy copper PCB ,Metal Core circuit boards ,Copper Clad PCB printed circuit board, Blind & Buried Vias, Laser Drilled Vias, Burn-in Boards,Flex Boards, Rigid Flex PCB printed circuit board , Edge half plated thru hole Circuit boards, Selective Plating Hard Gold, Special Thin or Special Thick PCB board, PCB with Resin Plugged Hole.

Why choose us?

With Nearly 10 years of PCB manufacturing experience, JingHongYi PCB (HK) Co., Limited is rapidly becoming the logical choice for PCB manufacturers in Shenzhen, China. We're proud to manufacture high-quality products. We can handle production orders on 1 layers all the up to 24 layers(single sided PCB, double sided PCB, multilayer PCB, rigid PCB, flexible PCB, high-frequency PCB, etc.). and we have quick turn , Small volume and large volume service type PCB assembly services without MOQ.

No MOQ, low cost for small quantity prototype. We penalize prototype circuit boards on a big panel which will share set-up costs with other customers, which could save a lot of PCB tooling cost for small quantity PCB prototype. PCB manufacturing on spec. We have professional engineering in each production process from evaluating cost, checking and assessing Gerber requirement, making MI to production and final inspection to guarantee circuit board quality. Meeting your printed circuit board needs from PCB prototyping to mid-volume production ISO/TS certified PCB manufacturing factory. Deliver on time. We keep higher than 99% on-time-delivery rate Combined service to arrange your PCB to you by DDU TO DOOR shipment with competitive shipping cost. You don't need to arrange anything after confirming the order just wait for your PCB deliver to your hand. Offer free DRC for DFM to our customers. Decades of experience in supporting manufacturing PCB requirements from a wide range of industries.

Minimum Order Quantity: 1pcs

Price: The price will change with different process and quantity

Packaging Details: box

Delivery Time: quick turn and normal type

Payment Terms: TT, LC, and others base on negotiation

Supply Ability: 1, 000, 000PCS/week

What is Single Sided PCB

There are many similarities and differences between single sided PCB and double sided PCB, and we will also explain them here.

Single Sided PCB Manufacturing

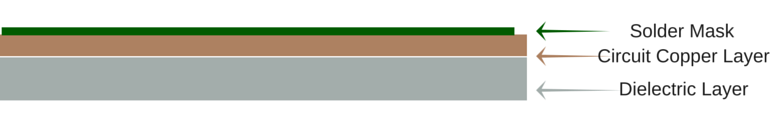

One thin layer of thermally conductive but electrically insulating dielectric is laminated with copper. Soldermask is usually applied on top of the copper.

JHY PCB produces prototype, midrange and high volume Single Sided circuit boards, with a copper thickness from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C. Single sided boards are available with surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Tin, and Gold plating along with both leaded or lead-free Hot Air Solder Level (HASL).

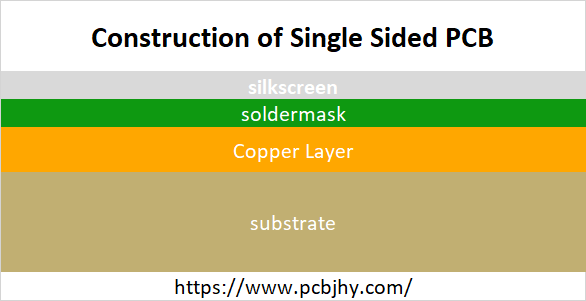

Construction of Single Sided PCB

Above substrate, there lies a copper layer which provides conducting path for various components on the board. The copper thickness is different for different boards depending on your needs and requirements and is defined in ounces per square foot.

On the top of copper foil, there exists a solder mask layer. This layer is mainly used for protection and makes the copper foil insulating which helps in avoiding the conduction in case direct contact happens with some conducting material.

On the top of all layers, there exists a silkscreen layer that is mainly used for adding symbols and characters on the board so a common person can anticipate the clear understanding of the board.

Advantages of Single Layer PCB

- Ideal for simple low-density designs

- Lower cost, especially for high volume orders

- Lower probability of manufacturing issues

- Popular, common, and easily understood by most PCB manufacturers

Application of Single Sided PCB

Aluminum PCB, LED PCB used in LED lighting industry are basically Single Sided PCB.

ALTHOUGH SINGLE SIDED PCBS ARE RELATIVELY SIMPLE, THEY CAN STILL BE USED IN VERY COMPLEX DEVICES:

- Power supplies

- Relays (automotive and industrial)

- Timing circuits

- Sensor products

- LED lighting

- Radio and stereo equipment

- Packaging equipment

- Surveillance

- Calculators

- Printers

- Coffee makers

- Vending machines

- Solid state drives

- Camera systems

Related Keywords

Related Keywords