Custom Precision CNC Machining Brass Chandelier Parts

- Payment Type:

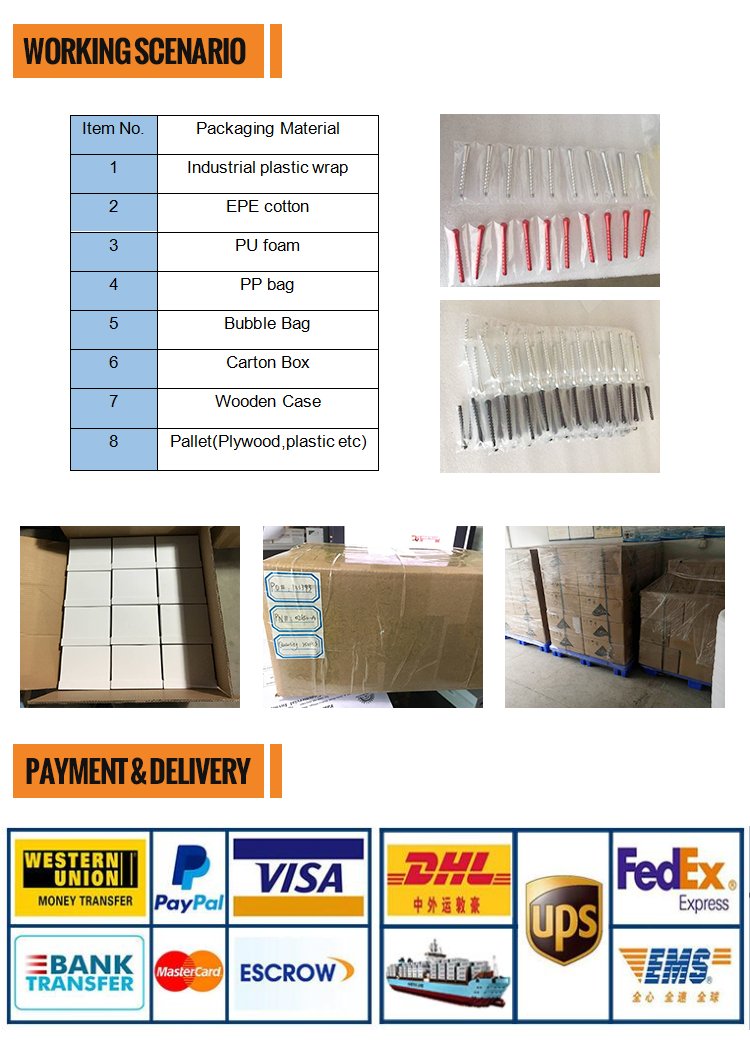

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 50000 |

| Supply Ability: | 50000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

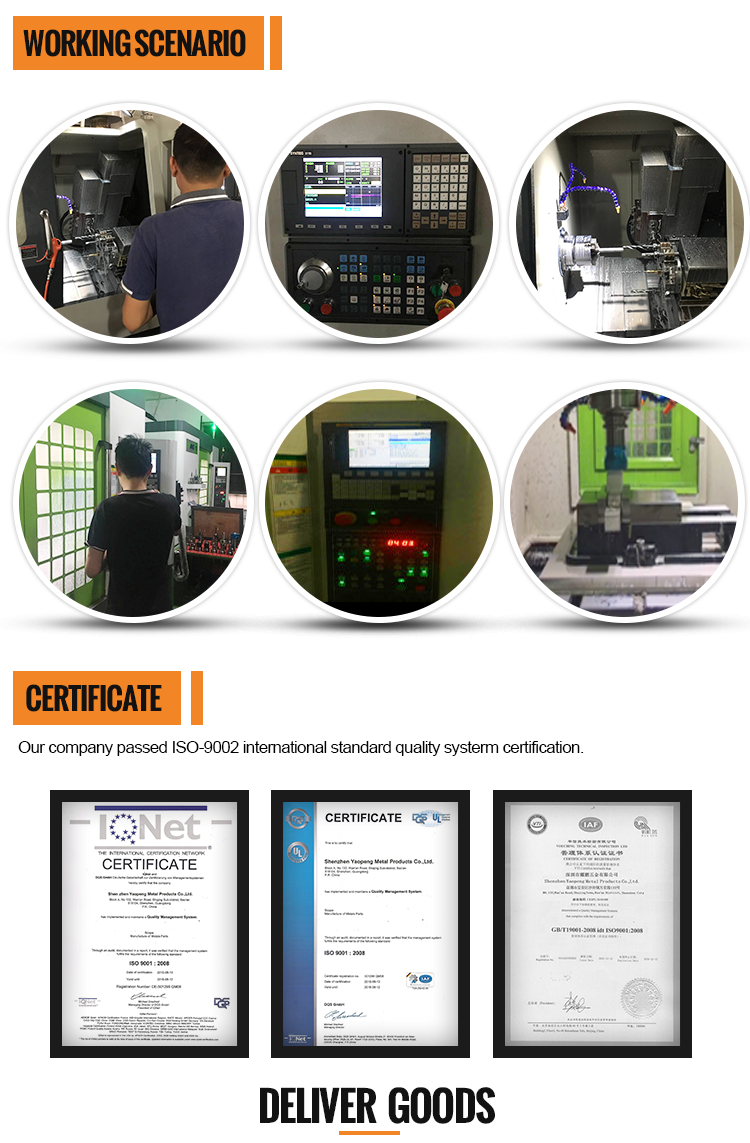

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Custom Precision CNC Machining Brass Chandelier Parts

Brass has good mechanical properties and wear resistance, and can be used to manufacture precision instruments, parts of ships, shells of guns, coins (such as five yen coins) and so on. Different zinc content will have different colors, such as zinc content of 18% -20% will be reddish yellow, and zinc content of 20% -30% will be brownish yellow. In addition, brass has a unique sound, so musical instruments such as gongs, cymbals, bells and trumpets in the east, and brass instruments in the west are all made of brass.

