Automatic Mobile Phone BGA Rework Station

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Air

- Port:

- SHENZHEN, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB |

| Certificate: | CE |

| Transportation: | Ocean,Air |

| Port: | SHENZHEN,Yantian |

Features:

1. Made of quality heating material;desoldering and solding procedures of BGA are precisely controlled;

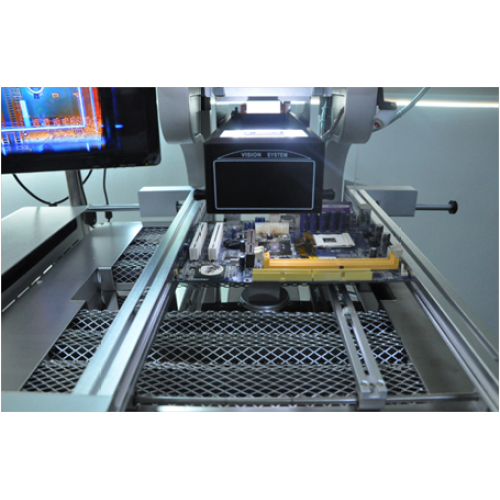

2. Movable heating head,which can be moved freely horizontally; easy to be operated;

The temperature of the upper and bottom are hot air and large botton IR heater area , three temperature heating zones and left temperature-control settings make the rework safer and more reliable .

3. The temperature of the upper and lower hot air guns can be precisely controlled according to their specific temperature, the infrared constant temperature heating zone at the lower part and the appropriate temperature-control settings make the rework safer and more reliable .

4. Embedded industrial computer,Touch screen interface,PLC control,real-time temperature curve display, be able to display temperature curves and detecting curves at the same time;

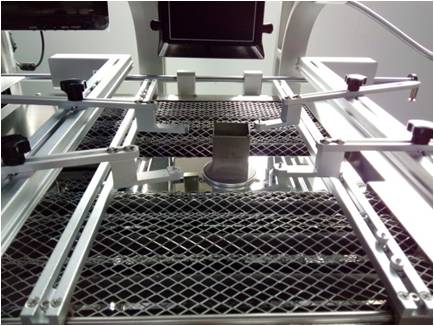

5. Powerful cross flow fans cool the bottom heating area rapidly.

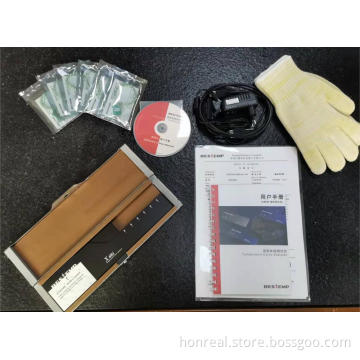

6.Equipped with different hot air nozzles,easy to replace and 360°rotation in any angle.

7. The adjustable PCB positioning support,onto which the special fixtures for allotype board could be installed, enables easy and fast positioning of the PCB board .

8. The supports for the BGA soldering supporting frame are mirco-adjustable to restrain local sinkage;

9.8 segments of temperature control,200 groups of temperature curve are stored,Curve analysis can be carried out on the touchscreen.

10.Both the upper and bottom parts are equipped with over temperature alarming and protection apparatus.

11. Buzz after solding is finished or desoldering;hand vacuum pen is adjustable for removing BGA;

12.The integrated design of machine and chassis is room-saving.could be altered to instrument-control.

13.With different alloy hot gas nozzles,easy to replace, it could be tailored as per the specific requirements.

Technical parameter:

|

PCB size |

W20*D20~W450*D400

|

|

PCB thickness |

0.5~4mm |

|

Temperature control |

K-type thermocouple,close cycle controlled

|

|

PCB locating way

|

Jig |

|

Bottom IR preheat |

Far infrared 2700w |

|

Top heater |

Hot air 600w |

|

Bottom heater |

Hot air 800w |

|

Power supply |

Single phase 220V,50/60Hz, |

|

Machine dimension |

L660*W630*H600mm |

|

Weight |

Approx. :60kg

|

Details:

