Small thermo forming machine in machinery

-

USD32001-0 Set/Sets

-

USD3600≥1 Set/Sets

- Payment Type:

- L/C, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Yonghong road 43 Liulian Fumin industrial zone, Pingdi Town,Longgang, Shenzhen, Guangdong, China |

|---|---|

| Productivity: | 200 set/sets per year |

| Supply Ability: | If it is urgent,trying our best to shorten the time and the fastest is 5 days |

| Payment Type: | L/C,Money Gram,Western Union |

| Incoterm: | FOB |

| HS Code: | 8477409000 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Guangzhou |

Small thermo forming machine in machinery applications

Vacuum forming, commonly known as vacuforming, is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying vacuum between the mold surface and the sheet. The vacuum forming process can be used to make most product packaging, speaker casings and even car dashboards.

Small thermo forming machine in machinery features

1. Control system: The mini thermo forming machine in machinery adopts central integration control system, let feeder →heat →forming →cooling → out of mould →cutting as an automatic production line. This machine adopts import components make sure that the machine has high quality.

2. The heater control: The heater is made by stainless steel to avoid the same model machine which made by iron creates oxidizing iron fall down to material and make products useless.

3. Temperature control system: Infrared ray heating ceramic tile and independent control system ensure be heated even, inside place heat preservation material reduce calories lost and save energy sources.

4. Cold breeze system: Equipped with spray fog breeze cold system, no vibration and residual wind, expedite produce speed.

