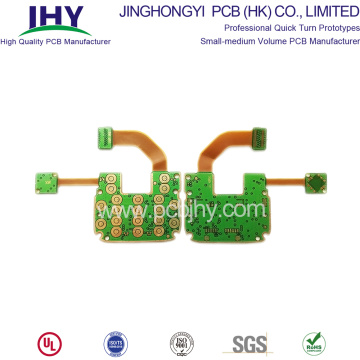

4 Layer Rigid-flexible PCB Blind Hole Plate

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Product parameters

Application: Robot

Type: Four Layer Rigid-flexible PCB

Specification and size: 90.1 * 35.1mm

Thickness of Flexible PCB: 0.13MM ± 0.05mm, FPC + 0.2mm

Thickness of Rigid PCB: 1.6mm ± 0.1mm

Surface treatment: Immersion Gold

Process requirements: white type, blind hole plate

What is rational is actual and what is actual is rational - Georg Wilhelm Friedrich Hegel.

PCB is widely used in our household appliances, industrial production machinery and equipment. However, in general, PCB refers to rigid PCB. Although rigid PCB is the most widely used, but with different application scenarios and functional requirements, rigid-flexible Printed Circuit Board also emerged.

Rigid-flexible PCB has been widely used and developed, which is inseparable from its superior performance.

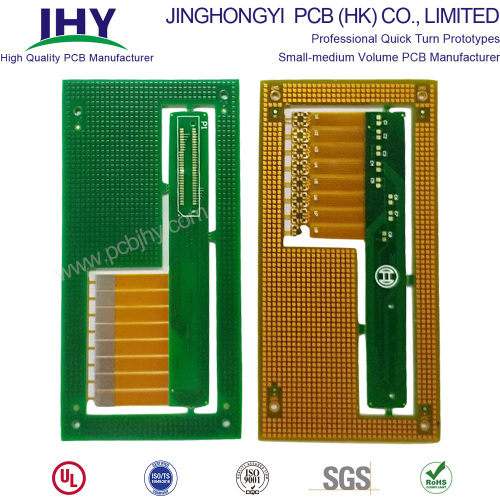

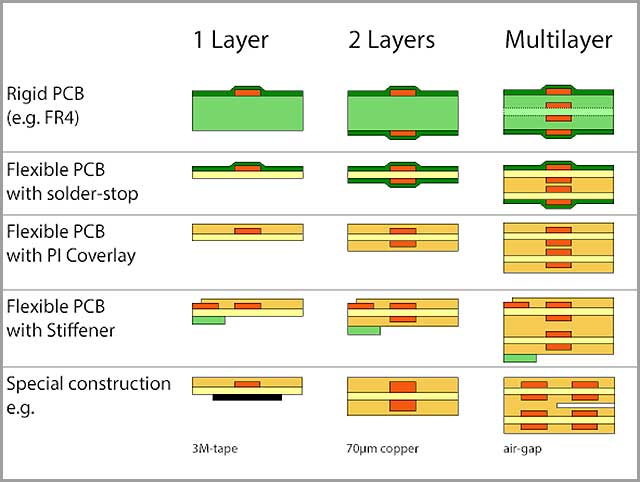

With the development of PCB design and production technology, there have been Double-sided rigid-flexible PCB, multi-layer rigid-flex PCB(3 Layer, 4 Layer, 5 Layer, 6 Layer, 8 Layer, 10 Layer, 12 Layer, 14 Layer), etc.

What's "Rigid-Flex PCB"?

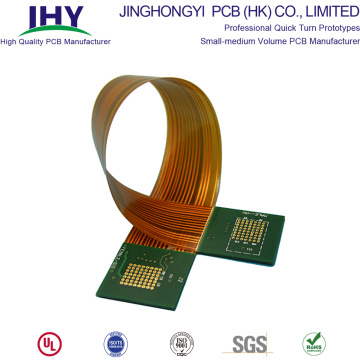

Rigid-Flex circuit is made from a combination of a PI flex material sandwiched between FR4 epoxy or Polyimide rigid layers.

Rigid-Flex circuit boards are composed of a combination of rigid and flexible circuit boards that are permanently connected to one another.

Drilling and plating are processed throughout the sandwiched areas.

Flex-Rigid PCB is a good solution for dynamic application. The whole cost can be profitable and increase the reliability of the device.

Use of Rigid-Flex circuit boards can reduce the total cost of the final product.

Depending on the application, the complete Rigid-Flex circuit board may be manufactured either symmetrically with inward flexible layers, or asymmetrically with outward flexible layers

What makes Rigid-Flex Circuits different from Flex?

In a Rigid-Flex PCB, drilling and plating are processed through Rigid-Flex sandwiched areas.

In a flex PCB with rigid stiffener, no plating through rigid part.

Rigid-Flex is a complex assembly of Rigid parts and Flex parts. Rigid Part can be designed as a HDI product.

