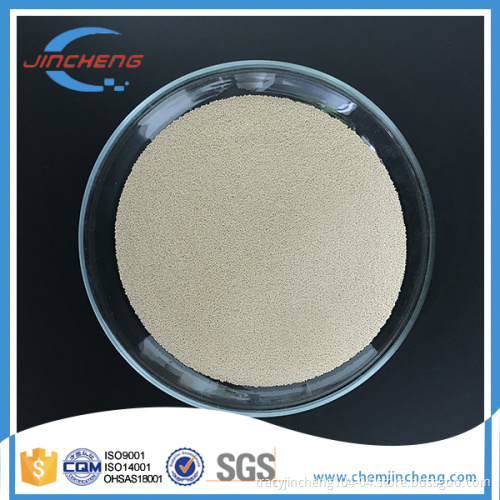

Insulating Glass Desiccants with The Excellent Performance for Moisture Adsorption

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000 Metric Tons/Year |

| Supply Ability: | 5000 Metric Tons/Year |

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

Model NO.: 0.5-0.9mm 1.0-1.5mm 1.5-2.0mm

Size: 0.5-0.9mm, 1.0-1.5mm, 1.5-2.0mm

Trademark: JINCHENG

Transport Package: 25kgs/Carton Box, or 25kgs/Carton Drum, Palletized

Specification: 0.5-1.0mm, 1.0-1.5mm, 1.5-2.0mm

Origin: China

HS Code: 3824999990

Insulating Glass DesiccantInsulating glass desiccant is the product to provide the insulating glass

Industry with the highest water capacity and lowest gas adsorption for solvent-free systems.

This insulating glass desiccant can deeply co-adsorb the resident moisture and organics in Insulating Glass, keep the IG clear and transparent even at very low temperature. More important, it can successfully avoid the tremendous air pressure unbalancely placed on the glasses, which was superposed by seasons of day-night temperature changing and the ensuring air desorption and adsorption funtion of common IG desiccant. Thus it resolves the problems of windows distortion caused by IG inflation and shrink, expanded the life span of IG windows.

Package:

1. By carton box, each box 25kgs or 30kgs net, inside airtight vacuum, palletized with wrapped.

2. By carton drum, each drum 25kgs or 50kgs net, inside airtight vacuum, palletized with wrapped.

Normal size: Φ 0.5-1.0mm Φ 1.0-1.5mm Φ 1.5-2.0mm

Feature

Very Selective Adsorption

Insulating glass desiccant has been designed as a high water capacity adsorbent with the lowest capacity of air or other gases. The highly selective pore structure of assures excellent water dew point protection while eliminating the co-adsorption of gases in the sealed air space.

Low Deflection

Because insulating glass desiccant minimizes pick up of other gases, it reduces adsorbent contribution unit deflection and stress under evere climatic conditions.

Economy and Performance

It increase gas-filled nit production rates since units can be sealed immediately after filling. In addition, the use of insulating glass desiccant maintains unit sound and heating insulation values by minimizing the adsorption of gases from the sealed space.

Homogeneous and Non-Separating

Unlike blends of two different desiccants that separate because of different component densities, insulating glass desiccant is homogeneous and uniform. Each bead is like every other. There's no need to worry about unit-to-unit variation, which can occur with blends.

Residual Moisture

Insulating glass desiccant is supplied as a fully activated Insulating Glass Adsorbent, ready for use in spacer filling operations.

|

Technical Parameter |

||||

| Item | Unit | Technical data | ||

| Shape | Sphere | |||

| Diameter | mm | 0.5-1.0 | 1.0-1.5 | 1.5-2.0 |

| Bulk density | g/ml | 0.74-0.80 | 0.72-0.78 | 0.72-0.78 |

| Static water adsorption | % | ≥20.0 | ≥20.0 | ≥20.0 |

| Crushing strength | N/piece | ≥5 | ≥15 | ≥20 |

| Dust (Turbidity meter) | ppm | ≤30 | ≤30 | ≤30 |

| Delta T (10 g/10ml) | Centigrade | ≥38 | ≥38 | ≥38 |

| Equilibrium N2 capacity | % | ≤0.2 | ≤0.2 | ≤0.2 |

| Dew point | Centigrade | <-73 | <-73 | <-73 |

| Size ratio | % | ≥98.0 | ≥98.0 | ≥98.0 |

| Water content, as shipped | % | <1.5 | <1.5 | <1.5 |

Related Keywords

Related Keywords

You May Also Like

You May Also Like