Double Sided PCB Assembly

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Double-Sided Circuit Board Assembly

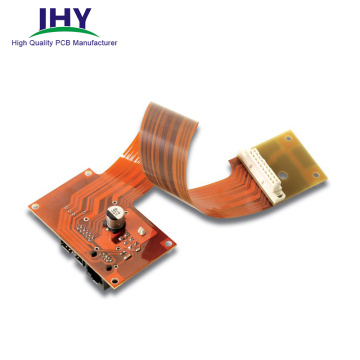

JHY PCB provides Double Sided PCB Assembly (PCBA) services as per customer specifications. Double Sided PCB Assembly is a time consuming process, as it involves repetition of the entire parts-placement process on both sides of the PCB. Despite the complexity of double-sided assembly, JHY PCB offers the service for the satisfaction of our consumers and many of them contact us to obtain cost advantages along with the high quality services Bittele provides.

We have an involved, intelligent, and hard-working team available to deliver important and critical double-sided PCB assembly services. Our capabilities include assembling of through-hole components (THT), surface-mount components (SMT), mixed technology components (THT and SMT), double-sided mixed technology, double-sided SMT assembly, high density pin connectors, 0201 package sizes or big size components, etc. for the desired volume.

We provide Double Sided PCB services for prototype as well as small and medium quantity orders. We also have the capability to offer 2-sided assemblies for other volumes as well. The complete details of our service capabilities can be obtained from our staff. After learning your requirements, we will provide you the required services along with lead-free processing.

We are skilled in lead-free processing for two-sided PCB assembly. But, we provide lead-free soldering only upon your specific instructions. In order to give you this exclusive service, we have created two dedicated production lines. We employ expert engineers and have trained them to execute production processes as per RoHS soldering guidelines.

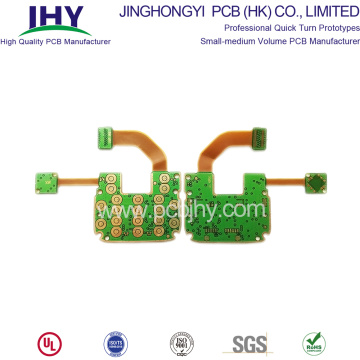

JHYPCB is double sided Flexible PCB, Double Sided Flex PCB manufacturer, Welcome to send your PCB file to us, Get the best quote now !

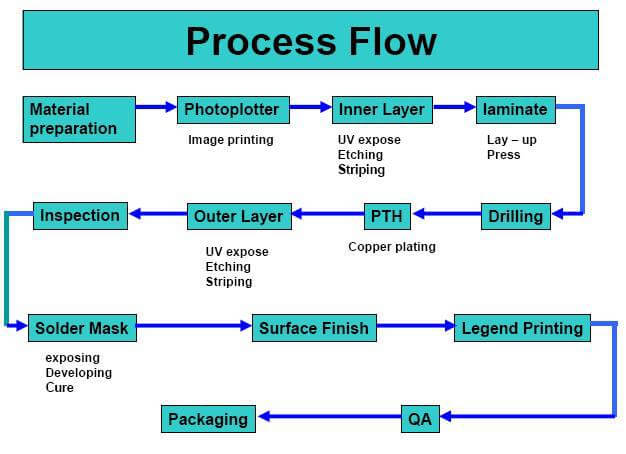

Double-sided PCB Assembly Process

A. Incoming Inspection=> Screen Solder Paste Printing on PCB A side(Dispense surface mount adhesives => Surface Mounting => Drying(Solidifying) => Reflow Soldering on A side => Clean out => Plate Turnover => Screen Solder Paste Printing on PCB B side(Dispense surface mount adhesives) => Surface Mounting => Drying => Reflow Soldering(Better on B side) => Clean out => VI&AOI => Rework/Repair.

This process is suitable for mounting large SMDs on both sides of the PCB such as PLCC.

B. Incoming Inspection=> Screen Solder Paste Printing on PCB A side(Dispense surface mount adhesives => Surface Mounting => Drying(Solidifying) => Reflow Soldering on A side => Clean out => Plate Turnover => Screen Solder Paste Printing on PCB B side(Dispense surface mount adhesives) => Surface Mounting => Solidifying => Wave Soldering on B side => Clean out => VI&AOI => Rework/Repair.

Related Questions Maybe You Want to Know

What is a double sided PCB?

Double Sided PCB. Double Sided PCBs (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to higher technology applications. They allow for closer (and perhaps more) routing traces by alternating between a top and bottom layer using vias.

What is printed circuit board assembly?

Printed circuit board assembly, also known as PCBA, is the process of soldering or assembly of electronic components to a PCB or printed circuit board. Once electronic components are soldered, the board is called Printed Circuit Assembly (PCA) or Printed Circuit Board Assembly (PCBA).

What is PCB assembly process?

Printed Circuit Boards Assembly (PCBA) Process. Electronics are an integral part of our daily lives. Everything from our smart phones to our cars includes electronic components. A PCB with components mounted on is called an assembled PCB and the manufacturing process is called PCB assembly or PCBA for short.

What is Assembly top in PCB?

pcb layers in layout. TOP LAYER [In solder mount assembly, the layer which are at the top of PCB where are mounted, called TOP layer. This layer is normally green in colour." 3. BOT (BOTTOM) LAYER [In through hole, where the components are soldered, this layer is called BOT (BOTTOM) layer."

Related Keywords