Single Side FPC Immersion Silver Circuit Board

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Product Description

Product Description

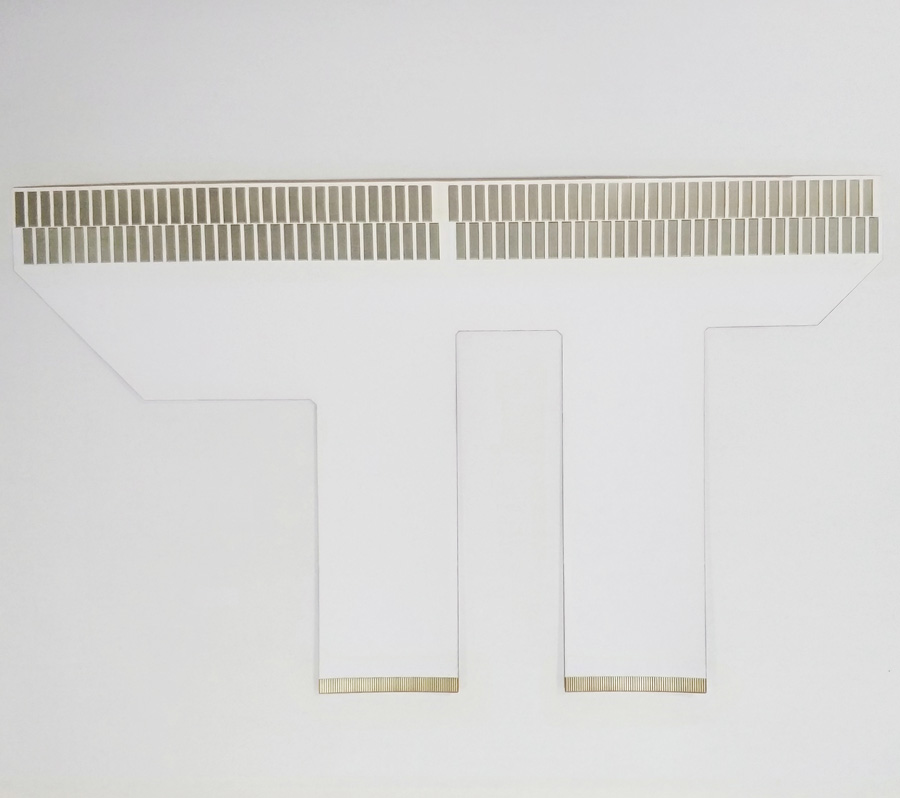

Single Side FPC Immersion Silver Circuit Board, Immersion Silver PCB, Immersion Silver PCB Process with High Quality Fabrication Manufacturing and Supplier.

PCB Surface Treatment Process

At present, the environmental problems involved in the PCB production process are particularly prominent. Lead-free and halogen-free will affect the development of PCB in many aspects. The change in PCB surface treatment technology is not great, but it should be noted that long-term slow change will lead to huge change. With more and more environmental protection calls, PCB surface treatment technology will change greatly in the future.

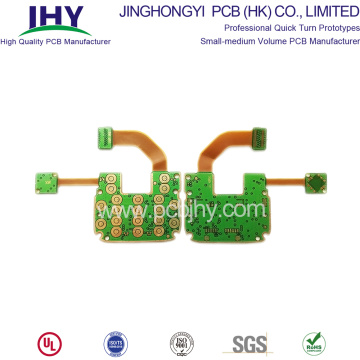

Flexible Immersion Silver PCB

Common PCB surface treatment processes include: HASL (hot air solver leveling), OSP (organic coating), electroless nickel / immersion gold, immersion silver, immersion tin, etc.Immersion silver Process

The immersion silver finish is between OSP and electroless nickel/immersion gold, which is simple and fast. Immersion silver is not a thick armor for PCB. Even if exposed to heat, humidity, and pollution, it can still provide good electrical performance and maintain good solderability, but it will lose luster. Because there is no nickel under the silver layer, silver immersion does not have all the good physical strength of electroless nickel plating/immersion gold.

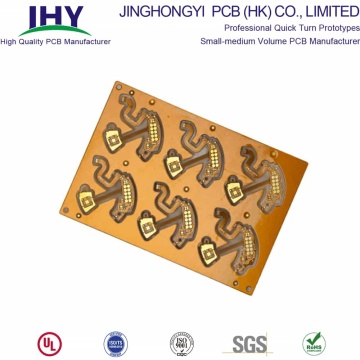

Immersion Silver PCB

Immersion Silver is a displacement reaction, it is almost submicron pure silver coating. Sometimes there are some organics in the process of immersion silver, mainly to prevent silver corrosion and eliminate silver migration. Generally, it is difficult to measure the thin layer of organics. The analysis shows that the weight of the organism is less than 1%.Immersion silver is cheaper than immersion gold. If the PCB has functional requirements for connection and needs to reduce costs, immersion silver is a good choice. In addition, because of the good flatness and contact of the silver, it is better to choose the immersion silver process.

Immersion silver is widely used in communication equipment, automobile, and computer peripherals, and also in high-speed signal design. It can also be used in high-frequency signals because of its excellent electrical properties which cannot be matched by other surface treatments.

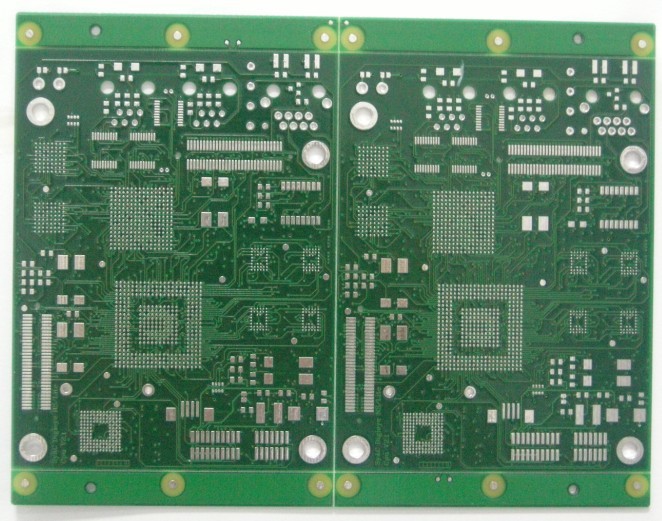

Jinghongyi PCB recommends using the immersion silver process because it is easy to assemble and has good checkability. We are able to provide you with the manufacturing services of Immersion Silver PCB. Moreover, Jinghongyi PCB is engaged in PCB prototype and small and medium batch PCB manufacturing and one-stop turnkey PCB assembly service for many years. It has accumulated rich manufacturing experience and understand our assembly services and capabilities, please click here.

Related Keywords

Related Keywords