Pressing Rivet Sheet Metal Parts Fabrication

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

- Port:

- Shekou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000 PCS |

| Supply Ability: | 5000 PCS |

| Certificate: | ISO 9001 |

| Transportation: | Ocean,Air |

| Port: | Shekou |

Pressing Rivet Sheet Metal Parts Fabrication

QL Sheet Metals Company is a certified professional sheet metal spare parts maker. We provide high quality service:

Sheet metal working; stamping fabrication; customized sheet metal pressing rivet parts producing; stainless steel sheet metal spare parts making service; producing custom sheet metal cutting parts and sheet metal pressing parts; engineering service, surface finishing services, etc.

To our customers around the globe. The company has been located in Shenzhen ( China, near to Hong Kong) with convenient transportation since 2007. We have a powerful R&D center and advanced CNC processing center, strict quality control department, skillful production department and devoted management team. We make a winning team providing the best quality products and services at affordable prices to our customers around the world.

QL offers customized products services to our customers. You could tell us your demands and requirements, then our engineers design the products what you need. Of course you could send the designing drawings to us and we make products according to your designs. We could sign the confidentiality agreement. We will keep secret about your designs. Our basic principle of project management understanding was prioritized time price and quality objectives. Win win principle was the driving force while we were working with different individuals and counterparts who come from various cultural background.

Production Description:

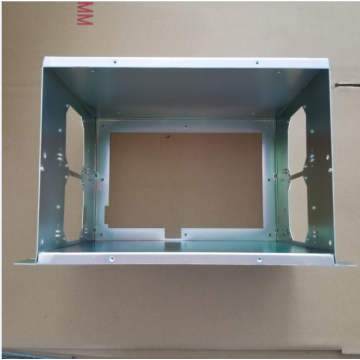

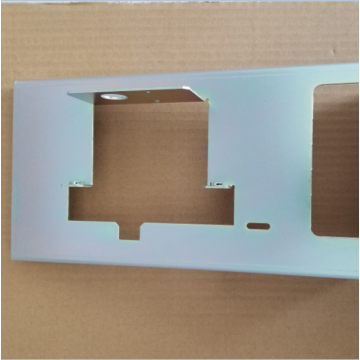

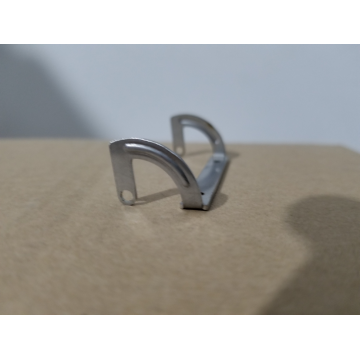

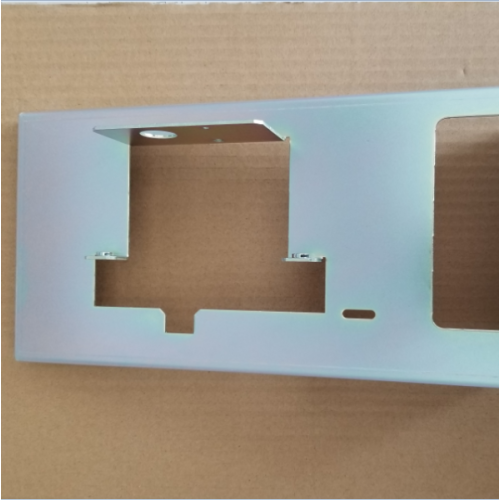

This sheet metal was made by SPCC materials and it was a part of medical device. Most of our products are spare parts of some medical equipment. These medical device spare parts are used to assemble together.

This product is made by 2.5mm, 3.0mm and 1.5mm SPCC with powder coating finish and other surface treatments. It has many parts to make so we use three different metal sheets to manufacture it.

About QL:

We are founded in 2007 with over 10 years manufacturing business experience. Just trust QL!

We own 10 million RMB registered capital and one factory with 4 floors in Shenzhen. Over 100 employees. So we have very professional workers to finish your requirement.

We are a ISO 9001:2015 certified company and have RoHS certification.

We can do OEM manufactured and customized products.

We win good reputation from customers whatever at home or abroad.

Key Profession:

We do non-standard spare parts for equipment.

Sheet metal fabricate: custom enclosure for electronic with various finish.

Metal stamping parts, sheet metal parts, etc.

Aluminum parts, stainless steel products and so on.

A professional surface finish manufacturer.

Introduction of the Product:

A plenty of surface finish for your choices.

Very strict control for surface treatments and little scratch. If the products were scratched, we would do a new one to offer.

Accurate mold as well as accurate size. We will control the tolerance by using our tools and machines.

Standard alloy composition.

Both ends of the profiles are very plain and with no burr.

Products Details:

|

Item Name |

PRESSING RIVET SHEET METAL PARTS FABRCATION QL-111 |

|

Materials |

Aluminum, Brass, Bronze, Copper, Carbon Steel, Stainless Steel, Zinc Alloy, etc. |

|

Surface Finishing |

Electro galvanized plating, Nickel plating, Chrome plating, Tin plating, Silver plating, Electrostatic spraying, Anodization, Black powder painting, Passivation, Mirror polishment, Heat treatment. |

|

Processing Methods |

CNC cutting, Bending, Welding, Spraying/Powder coating, |

|

Packing |

Standard export carton, pallets or as customer`s detailed requirements |

|

File Format |

ProE, Auto CAD, PDF, JPG |

|

Certificate |

ISO 9001 |

Related Keywords