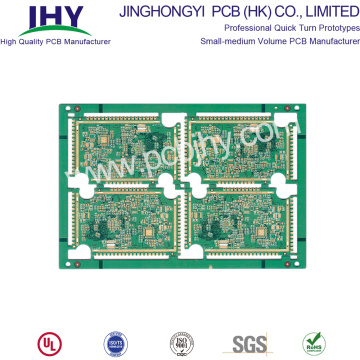

High TG FR4 94V0 Multilayer PCB Board

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Reasons for using HIGH TG PCB

Ordinary PCB materials at high temperatures, not only will be softened, deformation, melting and other phenomena, but also the mechanical and electrical properties decline sharply. The higher Tg point means a higher temperature requirement during lamination. And the boards will be hard and crisp, which will affect the hole and the electrical properties. Circuit board material must flame-resistant, it can't be burned at a certain temperature and only be soften. The temperature point is called the glass transition temperature (Tg).

Typical application areas

- Multilayer boards with many layers

- Industrial electronics

- Automobile electronics

- Fineline trace structures

- High temperature electronics

Tg Value

The glass transition temperature (Tg) is an important normative dimension for the base material that determines the temperature at which the resin matrix converts from a glassy, brittle condition into a soft, elastic one.

The Tg value of the base material sets here an upper boundary, at which the resin matrix decomposes and a subsequent delamination occurs. The Tg is thus not the value of the maximum operational temperature, but rather that which the material can endure for only a very short time.

A guideline for a continuous thermal load is an operating temperature approximately 25°C below the Tg.

When the glass transition temperature (Tg) is over 170°C, it is referred to as a high Tg material.

High Tg materials have the following properties:

- High glass flow temperature value (Tg)

- High temperature durability

- Long delamination durability

- Low Z axis expansion (CTE)

Applications for High-Temp PCBs

If you are working with high power density designs whose heat generation is likely to overwhelm your heat sinks or other heat management methods, a high-TG PCB is really the only answer. Trying to reduce the heat generation of your PCB may affect the weight, cost, power requirements or size of your application, and it is usually much more cost-effective and practical to simply start with a high-temperature heat-resistant PCB.

High temperatures can be disastrous for unprotected PCBs, damaging dielectrics and conductors, creating mechanical stresses due to differences in thermal expansion rates and ultimately causing everything from inconsistent performance to total failure. If your applications are in any danger of subjecting your PCBs to extreme temperatures or the PCB is required to be RoHS Compliant, it will be in your best interest to look into high-TG PCBs.

2 Layer High TG PCB. The material is FR4, TG 170.1oz finished copper thickness. Finished board thickness is 1.6mm. Green solder mask.White silkscreen. Surface Finish is ENIG 1u". Min.trace width is 0.1mm. Min.trace space is 0.1mm.

Type

High TG PCB

Layers

4L

Base Material

FR4 Tg170

Dielectric

Prepreg

Board Thickness

1.6mm±10%

Copper Weight

1oz

Surface Finish

ENIG 1U"

Minimum trace Width/Spacing

0.2/0.15mm(8/6mils)

Solder Mask Color

Green

Silkscreen Color

White

Min. Hole Size

0.25mm

Flame Retardant Properties

94 V-0

Application

Communication

High TG PCB Board manufacturer

Learn more about JHY PCB by exploring the manufacturing capability of High TG PCB below. We can do more than you can imagine.

|

Material |

TG |

Td |

CTE-z |

Td260 |

Td288 |

|

(DSC, °C) |

(Wt, °C) |

(ppm/°C) |

(min) |

(min) |

|

|

S1141 (FR4) |

175 |

300 |

55 |

8 |

/ |

|

S1000-2M (FR4) |

180 |

345 |

45 |

60 |

20 |

|

IT180A |

180 |

345 |

45 |

60 |

20 |

|

Rogers 4350B |

280 |

390 |

50 |

/ |

|

High TG PCB Board fabrication

Why choose us?

- Save money&time! Achieve peace of mind!

- A professional and trustworthy PCB prototype manufacturer.

- Fastest PCB Prototype.

- One stop solution for various PCB&SMT Stencil.

- Low cost for simple PCB.

- Affordable price for high-tech PCB.

- Minimum orders 1pcs.

- 24-hour online customer service.

- Professional PCB engineer for one-to-one service.

- Shipment on time.

- Guarantee good service and quality from PCB quotation to delivery.