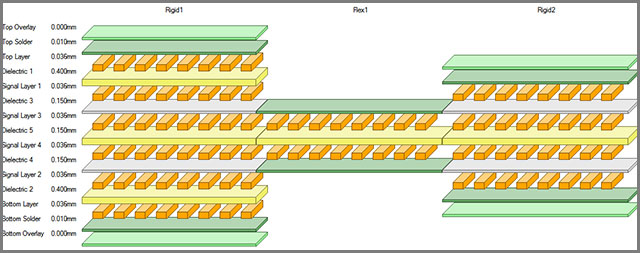

Multilayer Rigid-Flex Circuits Structure

Two or more conductive layers with either flexible or rigid insulation material as insulators between each one, outer layers may have covers or exposed pads.

Rigid-Flex has conductors on the rigid layers, which differentiates it from multilayers circuits with stiffeners. Plated through-holes extend through both rigid and flexible layers (with the exception of blind and buried vias).

Access holes or exposed pads without covers may be on either one or both sides; vias or interconnects can be fully covered for maximum insulation.

Stiffeners are optional.

Rigid-flexible PCB Instant Quote with fast delivery

Request quotes for Rigid-flexible printed circuit board prototypes

Rigid-flex printed circuit boards are PCB combining rigid and flexible board technologies.

A Rigid-flex PCB design improves the reliability of applications by reducing the amount of interconnect points. The less interconnection you have on a design, the stronger your circuit board is, ultimately lowering the final costs of your device or application.

JingHongYi PCB offers the best quality of single-sided, double-sided, or multi-layered Rigid-flex PCBs.

Why Rigid-flex PCB is widely used?

Due to the huge advantages of rigid-flexible PCB, it is widely used in the following products and industries:

- Space requirements can be minimized by applying 3D

- By removing the need for connectors and cables between the individual rigid parts the board size and overall system weight can be reduced.

- By maximizing space, there is often a lower count in parts.

- Less solder joints assure higher connection reliability.

- Handling during assembly is easier in comparison with flexible boards.

- Simplified PCB assembly processes.

- Integrated ZIF contacts provide simple modular interfaces to the system environment.

- Test conditions are simplified. A complete test prior to installation becomes possible.

- Logistical and assembly costs are significantly reduced with Rigid-Flex boards.

- It is possible to increase the complexity of mechanical designs, which also improves the degree of freedom for optimized housing solutions.

Rigid Flex PCB Design

Different applications determine the design idea of rigid-flexible PCB.

New product designs coupled with improved flex circuit technologies have introduced new design rules for rigid-flex PCBs.

When you design rigid-flex PCBs, think in terms of electromechanical factors that affect both the flex circuit and the rigid board.

Before we move onto the proper design of such a PCB, you must also keep certain factors in mind. Technology is always changing and evolving as the years go by; this means that people come up with new designs and methods of creating a Rigid Flex PCB are and will always be different, so there is no absolute way of making a rigid Flex PCB.

Moreover, depending on the application of the rigid flex and its purpose, the design and layout can be very different from the standard design, so keep in mind that the purpose of the PCB can significantly affect the design of the PCB.

The thickness of a Rigid Flex PCB is very subjective, as depending on the purpose of the build the difference can be minor or incredibly significant. The average board thickness for a rigid Flex PCB can be somewhere between 0.2mm and 0.4mm. 0.2mm is the average thickness of a single layer PCB circuit, and 0.4mm is the average thickness of a PCB with nearly 4 layers.

Only when many factors are considered comprehensively to create a Rigid Flex PCB that is both durable and flexible. All of these methods combine to make an effective and efficient circuit board.

Rigid Flex PCB's Technology and manufacturing Process

The technology that most manufacturers use on a PCB differs depending on the manufacturer, type of PCB, and the efficiency of the PCB. The efficiency of the PCB is one of the unique attributes about a rigid flex`s PCB, as depending on the task of the PCB the technology that a designer uses can differ significantly.

The stack up is the process of placing the layers for the rigid flex printed circuit board. Depending on the Rigid-flex circuit board the stack up can be of one, two, or four layer(s), and layers increase by the object`s application as well as its uses.

Factors affecting the cost of rigid-flexible PCB

Rigid Flex PCB Cost, an eternal word.

The cost of a rigid Flex PCB is very different depending on the type of rigid-flex that you get and where you get it from. A rigid-flex PCB can have somewhere between one to four layers of different materials to make up the PCB.

The prices of a Rigid Flex PCB vary greatly depending on the type of PCB that you want, and the layers that it will contain. It means that depending on the type of PCB that you require, the price will increase or decrease.

Another factor the makes up for the cost of the PCB is the developer or manufacturer. Depending on the manufacturer, the price can be reasonable or absurd. However, this high price is justified by the amazing quality of the product as well as the immense attention to detail that the more expensive manufacturer will give to your product.

Related Keywords