Customized Laser Cutting Service Sheet Metal Parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 8 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 20000 Piece/Pieces |

| Supply Ability: | 100000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

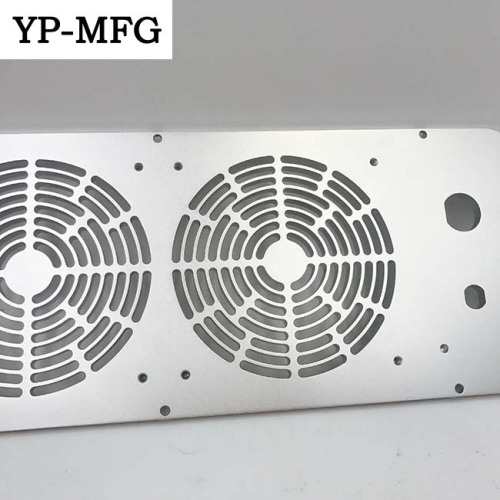

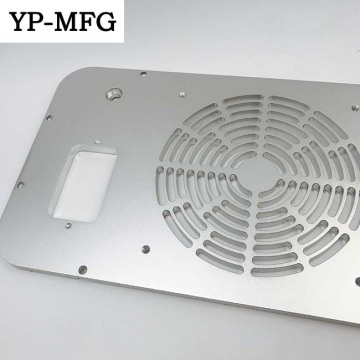

Customized Laser Cutting Service Sheet Metal Parts

For 80.5mm-86mm thick plates. Most thermal cutting techniques must penetrate a small hole in the board. On the laser stamping compound machine, a hole is punched out first with a punch. Then use laser to cut from the small hole. For laser cutting machines without a punching device, the basic method of pulse perforation is generally used-pulse perforation: the initial absorption rate of metal to 10.6urn laser beam is only 0.5% to 10%. When a focused laser beam with a power density exceeding 106W / cm2 is irradiated to the metal surface. It can quickly melt the surface in microseconds. Air or nitrogen is commonly used as an auxiliary gas, and each pulse of laser light produces only small particles. Gradually deepen, so it takes a few seconds for the thick plate to wear through. Once the piercing is completed, the auxiliary gas is immediately replaced with oxygen for cutting.

We are a custom factory,Main business scope is CNC Turning Machining,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Product images

Product information:

Material: Aluminum

Surface treatment: Anodized

Production processing: Sheet Metal Cutting

Tolerance: 0.003-0.01mm

Sample: Available

Information required for quotation:

1.2D or 3D drawings

2.Product materials

3.Surface treatment

4.Quantity

Our Service:

a) Good after-sale service, all questions will be replied within 12 hours.

b) Customized design is available. ODM&OEM are welcomed.

c) Convenient transportation and fast delivery, all available shipping ways could be applied, by express, air or sea.

d) High quality and most competitive price.

e) Advanced produce and inspecting equipments.

If you have any interested products that need to be produced, please feel free to contact me, it's my pleasure to serve you

Related Keywords