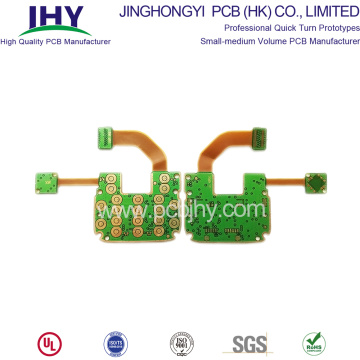

Flexible PCB Circuit Service

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

What is Flexible PCB circuit?

Flexible printed circuit boards, also called Flexible PCBs or Flex PCBs, derive their name for their ability to enable the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform to the circuit board. Flex boards are characterized by a distinctly patterned printed circuitry and component arrangement highlighted by a malleable base material.

Here is some common terminology used for flexible printed circuits

- flexible PCBs

- flexible printed circuit board

- flex circuits

- flexible circuits

- flexi

- flexible printed circuitry

Flexible printed circuit boards offer a number of potential benefits including:

- Saving Space. Flex PCB design requires only about 10 percent of the space and weight of an ordinary circuit board assembly, offering greater installation and packaging freedom. The inherent flexibility also permits tighter bend capabilities.

- Maximum Reliability. A flexible printed circuit board requires fewer interconnects, which in turn requires fewer contact crimps, connectors and solder joints. Simply put, a flexible PCB board does not contain as many potential sources for failure, which enhances their reliability.

- Enhanced Capabilities. The flexible printed circuits boards are compatible with virtually any type of connector or component and works well with options such as ZIP connectors. They also perform extremely well in extreme temperatures and offer superior resistance to radiation and chemicals.

- Cost Savings. Cost-saving advantages of Flexible PCBs include reduced material and packaging demands, lower parts replacement costs and assembly errors that could result in the need for repairs.

When to Use flexible PCB?

- Dynamic flexing applications

- Unusual folding and forming applications

- Installation/service applications/repair

- Limitations on space/thickness

- Installation/service flexing

At JHY PCB, we specialize in the fabrication and assembly of flexible PCB products for use in the manufacturing of medical devices and various types of telecommunication and industrial equipment.

Our custom PCB manufacturing capabilities allow us to develop and produce a top-performing flex PCB that meets your unique requirements.

We can also work with you to produce a custom flex PCB prototype that will significantly improve your prospects of a successful project outcome.

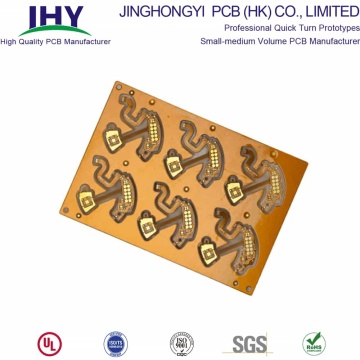

For Flexible PCB Manufacturing detailed capabilities, please refer to the following form.

We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film |

|

| Silkscreen Color | White, Black, Yellow |

|

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

A key reason why JHY PCB is widely regarded as a top PCB manufacturer is our unwavering commitment to quality. Our experienced team checks each design and takes the time to review it with you prior to production.

This ensures the circuit design is ready for manufacturing, and your boards will deliver the performance you expect. We guarantee the quality of our flex PCB parts and components.

Helpful Resources

Single Sided Flexible PCB

2 Layer Flexible PCB

Double Sided Flex PCB

MultiLayer Flexible PCB

Prototype Flexible PCB

Flexible PCB Board Manufacturer in China

- Use one professional PCB vacuum bag, with desiccant inside. Vacuum compressed totally.

- Paste label and RoHs mark. Use second vacuum bag to protect boards again, vacuum compressed, make sure no exception.

- Microsection report and Tin testing board are put together with PCB in cartons.COC (Certificate of Conformity) will be sent to customer by email in PDF.

- Several layers of thick EPE(Expand aple poly ephylene) are filled fully in gaps between PCBs and cartons. Thickness of 1 layer EPE is 10mm.

- Neutral Packing is adopted if no special requirements. Strong and thick cartons(Thickness:10mm,7 layers). Different sizes of cartons are designed to meet demand of different PCB size. All package are within weight limit of cartons. For mass production order, no exceed 21kg per carton normally.

- All cartons sealed with strong adhesive tape should be sealed twice so as to make them more durable.

- Solid PP/PET strapping is used outside of cartons.

- Shipping mark, fragile mark and postcode label are all pasted clearly.

How to ship your PCB?

- Firstly, JHY PCB shipping department will print order address and invoice.

- Secondly, JHY PCB will set the shipment information on the Logistics company website.

- Thirdly, the Logistics company staff will collect the package from JHY PCB and ship it to you.

With the purpose of better customer service and meeting the customer demand, JHY PCB provides following shipping methods.

JHY PCB is experienced in exporting. For PCB Prototype and small-medium volume PCB order, we have stable and long-term good relationship with forwarder, such as international express company DHL, FedEx, TNT, UPS. For mass production order, we have famous and reliable shipping company for support.

FAQ

Q1: What is your minimum order quantity?

A: Our MOQ is 1 PCS.

Q2: Do you accept PCB design with different boards on one panel?

A: Of course, we can do different boards on the same panel.

Q3. Are my Gerber Files safe?

A: We protect the intellectual property for customers in the whole process. All documents from customers are never shared with any third parties.

Q4: What is needed for quotation?

A:Quantity, PCB Gerber file, Technical requirements(material, board thickness, surface finish, copper thickness, solder mask color, silkscreen color, ...)

Q5. How to quote shipping cost?

A: The shipping cost is determined by the shipment way(forwarder name, delivery days), destination, weight&dimension of packages. If you use your own forwarder, please inform us.

Related Keywords