Ultra Bright 3mm Round Top Diffused Pink LED

- Min. Order:

- 10000 Piece/Pieces

- Min. Order:

- 10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000000 pcs/week |

| Supply Ability: | 7000000000 pcs/week |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW,FCA |

| Certificate: | GB/T19001-2008/ISO9001:2008 |

| HS Code: | 8541401000 |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN |

Ultra Bright LED Diode 3mm Pink LED;

304PRD-8 are the brightest Pink LED in 3mm through-hole LED Lamps with diffused lens. If you need a diffused pink LED with high brightness, this one won't let you disappointment. This LED will show better brightness performance on voltage of 2.8-3.0V. Compare with 304PRD-5, this 304PRD-8 can handle more operation current, which is 60mA. Even 30mA can run the light up, but the more current, the more brightness. If you need more brightness, put it on 60mA, this tiny pink LED won't let you disappointment. On the other hand, we can also produce this 3mm LED pink light with clear lens, milky lens. Contact us for more detail about it~

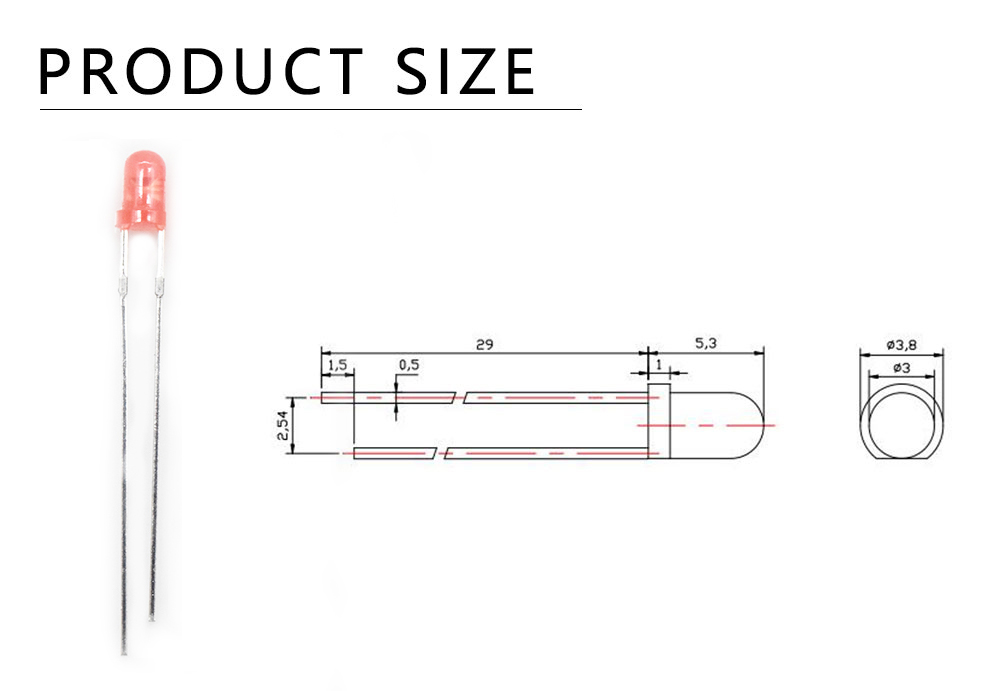

- Size: 3mm Diameter

- Pin length: 29mm

- Color: Pink LED

- Chip brand: Epistar

- Different color are available

- Different wavelength are available

- Warranty: 5 Years

- RoHS, REACH, EN62471

- Uniform light output

- Long life-solid state reliability

- Low Power consumption

-Anti UV epoxy resin package

-High temperature resistance

-Dimension Parameters -

*1. All dimensions are in millimeters ; 2. Tolerance is ± 0.20 mm unless otherwise noted.

These case are also available for Blue Through-hole LED, Red Through-hole LED, UV LED, IR LED, Amber LED, Yellow LED etc.

- Packing -

*We package this LED with 1000pcs in a bag Normally. We also can package it as your requirement.

