Plastic Mould For OEM Service

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Delivery Time:

- 40 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Shenzhen, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Shenzhen,Shenzhen |

With over 23 years experience in making Plastic Injection Mould and R&D Electronic Product Design and Software Hardware Design and Electronic PCB Design and Product Structure Industrial Design and Electronic Product for Phone & Laptop Cover Parts,manufacturing, second processing, assembly and etc. one-stop services for plastic parts.

In addition to being an OEM factory, we also have the capability of product research and development(R&D).There are several industrial, mechanical and electronics design engineers in our company. We help our customers make their ideas become final products.

Topwell was founded in 1996 in Shenzhen,China.Though nearly 20 years of growth in plastic manufacturing industry,we now have nearly 6000 sqm factory floor and more than 550 employees.we have won widely praise with favorable services and high quality products provision,becoming a large enterprise with outstanding management skill and production capacities.We have a comprehensive quality control system,which has successfully achieved ISO9001, TS16949 quality management system certification and ISO14001 Environment system certification.

Topwell appoints a project manager or engineer to each individual project.The project manger is in charge of the project from start to finish .All project manager team communicate in good English and are qualified engineers.Our professionally trained and well-matched teams will ensure you achieve high quality products and consistent service,which in turn,will help you maintain a competitive advantage over your competitors.In addition to being an OEM factory ,we also have the capability of product research and electronics design engineers in our company.We help our customers make their ideals become final products.

|

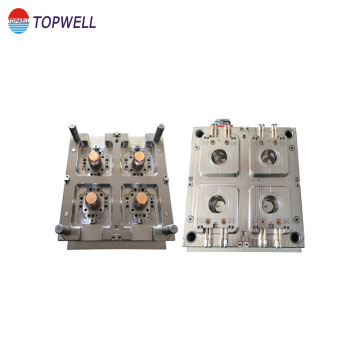

Details of Mould |

|

|

Name |

Molding For Sale |

|

Mould Material |

NAK80,S136,2316,2738,H13,718H,738H,P20,DC53 etc |

|

Product Material |

PET,PBT,PPS,PA6/PA12,LCP,PPE+PS,PPI,ABS,PC,ABS+PC,POM,HIPS. PU,PVC and PP etc |

|

Cavity No. |

Single or multi |

|

System Of Runner |

Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

|

Ejector Type |

Ejector pin,Ejector plate,Hydro-cylinder,etc |

|

Term Of Mould Production |

25days- 55days |

|

Guaranteed Number Of Cycles |

500,000-1,000,000 shots |

|

Mould Design Software |

Ug,Proe,Solidworks, AutoCAD,Moldflow,ect |

Mould Produce Process

Product Design :Customer send the product drawing to us directly or we make the product design according to the sample then send to customer for confirmation

Mould Design :We'll start to make mould design after the product drawing approval,then send the mould design to customer for confirmation

Mould Manufacture : We will start to make mould after mould design approval,the process include prepare material,rough cut,finish machining,assembly etc

Mould Test : We'll test the mould after finishing mould assembly,then we'll send samples and video of test to customer for checking

Final Process : We'll make the polishing for mould after the sample approval and make grain,nitridation or chroming if customer required

Mould Packing : We'll stard to pack the mould with wooden case after the final sample approval,then the mould will be sent to port and waiting for shipping

Related Keywords