ABS Plastic Electronic Enclosure Junction Box mold

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30~50 Days

- Transportation:

- Ocean, Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ShenZhen |

|---|---|

| Productivity: | 500K shot |

| Supply Ability: | 100 sets per month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| HS Code: | 8480719090 |

| Transportation: | Ocean,Air |

Product Description

Product Description

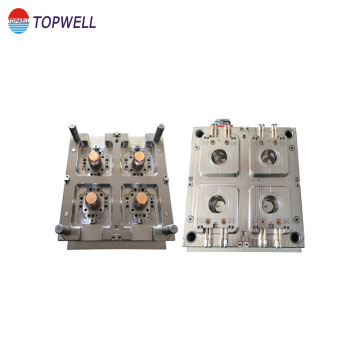

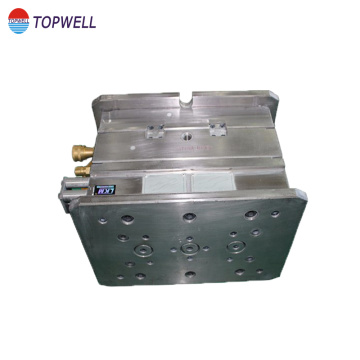

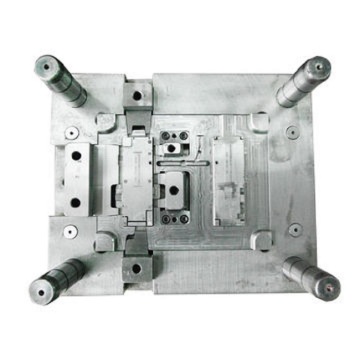

ABS Plastic Electronic Enclosure Junction Box mold

Advantages of injection plastic parts

- Competitive price

- Continuance service and support

- Diversified rich experienced skilled workers

- Custom R&D program coordination

- Application expertise

- Quality,reliability and long product life

- Mature,perfect and excellence,but simple design

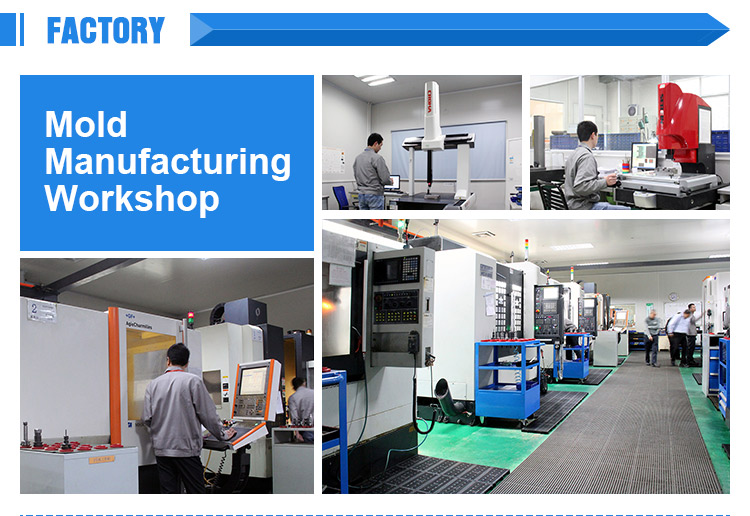

Steps of injection plastic parts

- Negotiations: Quality,material,price,payment,delivery time item and so on

- Place an order: According customer's drawing or sample

- R&D: According customer's requirements,we could design or improve 3D modeling

- Design confirmation: We send 3D drawing to customer for confirmation before we make the mould

- Mould processing: CNC EDM machine processing then assembly and trial

- Sample confirm: We will send trial sample to customers.Before shipment,If the sample isn`t satisfied by customers.We will modify mould until they are satisfied.

- Mass production: If customers need mass production of plastic products,We can offer

- Manufacturing Package and Delivery

Detail information of mold:

- Core materials: P20, 718, NAK80, S136, SKD11, 1.2738, 1.2311, 718, or customized

- Tool base: HASCO, DME or customized

- Plastic materials: PP, PE, ABS, PC, acrylic, PS, nylon + GF, TPE/TPR, silicone, PEEK, POM and PVC

- Hot-runner system: Yudo, Sino, Hasco, Incoe and LKM

- Gate: side, submarine, pinpoint, sprue, tunnel gate and can be customized

- Engraving: date stamps (year and month), logo type

- Hardness treatment: through nitrogen vacuum quenching

- Heat treated as required

- Standard mold parts: DME and Hasco

- Spare parts: assemble limited switches in mold, eye bolts, springs, nipples, O-ring, hydraulic nipples and blank logo inserts

- Design software: US, SolidWorks, Pro-E, 3D Max, AutoCAD and UG

- Process: CNC, high-speed engrave, EDM, wire cut and drill

- Minimum tool life: depends on customer's requirement, at least 500,000 shots

- Customized designs are accepted

- OEM/ODM orders are welcome

- Packing: wooden case

Related Keywords

Related Keywords