Customized Stainless Steel Sheet Metal Fabrication

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Delivery Time:

- 8 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 20000 Piece/Pieces |

| Supply Ability: | 100000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

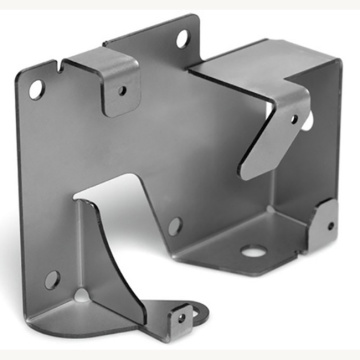

Customized Stainless Steel Sheet Metal Fabrication

Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and good mass production performance. It is widely used in the fields of electronic appliances, communications, automotive industry, medical equipment, etc. In computer cases, mobile phones, and MP3s, sheet metal is an essential component. As the application of sheet metal becomes more and more extensive, the design of sheet metal parts has become an important part of the product development process. Mechanical engineers must be proficient in the design skills of sheet metal parts, so that the design of sheet metal meets the requirements of the product. Requirements such as function and appearance can make stamping die manufacturing simple and low cost.

We also provide aluminum alloy die casting, aluminum alloy die casting, aluminum die casting, aluminum die casting, sheet metal bending, sheet metal cutting, laser cutting board, sheet metal cutting services.

|

Product Name |

Customized Stainless Steel Sheet Metal Fabrication |

|

Micro machining |

yes |

|

Tolerance |

0.003mm-0.01mm |

|

Surface finish |

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc. |

|

Precision processing |

turning, milling, drilling, grinding, wire-EDM cutting etc |

|

Material range |

Metal: Stainless Steel, Brass,Copper, Bronze, Aluminum, Steel, Carbon Steel etc. |

|

|

Plastic : PU, PVC, POM, PMMA, Nylon ,HDPE etc. |

|

QC(inspection everywhere) |

- Technicians self-check in production |

|

|

- Engineer spot check in production. |

|

|

- QC inspect after products finished |

|

|

- International sales who were trained the technical know-how spot check before shipping to ensure the quality. |

|

High-Quality |

rich manufacturing experience,competitive price |

Related Keywords