5. The thermo forming machine in machinery adopts large-scale cooling fan which can cool the products quickly.

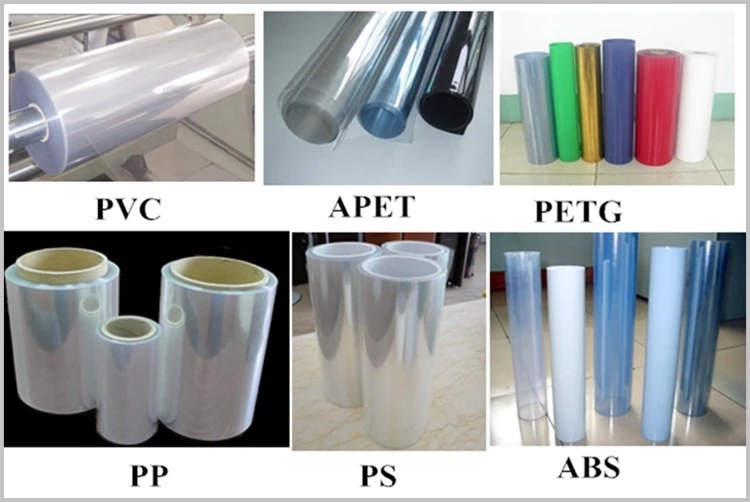

6. The manual thermo forming machine in machinery is applied to PP, PVC , PS, PET, PETG,etc.

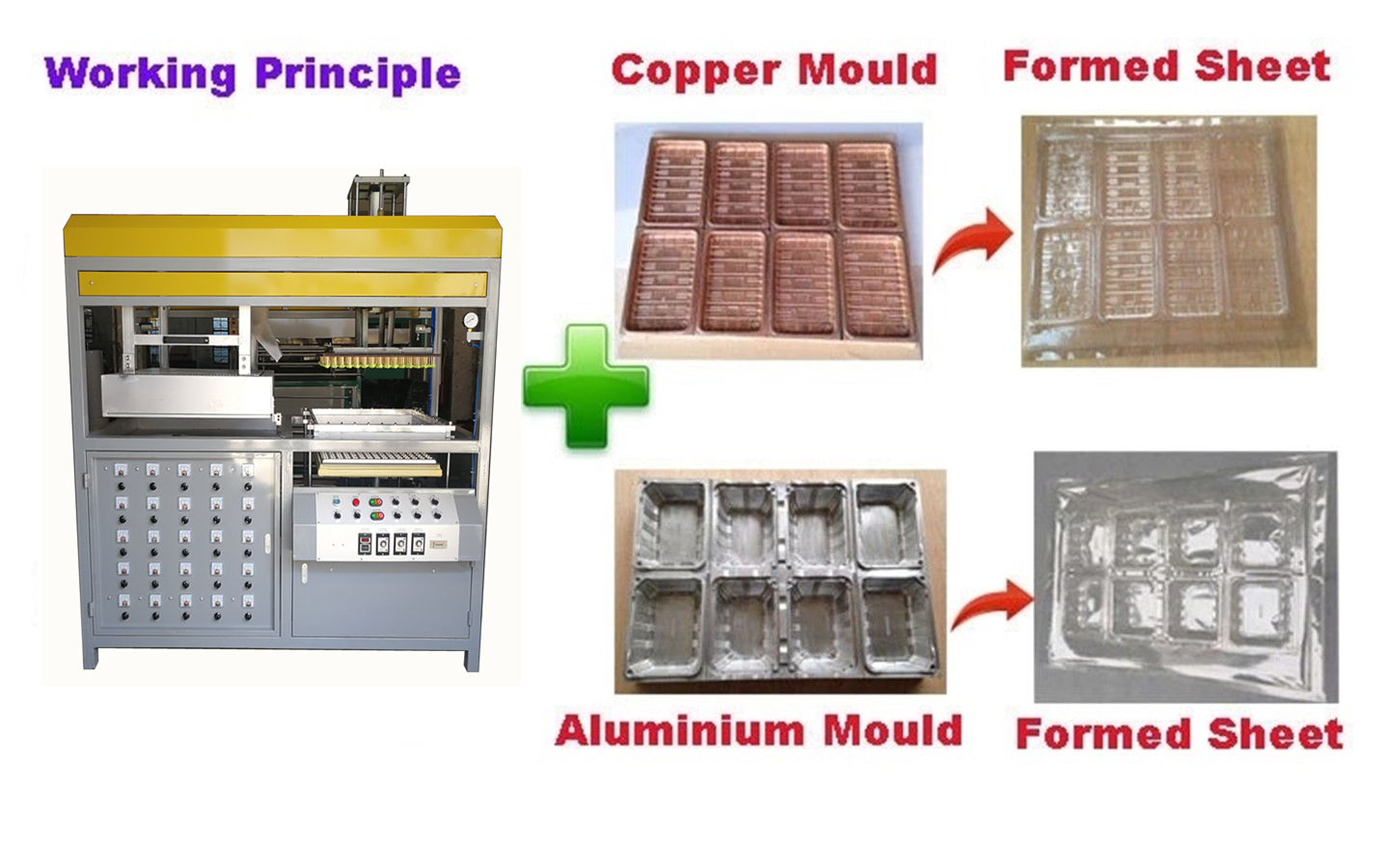

Working principles

Suitable materials

Molding and Samples

Factory information

Shenzhen Hengxing Machinery Factory specializing in the production of blister forming machine, high frequency blister welding machine,Vacuum forming machine blister sealing machine, blister folding machine,blister punching machine and Shrink packing machine and other machines. As one of the major industrial brands, HENGXING offers R&D, manufacture, sales one stop service .Since its inception, HENGXING has grown with its business partners and absorbed foreign advanced technology and experience and with our unique innovation idea and constantly make improvement of production, and we get lots of praise from customers at home and abroad. HENGXING is one of the leading brand in this area.

Located in developed economy and convenient transportation Longgang District Shenzhen. HENGXING, with its internal complete management system, serve our customer with advanced technology, professional skills and thought-full after-sales service. HENGXING always value customer`s feedback and grab the market dynamics, and constantly improve product quality and develop new product.

"Unity, dedication, innovation and development" is the main spirit of HENGXING, "Integrity-based, quality first" is our business principles. HENGXING is committed to offer customers a stable quality products in a reasonable price.

Our advantages

1. The machine is high quality and low cost.

2. Saving energy and fast delivery.

3. One year warranty.

4. Engineers available to service machinery overseas.

5. We have been in the plastic machine for more than 20 years.And we have rich experience .

6. Our workers are very professional and skilled.

Packing and Delivery

Overview

Quick Details

Condition: New

Automatic Grade: Automatic

Usage: Vacuum Forming Machine

Place of Origin: Guangdong, China (Mainland)

Brand Name:HENGXING

Model Number: HX-61

Voltage: AC380V

Power(W): 12.5KW

Dimension(L*W*H): 1800*1200 *2000mm

Weight: 650KGS

Warranty: 1 year

After-sales Service Provided: Engineers available to service machinery overseas

Max.forming size: 560*610mm

Max. forming height: 200mm

Speed: 200~300moulds/H

Thickness of material: 0.2~1.5mm

Machine size: 1800*1200 *2000mm

Oversea service: Yes

Packaging & Delivery

Selling Units: Single item

Single package size: 1900X1160X2000 mm

Single gross weight: 670.0 KG

Package Type: polywood case

Lead Time : 7

|

Model |

HX-61 |

|

Power supply |

AC380V |

|

Power |

12.5KW |

|

Max.forming size |

560*610mm |

|

Max. forming height |

200mm |

|

Speed |

200~300moulds/H |

|

Thickness of material |

0.2~1.5mm |

|

N. weight |

650KG |

|

Machine size |

1800*1200 *2000mm |

FAQ

1.If I order this machine, and how can

l learn to operate it? Do you offer any help? Would it be charged?

Answer: Shenzhen Hengxing Machinery Factory will

provide our after sales service to our customers. Once you get the machine,

meanwhile you will get our operation instruction which would detailed explain

all about the machine operation. Besides, our operation video is available for

your operation reference. If either instruction or video can not help you, and

we will arrange the our engineer contact you via international telephone

conference

or via face to face mutual video conference.

All above service is free.

The service cost in customers` country was not included if requires oversea

service.

2.About The Warranty:

Answer: One year warranty. Within one year, the initial parts or elements of

the machine broke down cause by the raw material and our hand work, Shenzhen Hengxing Machinery Factory would

replace the parts freely, but the freight charge and the consumable parts like

die, cutting mould were not included. The warranty is not valid if the machine

damage due to customers` wrong operation or caused by force majeure factors.

3.How to order raw material ?

Answer: We can help you to find raw material supplier, and also we can help you

to order if need. And if possible, we will arrange the machine and the raw

material sending to you together.

4..Do you have any other model ?

Answer: Of course . We have different choice for you, and if all our models

that`s not what you want, and you can tell us your details and we can custom

make for you. Or OEM is available.

5.What is the power supply?

Answer : Normally, there are 220v and 380v, and if you need other choice, just

tell us, and we can custom make for you. Or OEM is available.

Answer: Yes, it needs mould, Cost will be base on the size.

Related Keywords