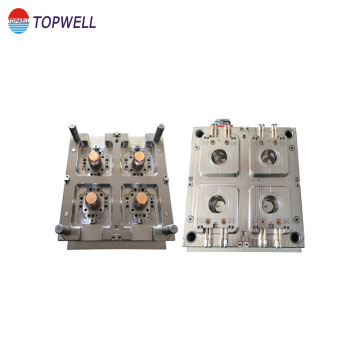

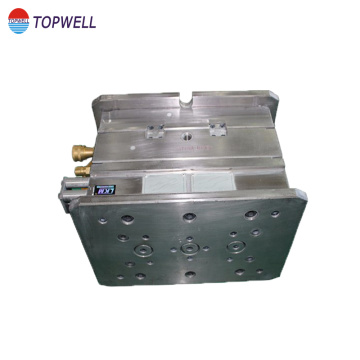

Light Sensor tooling for household injection mold

- Payment Type:

- T/T, Paypal

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 40 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 20000 Per month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen Port |

Light Sensor tooling for household injection mold, product material for PC of plastic injection mold, mold for plastic part and mold maker over than 21 years, rich experience to make for household appliance mold. Mold standard: LKM&HASCO&DME standard.

We established in 1996 in this injection mould field.We are professional OEM/ODM of plastic tooling and injection molding,secondary process and product assembly in China.Topwell has developed and manufactured a wide range of tools and plastic products for home products,Automotive, Telecommunications, OA, Medical and Electronic industry. Our main products include Air Purifier,Water purifier, Sweeping Robot, Automotive parts, GPS, Smart bluetooth Speaker, Telephones, Printers, Glucometer, Massage machine, Stereo, POS Terminal, Router and so on. Topwell is proud of being an innovative company in mold design and efficient manufacturing processes. We are committed to long term development and looking forwards to establishing a strong business partnership with your company.The management team at Topwell welcome you to here and looks forwards to working with your company for many year

Details of Mould

Name : Molding For Sale

Mould Material :NAK80,S136,2316,2738,H13,718H,738H,P20,DC53 etc

Product Material :PET,PBT,PPS,PA6/PA12,LCP,PPE+PS,PPI,ABS,PC,ABS+PC,POM,HIPS. PU,PVC and PP etc

System Of Runner :Hot runner,Cold runner,Pin-point gate,Submarine gate, etc

Ejector Type :Ejector pin,Ejector plate,Hydro-cylinder,etc

Cavity No. : Single or multi

Lead Time Of Mould Production :25days- 55days

Guaranteed Number Of Cycles : 500,000-1,000,000 shots

Mould Design Software :Ug,Proe,Solidworks, AutoCAD,Moldflow,ect

Mould Produce Process

Product Design :Customer send the product drawing to us directly or we make the product design according to the sample then send to customer for confirmation

Mould Design :We'll start to make mould design after the product drawing approval,then send the mould design to customer for confirmation

Mould Manufacture : We will start to make mould after mould design approval,the process include prepare material,rough cut,finish machining,assembly etc

Mould Test : We'll test the mould after finishing mould assembly,then we'll send samples and video of test to customer for checking

Final Process : We'll make the polishing for mould after the sample approval and make grain,nitridation or chroming if customer required

Mould Packing : We'll stard to pack the mould with wooden case after the final sample approval,then the mould will be sent to port and waiting for shipping

Related Keywords