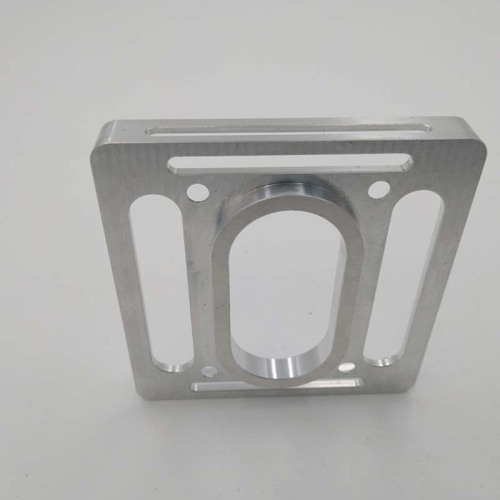

High Precision Customized Milling Aluminum Part

- Payment Type:

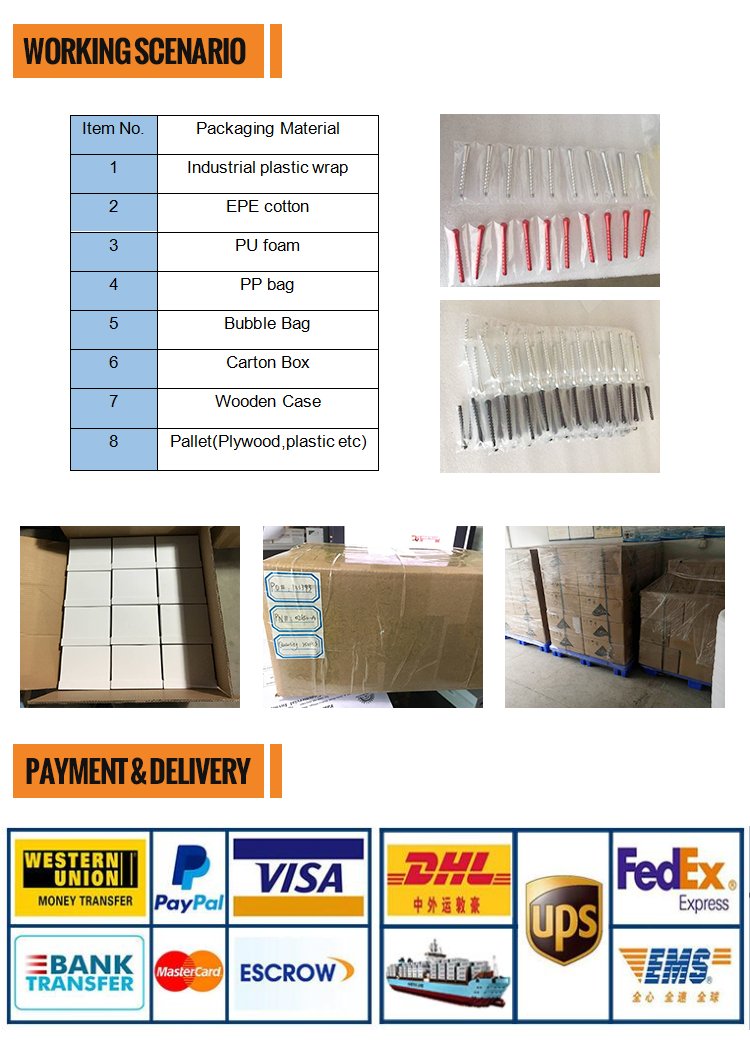

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Delivery Time:

- 8 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 20000 Piece/Pieces |

| Supply Ability: | 100000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

High Precision Customized Milling Aluminum Part

CNC machine tools, like ordinary machine tools, should also select the positioning benchmark and clamping in a whole range, which should strive to unify the design, process and programming calculation benchmark, reduce the number of clamping, and process all surfaces to be processed after one positioning clamping as much as possible, so as to avoid using the manual adjustment processing scheme of occupying machine, so as to give full play to the efficiency of CNC machine tools. All or most machining surfaces shall be machined by clamping once as far as possible. According to the part drawing, one end of ф 30mm bar stock should be clamped first, and the length of 40mm processing thread should be clamped. Process all the way to ф 23 mm at the right end of the part, and then remove the bar stock. Clamp the cylinder surface of ф 28mm, and process the arc at the other end. In this way, all machining surfaces of parts can be finished by two clamping operations, and machining requirements can be guaranteed,Titanium Cnc Milling Machining,Brass Machined Parts,Cnc Milling Machining Brass Parts,Brass Cnc Milling Machining

light metal with a silvery white metallic luster. The main feature is light, the relative density is only 1/3 of iron, and the mechanical strength of some alloys even exceeds that of structural steel. Therefore, the aluminum alloy has a large strength and weight ratio.

We are a custom factory,Main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on

our company main :cnc machining parts ,aluminum parts,cnc brass parts,sheet metal parts,stamping parts,plastic machining parts,die casting parts ,3/4/5 axis parts .

If any product meet your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention.

Material range : Metal: Stainless Steel, Brass,Copper, Bronze, Aluminum, Steel, Carbon Steel etc.

QC(inspection everywhere): - Technicians self-check in production

Surface finish: Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Tolerance 0.01-0.05mm

Precision processing : turning, milling, drilling, grinding, wire-EDM cutting etc

Related Keywords