Custom Metal Sheet Stamping and Die Metal Stamping

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Air

- Port:

- Shenzhen, Yantian, Shekou

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Air |

| Port: | Shenzhen,Yantian,Shekou |

Custom Metal Sheet Stamping and Die Metal Stamping Quote

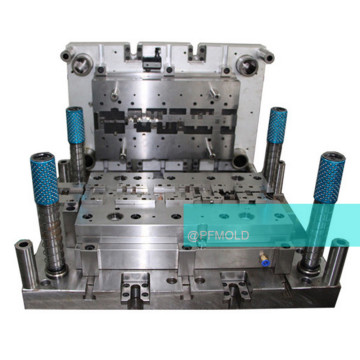

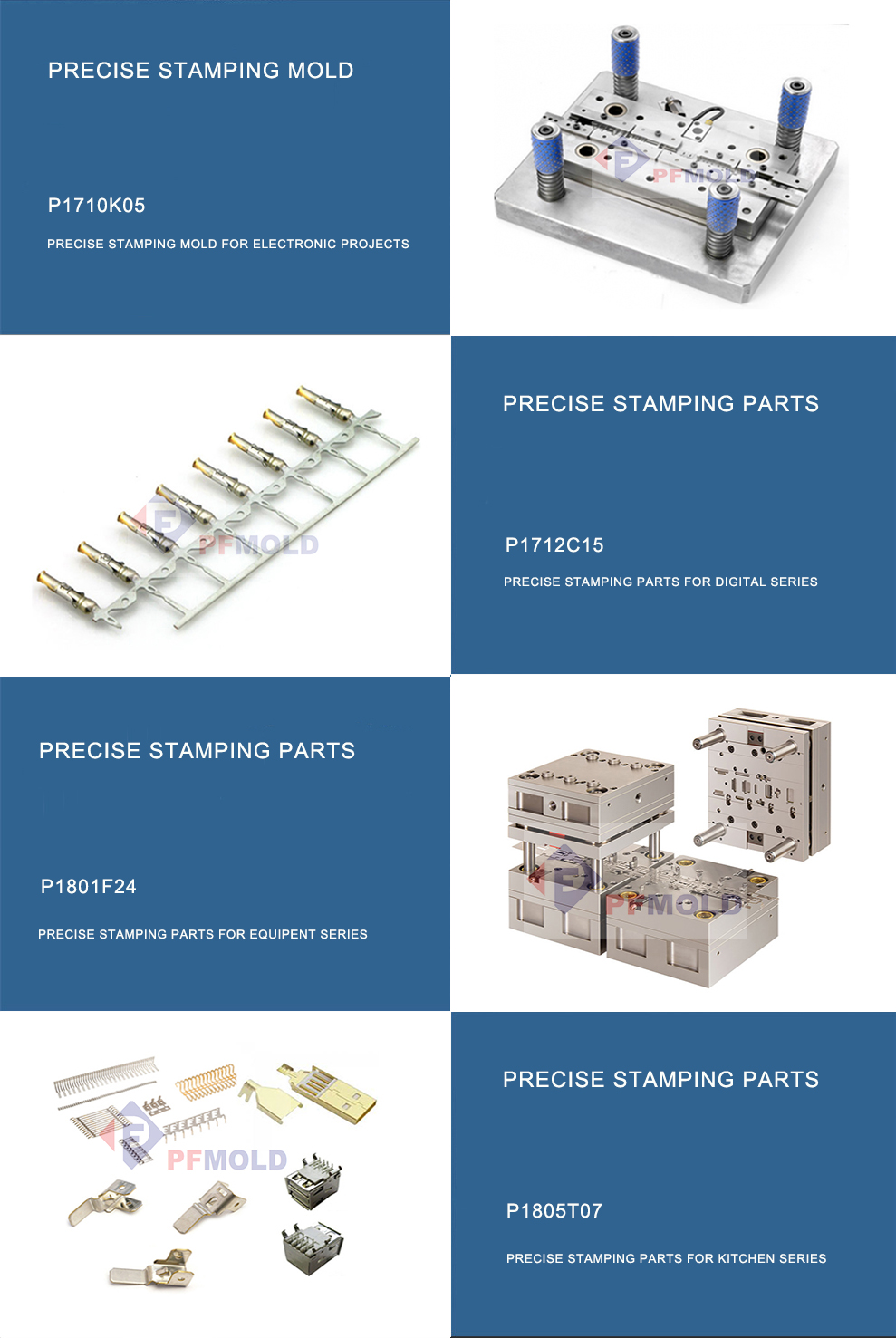

With the development of automotive technology (like automatic drive, driverless, gesture control), auto electron components will be more and more precision, functionality and performance demands gonna be higher than before. Hence electronic connector components must be more precision and professional ever than before. Our stamping pay more attention on it, keep developing and breaking new technology, from part design to mass production, aim to provide high quality parts to customer, also provide fully solution for precision stamping.Tooling For Auto Parts,Progressive Stamping Die,Metal Stamping Mould.

Tips about metal stamping:

Tips about metal stamping:

With punch press, metal stamping is the process that makes metalsheet transformed into parts with expected size and form.Stamping is cold deformation of metal. Sometimes, it is named as cold stamping or metalsheet stamping.

stamping tooling(metal or non metal) is the special tools for massive production of stampled parts, and it is essentially important.

Stamping, compare to other machining ways, it has quite a few advantages:

1. Higher efficiency and easier process, usually a punch press can stamp dozens of times per minute, some better stamping equipments can stamp hundred or even thousand of times one minute.

2. Higher Precsion and stable quality, toolings ensures precision of size and form of the products,and it can be used for quite a long time, which ensures the stable size and form of products.

3.Stamping can handle parts with more complicated form, from clock parts to longeron of trucks.

4.Stamped parts has very good strength and rigidity.

5. Metal Stamping use less materials, because there is no waste trimmings produced.

6. Enviroment friendly production process, stamping is a cold process, without heating.

Because of the above said good things, metal stamping is widely used in the industries, 80% parts in a wrest watch are stamped parts, Tv set, handy camera 90%.

But one tooling only for one product, sometime, a product needs quite a few sets of tooling, stample tooling requires precision, and technology.

There were setbacks and shortcoming for metal stamping, mainly noise. Nowdays, modern equipment has improved greatly and solving thes problems gracefully.

Products show:

About Us:

Package:

Related Keywords