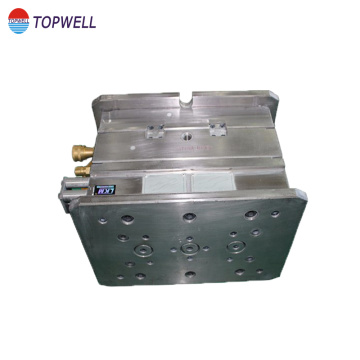

Plastic injection molding for household appliance products

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 500k |

| Supply Ability: | 100 sets mold per month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Product Description

Product Description

Mold steel: P20, NAK80, 738, 2083, S136 and H13 or specified steel by client

Mold steel brands: LKM, ASSAB or specified brand by client

Plastic resin model: ABS, PC/ABS, PC, PP or specified resin model by client

Cavity number: single cavity or multi-cavity

Mold standards: China local, DME, HASCO, Meusburger

Surface finish: polish SPI A-2/SPI D-2/MT 11010/EDM VDI texture, according to requirements

Runner system of the mold: hot runner (YUDO, mold-masters, master flow, synventive)/cold runner

Gate: pin-point gate, submarine gate, direct gate, edge gate, side gate and needle-valve

Mold life: 300,000 -1,000,000 shots, maximum up to 300,000,000 shots

Mold packing: non-fumigation wooden case

Capability: design, manufacture and exportation for precise molds, as well as plastic injection molding and providing one-stop service including silkscreen, painting, plating and assembly

Mold capability: KD makes 70-80 sets of molds per month and 40% of our molds are shipped overseas

60% of them are used in KD for mass production

Injection capability: 50-650 tons injection molding machines

Applications: optical and medical parts, auto parts, consumer electronics, smart devices, medical devices, security products, optical lens and office equipment

Payment terms:

Tool payment: 40% deposit, 30% first sample shot, 30% before mold delivery

Production payment: 100% payment after finished

Shipping terms: Ex-Work, FOB SZ, FOB HK, DDP

Mold steel brands: LKM, ASSAB or specified brand by client

Plastic resin model: ABS, PC/ABS, PC, PP or specified resin model by client

Cavity number: single cavity or multi-cavity

Mold standards: China local, DME, HASCO, Meusburger

Surface finish: polish SPI A-2/SPI D-2/MT 11010/EDM VDI texture, according to requirements

Runner system of the mold: hot runner (YUDO, mold-masters, master flow, synventive)/cold runner

Gate: pin-point gate, submarine gate, direct gate, edge gate, side gate and needle-valve

Mold life: 300,000 -1,000,000 shots, maximum up to 300,000,000 shots

Mold packing: non-fumigation wooden case

Capability: design, manufacture and exportation for precise molds, as well as plastic injection molding and providing one-stop service including silkscreen, painting, plating and assembly

Mold capability: KD makes 70-80 sets of molds per month and 40% of our molds are shipped overseas

60% of them are used in KD for mass production

Injection capability: 50-650 tons injection molding machines

Applications: optical and medical parts, auto parts, consumer electronics, smart devices, medical devices, security products, optical lens and office equipment

Payment terms:

Tool payment: 40% deposit, 30% first sample shot, 30% before mold delivery

Production payment: 100% payment after finished

Shipping terms: Ex-Work, FOB SZ, FOB HK, DDP

Related Keywords

Related Keywords