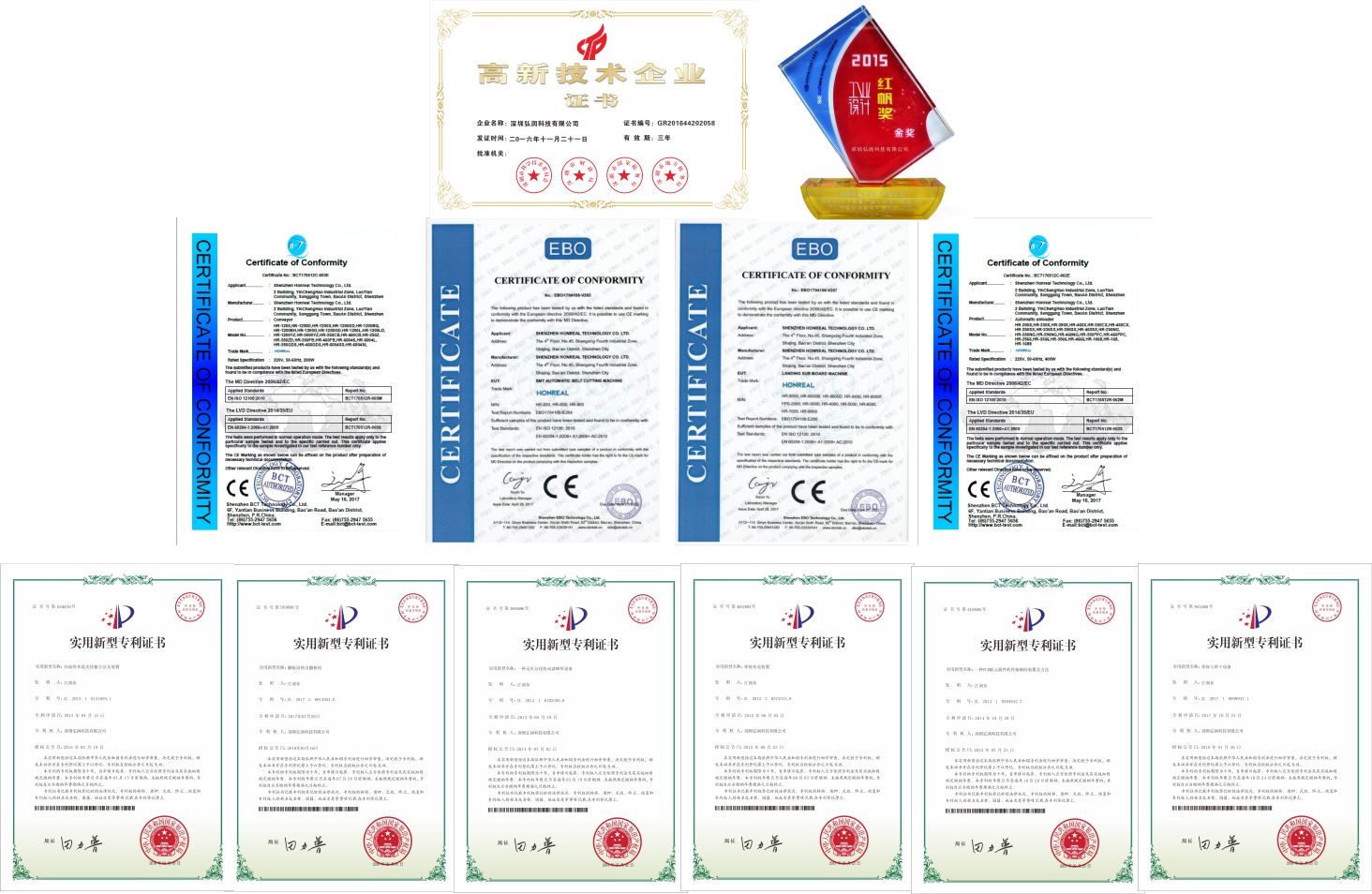

Shenzhen Honreal Technology Co.,Ltd is a national high-tech enterprise,Specializing in smt equipment research and development, production, sales. Services for the world's top 500 electronic companies.The registered capital of the company is 5 million.Since the establishment of the company, Honrealhas persisted in the development of technology as the core, quality as its survival, independent research and development, and continuous innovation. After continuous efforts, it has a number of high-tech invention patents

Certification:

If you send inquiry to us ,will be get gifts and surprises.

Related Keywords