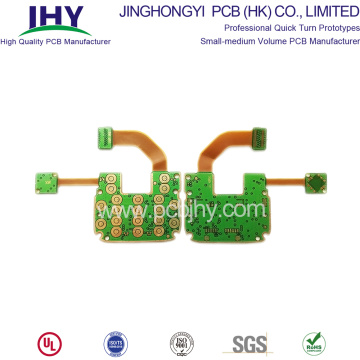

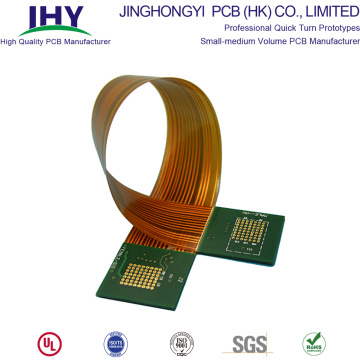

High Precision Manufacturing Rigid Flexible PCB

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

What is a Rigid Flex PCB?

Rigid Flex circuit boards are composed of a combination of rigid and flexible printed circuit boards that are connected to one another by lamination. so most of the rigid flex pcb are made of multiple layers of flexible circuit substrates attached to one or more layer rigid boards internally or externally, depending upon your design for the specified application.

At present rigid flex pcb is applied in more and more application, as it can offers optimum solutions for limited installation space conditions. and also rigid flex pcb provides the possibility of secure and high electrical connection performance of the device components with the assurance of contact stability, as well as a reduction in plug and connector components.

Rigid flex circuits have been used in the military and aerospace industries for more than 20 years. In most rigid flex circuit boards, the circuitry consists of multiple flexible circuit inner layers selectively attached together using an epoxy pre-preg bonding film, similar to a multilayer flexible circuit. However, a multilayer rigid flex circuit incorporates a board externally, internally or both as needed to accomplish the design.

Rigid flex circuits combine the best of both rigid boards and flexible circuits integrated together into one circuit. The two-in-one circuit is interconnected through plated thru holes. Rigid flex circuits provide higher component density and better quality control. Designs are rigid where extra support is needed and flexible around corners and areas requiring extra space.

While the design options are endless when combining rigid boards with flexible circuits, we have provided you with rigid flex combinations that are most commonly utilized.

Technology at Your Fingertips

Our printed circuit board manufacturers specialize in different areas of PCB manufacturing, giving us the unique ability to not only build your boards economically, but to also maintain the highest quality standards. Because of our high order volumes we have negotiated pricing much lower and we believe you cannot find a better value anywhere else.

What we can do?

1.PCB production service. Available on CEM-1,CEM-3, FR-4, TG150-180, Aluminum, Rigid, FPC

2. PCB and PCBA manufacturing and copy service (PCB and PCBA reverse engineering service)

3. PCB assembly service. Available on SMT, BGA, DIP.

4. End products assemble. Available on Final Functional testing and final package

5. Electronic Components purchasing service

6. PCB and PCBA design service

The Boards we can make are High Frequency PCB, PCB Assembly one-stop service, Flexible PCB, Rigid-Flex PCB, Prototype PCB, LED PCB, Quick Turn PCB, Multilayer PCB, High Tg PCB, etc.

Quick Details:

Place of Origin:

Brand Name:

JingHongYi PCB

Base Material:

FR-4

Copper Thickness:

0.5-1 Oz, 1oz~4oz

Board Thickness:

1.6mm, 1.6mm-3.2mm

Min. Hole Size:

0.2mm/0.3mm

Min. Line Width:

0.1mm/4mil, 0.1mm/4mil

Min. Line Spacing:

0.1mm (4mil)

Surface Finishing:

OSP, Immersion gold, HASL, Gold finger, Hard plating

Product name:

Printed Circuit Board

red,yellow,black,green,white

Material:

FR-4,Halogen free,High TG,Cem-3,PTFE,Aluminum BT,Roger etc.

Application:

Electronics Device

Testing:

X-ray, 3D Paste Thickness, ICT, AOI

0.1mm/4mil

Color:

White, Black, Yellow, Red, Blue, Purple etc.

Standard:

RoHS, CE, SGS

V-Cut:

V-Cut degree 20,30,45,60

Capability

Bare PCB Lead Time

|

Layer

|

Sample Order

|

First Order

|

Mass production

|

|

Quick turn

|

Usual time

|

(above 30 m2) | |

|

2

|

24 hours

|

3-4 days

|

8-10 days

|

|

4

|

48 hours

|

5-6 days

|

10-12 days

|

|

6

|

72 hours

|

6-8 days

|

12-14 days

|

|

8

|

72 hours

|

8-10 days

|

16-18 days

|

|

10

|

96 hours

|

12-12 days

|

18-20 days

|

|

......

|

......

|

......

|

......

|

PCB Assembly Lead Time

Packing and Delivery

Related Keywords