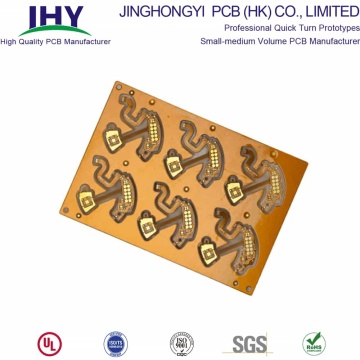

Double Sided FPC Printed circuit board

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Double Sided FPC Printed circuit board, Double Sided FPC Circuit Board Manufacturer

There are four common types of FPC: single-sided flexible PCB, double-sided flexible PCB, multilayer flexible PCB and HDI rigid-Flex PCB.

FPC flexible printed circuit is a highly reliable and excellent flexible printed circuit based on polyimide or polyester film. With the further increase of competition, the price war of PCB becomes more and more fierce, and the price of common PCB is lower and lower, but there is still a certain market for FPC.

One side flexible PCB and Double sides flexible PCB are common on the market.

Product features of flexible PCB:

1. It can be bent, folded and wound freely, and can move and stretch freely in three-dimensional space.

2. Good heat dissipation performance, can use FPC to reduce volume.

3. Realize lightweight, miniaturization and thinness, so as to achieve the integration of component device and wire connection.

FPC applications

MP3

MP4 player

Portable CD player

VCD

DVD

Digital camera

Cell phone and cell phone battery

Medical equipment

automobile

Aerospace field

FPC has become an important type of epoxy copper clad laminate with flexible function. The flexible copper clad laminate (FPC) based on epoxy resin is widely used because of its special function, and is becoming an important type of epoxy resin based copper clad laminate.

Development prospect of single sided FPC:

1. thickness. The thickness of single sided FPC must be more flexible and thinner.

2. Bending resistance. Bending is an inherent feature of single-sided FPC. In the future, single-sided FPC must be more resistant to bending.

3. price. At present, the price of single-sided FPC is much higher than that of PCB. If the price of FPC comes down, the market will be much wider.

4. Process level. In order to meet the requirements of many aspects, the process of single-sided FPC must be upgraded, and the minimum aperture, minimum linewidth/line spacing must meet higher requirements.

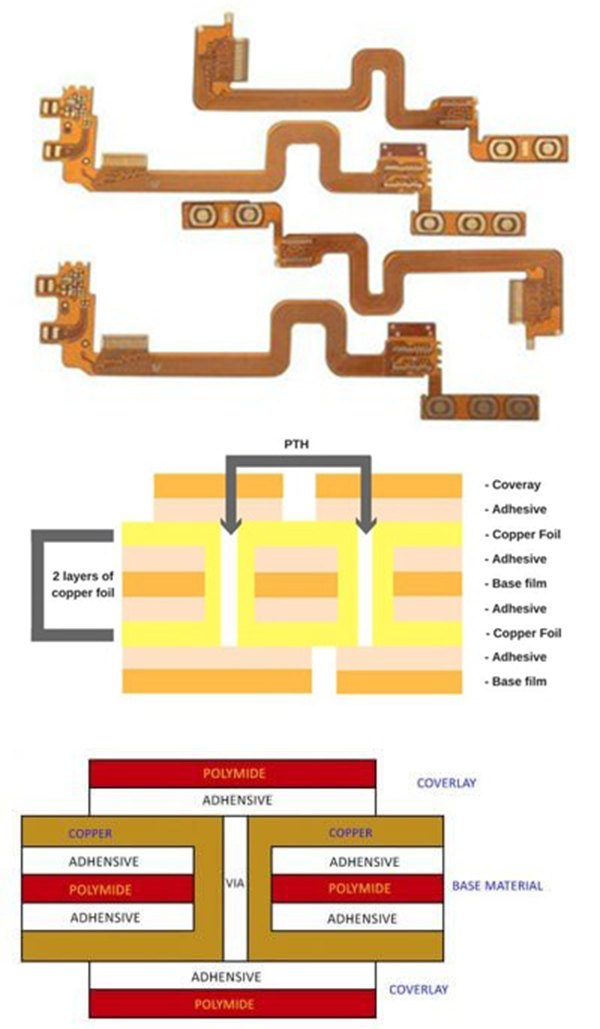

Double sided flexible printed circuit board

The double-sided flexible PCB has two conductive layers, between which there is a polyimide insulating layer. The outer side of the conductive layer may be exposed or have a cover, such as a copper pad. Layers are usually connected by electroplated through holes to meet the design and use function of flexibility, but other methods can also be used. The covering film can protect the single and double-sided wires and indicate the location of the components. Like single-sided flexible circuits, double-sided flexible PCBs can support other components, such as pins, connectors, and stiffeners.

Double sided flexible PCB stacking mode:

Application of double-sided Flex PCB

The double sided Flex PCB can be used to:

Ground and power plane applications

Dense surface mount assembly

LCD module for mobile phone

Digital camera

AV and computer optical pickup

Audio Jack

Feature Phone

Smart Phone

Sensor

LCMl Hinge

Touch Panel

Antenna

Wifi

Sidekey

Slider

Keypad

Tablet PC

E-Book

Prospect of double-sided FPC circuit board:

1. Advantages: high density, small volume, light weight and high reliability

2. Disadvantages: high cost, long cycle, high reliability detection means required

Jinghongyi PCB, a professional PCB prototype and small and medium-sized batch production manufacturer, has nearly 10 years of experience. If you are looking for flexible PCB manufacturing and assembly services, please contact us. We can meet your production demand and delivery time.