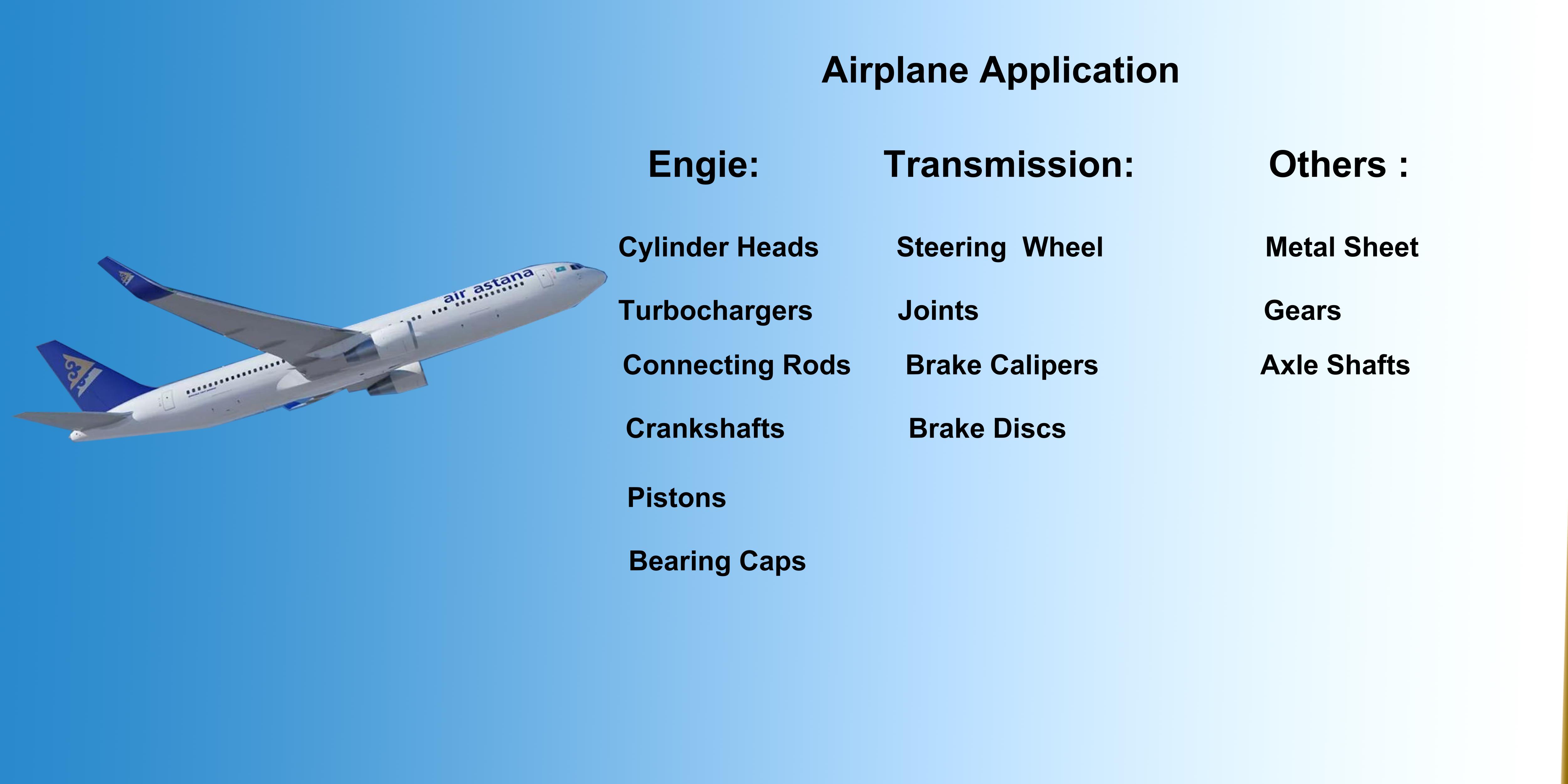

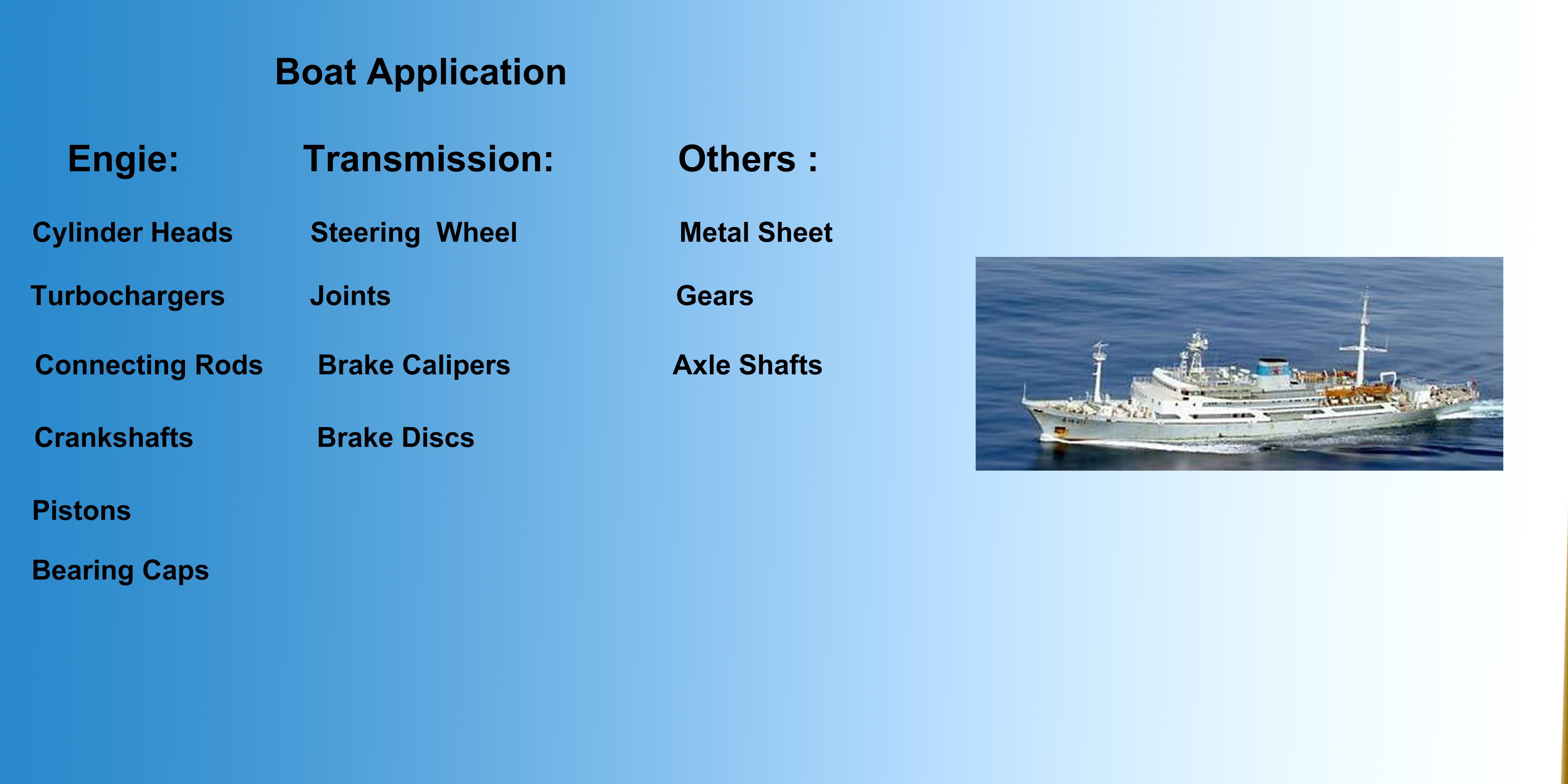

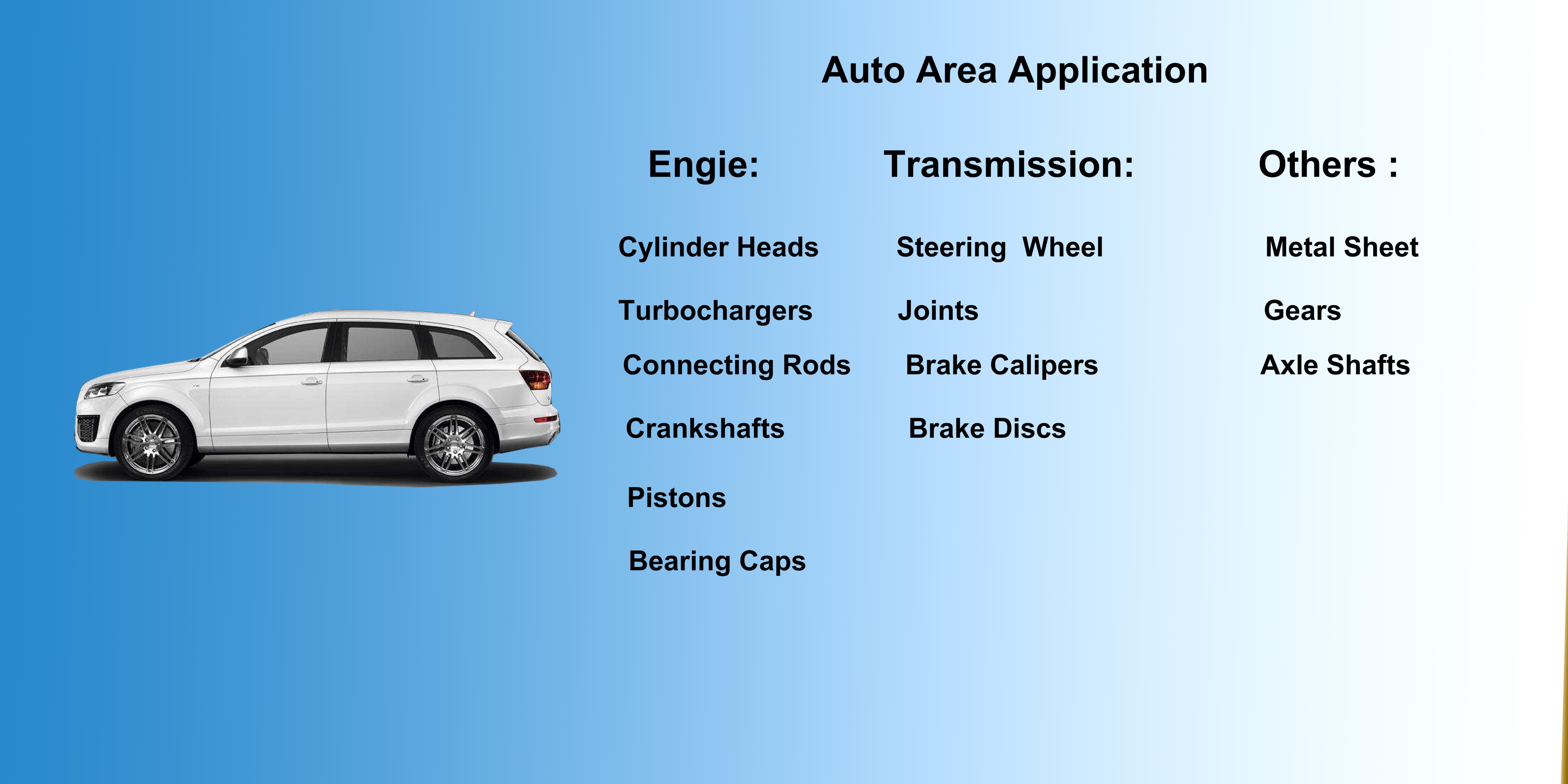

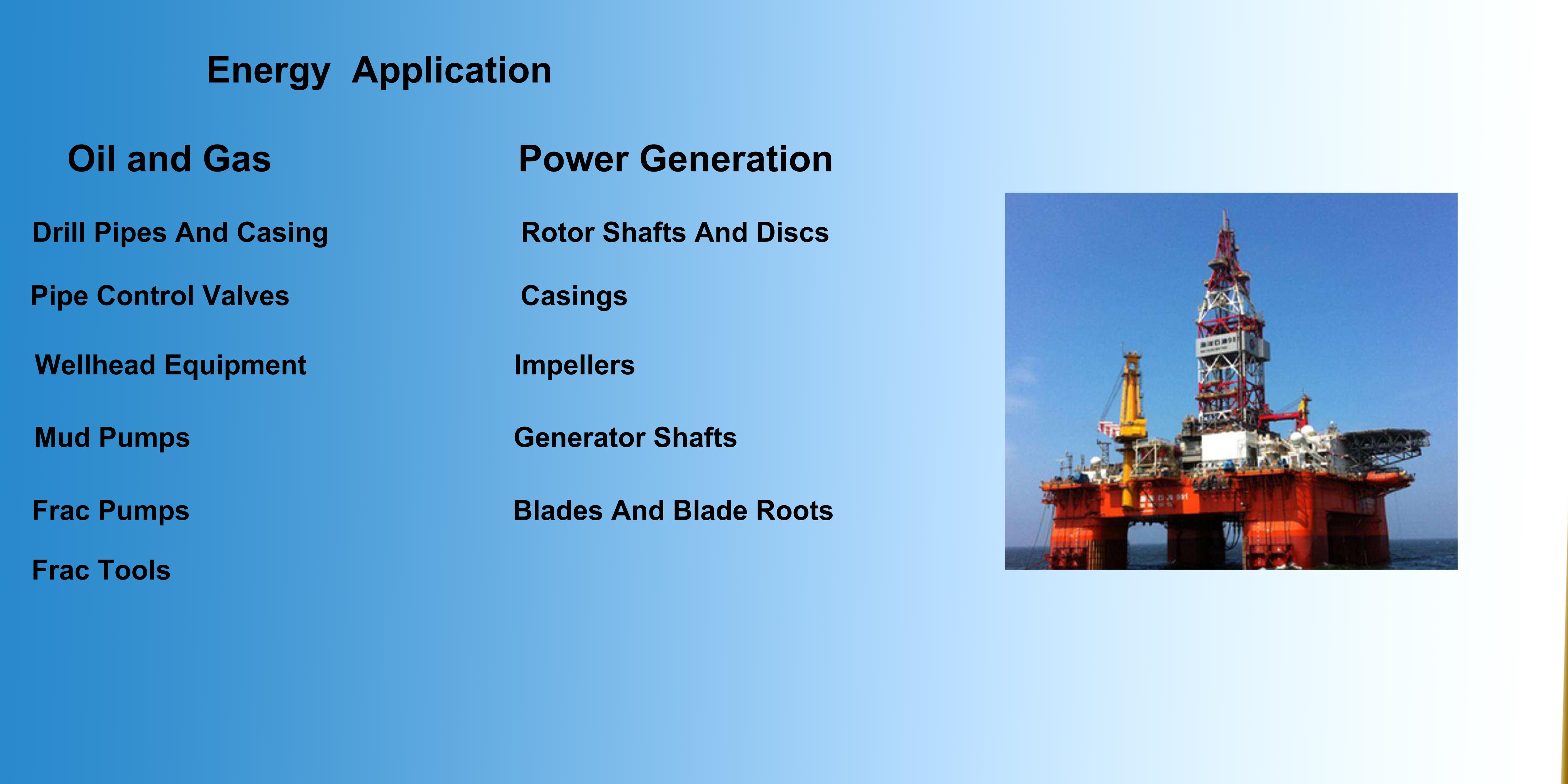

We are a custom factory,Main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

If you are interested in any of our products, please feel free to contact me. Any enquiries that you make will get a prompt response.

|

Product Name |

Custom precision cnc machining brass chandelier parts |

|

Micro machining |

yes |

|

Tolerance |

0.003mm-0.01mm |

|

Surface finish |

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc. |

|

Precision processing |

turning, milling, drilling, grinding, wire-EDM cutting etc |

|

Material range |

Metal: Stainless Steel, Brass,Copper, Brozone, Aluminum, Steel, Carbon Steel etc. |

|

|

Plastic : PU, PVC, POM, PMMA, Nylon ,HDPE etc. |

|

QC(inspection everywhere) |

- Technicians self-check in production |

|

|

- Engineer spot check in production. |

|

|

- QC inspect after products finished |

|

|

- International sales who were trained the technical know-how spot check before shipping to ensure the quality. |

|

MOQ |

1-100pcs |

|

Payment |

30% in advance, 70% before shipment |

|

Shipment terms |

1) 0-100kg: air freight priority, |

|

|

2) >100kg: sea freight priority, |

|

|

3) As per customized specifications. |

|

Hight-quality |

rich manufacturing experience,competitive price |

Related Keywords