Product & Service

- Quick Turn PCB

- Rigid PCB

- Flexible PCB

- Rigid-flex PCB

- Aluminum PCB

- PCB Stencil

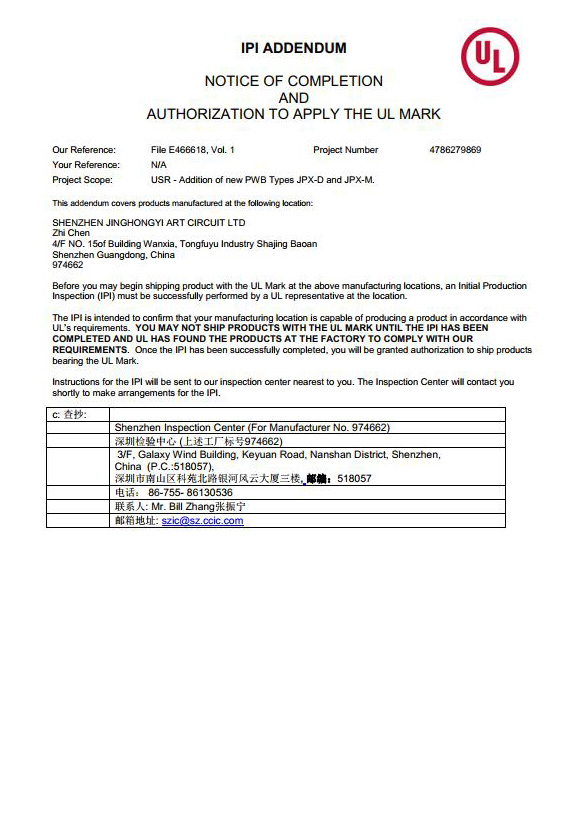

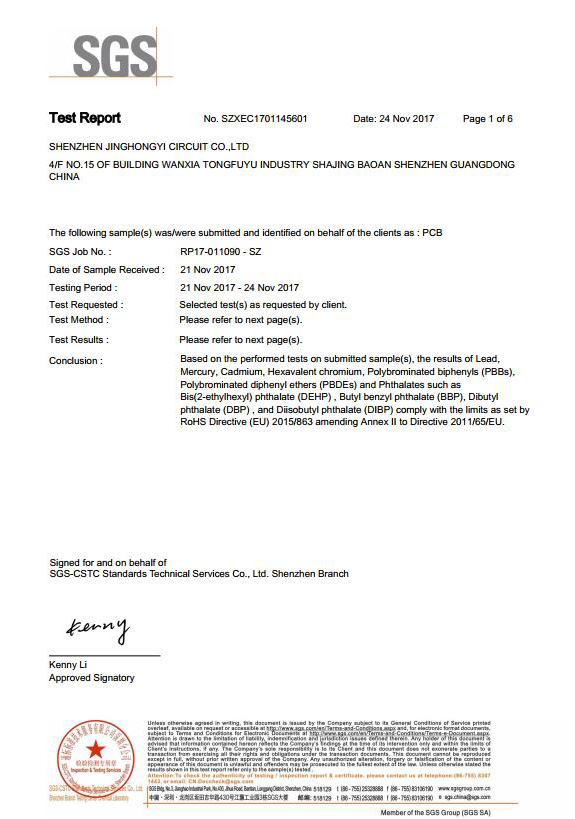

Certification(UL:E466618, TS16949, ISO9001.RoHS)

Electronics Fair

We took part in the famous exhibitions (As a PCB manufacturer) over the past years and got high appreciation from the top experts and customers, as well as cooperated tightly with them.

PCB Shipment

JHY PCB offers flexible shipping methods for our customers, you may choose from one of the methods below.

Shipping Process

After production and testing, your PCB orders will be sent to our shipping department. As the quick turn PCB manufacturer, JHY PCB shipping department will ship your PCB quickly without any pending.

JHY PCB 's Packing Way

- Use one professional PCB vacuum bag, with desiccant inside. Vacuum compressed totally.

- Paste label and RoHs mark. Use second vacuum bag to protect boards again, vacuum compressed, make sure no exception.

- Microsection report and Tin testing board are put together with PCB in cartons.COC (Certificate of Conformity) will be sent to customer by email in PDF.

- Several layers of thick EPE(Expand aple poly ephylene) are filled fully in gaps between PCBs and cartons. Thickness of 1 layer EPE is 10mm.

- Neutral Packing is adopted if no special requirements. Strong and thick cartons(Thickness:10mm,7 layers). Different sizes of cartons are designed to meet demand of different PCB size. All package are within weight limit of cartons. For mass production order, no exceed 21kg per carton normally.

- All cartons sealed with strong adhesive tape should be sealed twice so as to make them more durable.

- Solid PP/PET strapping is used outside of cartons.

- Shipping mark, fragile mark and postcode label are all pasted clearly.

Whatever we do or whatever we think of is to make sure boards are shipped to customer safely and quickly.

How to ship your PCB?

- Firstly, JHY PCB shipping department will print order address and invoice.

- Secondly, JHY PCB will set the shipment information on the Logistics company website.

- Thirdly, the Logistics company staff will collect the package from JHY PCB and ship it to you.

Shipment Term

With the purpose of better customer service and meeting the customer demand, JHY PCB provides following shipping methods.

JHY PCB is experienced in exporting. For PCB Prototype and small-medium volume PCB order, we have stable and long-term good relationship with forwarder, such as international express company DHL, FedEx, TNT, UPS. For mass production order, we have famous and reliable shipping company for support.

FAQ

Q1: What is your minimum order quantity?

A: Our MOQ is 1 PCS.

Q2: Do you accept PCB design with different boards on one panel?

A: Of course, we can do different boards on the same panel.

Q3. Are my Gerber Files safe?

A: We protect the intellectual property for customers in the whole process. All documents from customers are never shared with any third parties.

Q4: What is needed for quotation?

A: Quantity, PCB Gerber file, Technical requirements(material, board thickness, surface finish, copper thickness, solder mask color, silkscreen color,...)

Q5.How to quote shipping cost?

A: The shipping cost is determined by the shipment way(forwarder name, delivery days), destination, weight&dimension of packages. If you use your own forwarder, please inform us.

Related Keywords