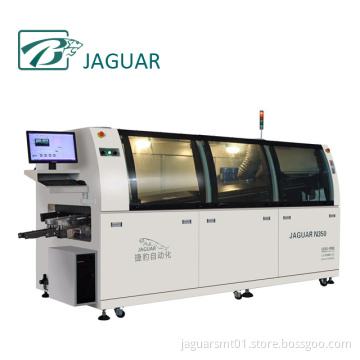

SMT high efficiency wave soldering machine, welding machine for plug components

Your message must be between 20 to 2000 characters

Contact Now1. Automatic conveying power system and auto synchronous board feeding functions.

2.Tin stove peak uses frequency conversing speed adjustment which can independently control the wave height.

3.Flux sprays system using scanning spray nozzle, Japanese nozzles and rodless pneumatic cylinders and PLC control, accurate and reliable.

4.PLC is used to control the machine, to ensure the reliability and stability of the system.

5.With Remote Infrared Ceramic heating pipe preheating device, heat radiation directly to the circuit board bottom, fast heating and stimulate the full activity of flux.

6.Special alloy transportation chain claws, non-stick tin and ensures the

7.quality of welding PCB board.

8.Tin stove adopts imported high frequency conversion motor independent control, stable performance.

9.Lead-free solder furnace with independent design, environment protection and safety, easy to clean.

Related Keywords