Stable ABS Molding Plastic Injection Parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 10000 Piece/Pieces |

| Supply Ability: | 200000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| HS Code: | 518100 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

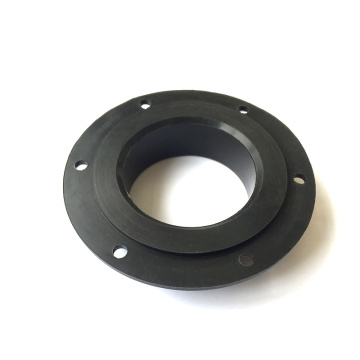

Stable ABS Molding Plastic Injection Parts

The ABS material is a graft copolymer of three monomers: Acrylonitrile, 1,3-Butadiene, and Styrene. Its molecular formula can be written as (C8H8 · C4H6 · C3H3N) x, but in fact it is often a mixture of butadiene-containing graft copolymer and acrylonitrile-styrene copolymer, of which acrylonitrile accounts for 15% ~ 35% , Butadiene accounts for 5% ~ 30%, styrene accounts for 40% ~ 60%, the most common ratio of emulsion method ABS is A: B: S = 22: 17: 61, while the ratio of B in bulk method ABS is often more Low, about 13%. The molding temperature of ABS plastic is 180-250 ℃, but it is best not to exceed 240 ℃, at this time the resin will decompose.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Product images

Product Information:

Material: ABS

Color: Black

Surface treatment: NO

Craft: Injection

Tolerance: ±0.01mm

Our Clients

YP-MFG brings many years of experience in supplying customized products from Australia, Canada, Italy, France, Germany, Japan, etc.

Information you need to provide

-

2D or 3D drawing

-

material

-

surface treatment

-

quantity

After-sales service

Free quality inspection service

100% inspection before shipment

After sending, we will track the product for you every two days until you get the product.

After receiving the goods, please test and give me feedback. If you have any questions about the problem, please contact us and we will provide you with a solution.

Contact

Stable ABS Molding Plastic Injection Parts

The ABS material is a graft copolymer of three monomers: Acrylonitrile, 1,3-Butadiene, and Styrene. Its molecular formula can be written as (C8H8 · C4H6 · C3H3N) x, but in fact it is often a mixture of butadiene-containing graft copolymer and acrylonitrile-styrene copolymer, of which acrylonitrile accounts for 15% ~ 35% , Butadiene accounts for 5% ~ 30%, styrene accounts for 40% ~ 60%, the most common ratio of emulsion method ABS is A: B: S = 22: 17: 61, while the ratio of B in bulk method ABS is often more Low, about 13%. The molding temperature of ABS plastic is 180-250 ℃, but it is best not to exceed 240 ℃, at this time the resin will decompose.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Product images

Product Information:

Material: ABS

Color: Black

Surface treatment: NO

Craft: Injection

Tolerance: ±0.01mm

Our Clients

Material: ABS

Color: Black

Surface treatment: NO

Craft: Injection

Tolerance: ±0.01mm

YP-MFG brings many years of experience in supplying customized products from Australia, Canada, Italy, France, Germany, Japan, etc.

Information you need to provide

- 2D or 3D drawing

- material

- surface treatment

- quantity

Free quality inspection service

100% inspection before shipment

After sending, we will track the product for you every two days until you get the product.

After receiving the goods, please test and give me feedback. If you have any questions about the problem, please contact us and we will provide you with a solution.

Related Keywords