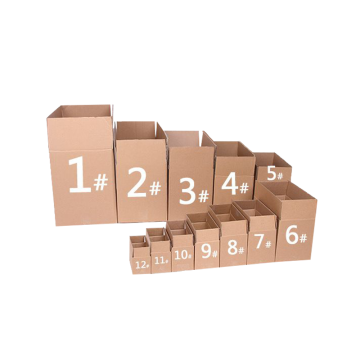

The Express Logistics Carton

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, According to customer requirements

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,Guangdong,China |

|---|---|

| Productivity: | 3,000,000 per month |

| Supply Ability: | if it is urgent,can try our best shorten the production to you. |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Transportation: | Ocean,Land,Air,According to customer requirements |

| Port: | Shenzhen |

Express logistics carton coloring processing

(1) The hard-flowing carton processing colorant is poorly diffused, which often causes a pattern to appear near the gate.

(2) The plastic or colorant has poor thermal stability. To stabilize the color tone of the part, it is necessary to strictly fix the production conditions, especially the material temperature, the amount of material and the production cycle.

(3) For crystalline plastics, try to make the cooling speed of each part of the parts consistent. For parts with large difference in wall thickness, coloring agent can be used to mask the chromatic aberration. For the parts with uniform wall thickness, the temperature and mold temperature should be fixed. .

(4) Strengthen logistics carton the shape and gate form of the processed parts of the logistics carton. The position has an influence on the filling condition of the plastic, so that some parts of the parts will have chromatic aberration and should be modified if necessary.

What to pay attention to when making logistics carton

Hardened logistics carton shaker folding resistance is an important indicator of carton quality. It is very strict in use. The flap is folded 180 degrees 5 times inward and outside, and the inner and outer papers must not be cracked. This requires controlling the quality of the raw materials, not using rough and resisting the corrugated base paper, because such corrugated base paper may cause the flap to break when folded, making the paper and cardboard uneven, which is also the main cause of the broken flap, so in production It is necessary to control the moisture content of paper and paperboard to prevent the flap from breaking.

Carton surface printing, generally using text, digital printing is more appropriate, it is easy to produce letters, numbers are not arranged neatly, different sizes, up and down skewed, irregular, non-standard, problems have not been corrected in time and layout proofreading, errata, Let the product flow into the market with quality problems, resulting in the scrapping of the entire batch of cartons. If the flatness of the cardboard is not good, the horizontal and vertical warpage will often affect the carton, which will make the carton poorly and the slotting angle will be low. This is mainly due to the poor quality of the base paper, the difference between hot and cold, wet and dry, and large shrinkage, which are caused by temperature, moisture and strength.

In addition, we also have other styles of logistics packaging, such as logistics paper box, logistics corrugated packaging cartons, logistics paper bag and so on.

Related Keywords