The following is the FPC we have manufactured and the production process we have adopted

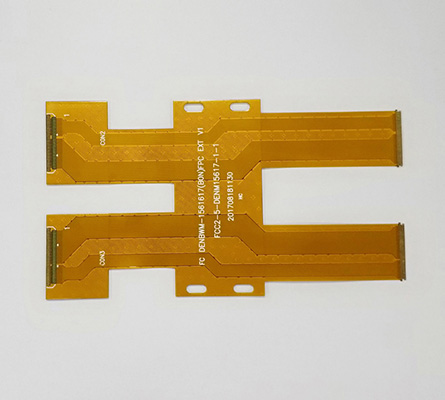

Double Sided FPC Cable

Application: test fixture

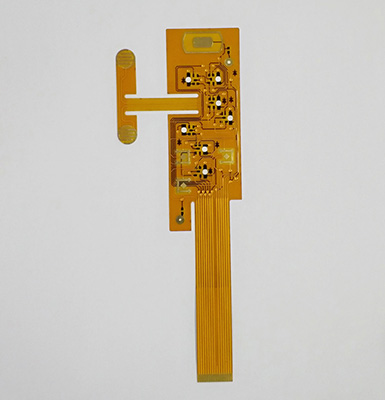

Double Sided FPC Circuit Board

Application: communication equipment, tablet computer

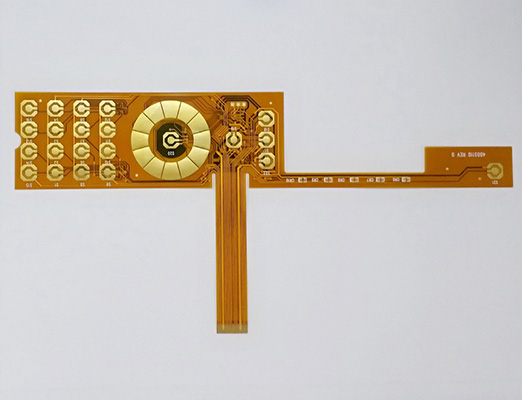

Double-Sided Flex PCB

Application: medical equipment

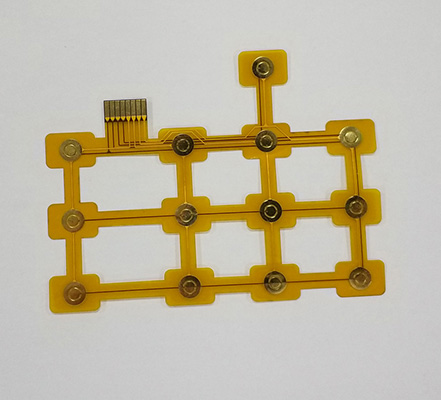

Double Sided FPC Test Board

Applications: testing

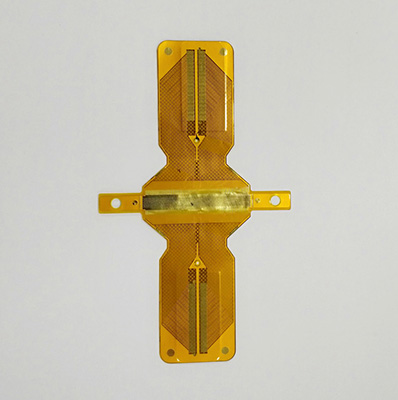

Double-Sided FPC Printed circuit board

Application: medical equipment

Application: communication equipment, tablet computer

Type: FPC double sided board

Size: 158.29 * 33.05mm

Line width / line distance: 0.25mm/0.2mm

Tolerance: ± 0.03mm

Thickness: 0.1mm

Reinforcement: front and back 0.225 pet reinforcement

Surface treatment: immersion Gold 1 Mil

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: double sided FPC cable

Minimum line width / line spacing: 0.09mm/0.05mm

Minimum drilling: 0.2mm

Thickness of finished product: 0.15 + / -0.03mm

Reinforcement: front and back 0.3mmfr4 reinforcement

Surface treatment: Immersion Gold (120 mil thick nickel; 1 mil thick gold)

Lead time: 24-48 hours for urgent prototype PCB/1-3 days for sample shipment

Type: double sided FPC circuit board

Line width / distance: 0.12mm/0.12mm

Size: 71 * 94mm

Tolerance: ± 0.03mm

Thickness: 0.1mm

Reinforcement: 0.225mm pi reinforcement on the opposite side

Shrapnel: C5.0 * 5.0 * 1 elastic force 250

Surface treatment: Immersion Gold 1 mil

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: double sided FPC flexible board

Size: 70.5 * 117.2mm

Minimum drilling: 0.15mm

Plate thickness: 0.1mm

Reinforcement: 0.5mm FR4 on the back of welding pad

Surface treatment: Immersion Gold 1 mil

Line width / distance: 0.1mm/0.08mm

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: double sided FPC test

Minimum line width / distance: 0.3mm/0.25mm

Minimum borehole: 0.15mm

Plate thickness: 0.15mm ± 0.03mm

Reinforcement: 0.8mm fr4 reinforcement on the opposite side

Surface treatment: Immersion Gold

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: Double-sided FPC circuit board

Size: 114.11*236.16 mm

Minimum drilling: 0.2mm

Plate thickness: 0.23mm

Reinforcement: 0.15mm PI reinforcement on the back of finger

Surface treatment: Immersion Gold 1 mil

Line width / line spacing: 0.17mm/0.2mm

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Flexible PCB Manufacturing Capability

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film |

|

| Silkscreen Color | White, Black, Yellow |

|

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

Related Keywords