- Production -

Storage conditions

1. avoid continued exposure to the condensing moisture environment and keep the product away from rapid transitions in ambient temperature;

2. LEDs should be stored with temperature ≤30℃ and relative humidity<60%℃;

3. Product in the original sealed package is recommended to be assembled within 72 hours of opening;

4. Product in opened package for more than a week should be baked for 6-8 hours at 85-10℃;

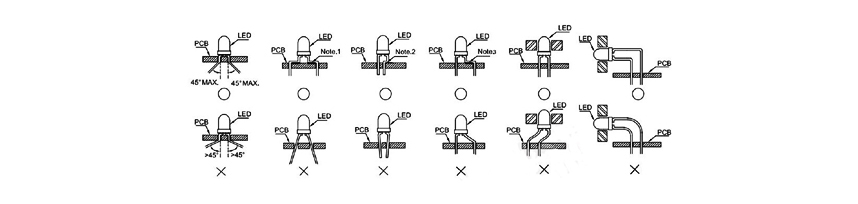

LED MOUNTING METHOD

1, The lead pitch of the LED must match the pitch of the mounting holes on the PCB during component placement;

Lead-forming may be required to insure the lead pitch matches the hole pitch;

Refer to the figure below for proper lead forming procedures;

Do not route PCB trace in the contact area between the leadframe and the PCB to prevent short-circuits;

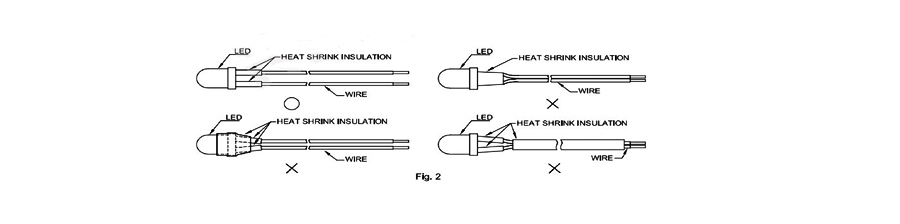

2. When soldering wires to the LED, each wire joint should be separately insulated with heat-shrink tube to prevent short-circuit contact.

Do not bundle both wires in one heat shrink tube to avoid pinching the LED leads;

Pinching stress on the led leads may damage the internal structures and cause failure;

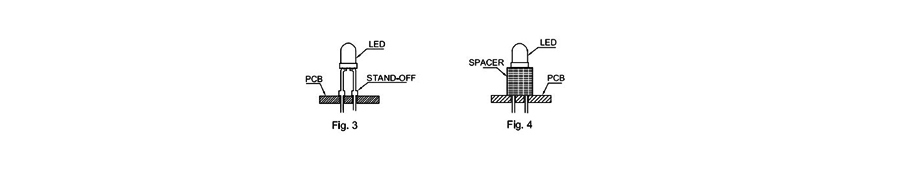

3. Use stand-offs(Fig 3)or spacers(Fig 4)to securely position the LED above the PCB;

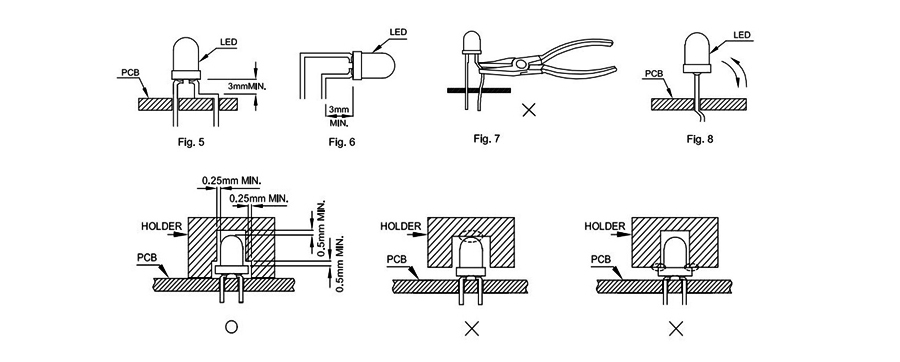

4. Maintain a minimum of 3mm clearance between the base of the LED lens and the first lead bend (Fig. 5. Fig. 6)

5.During lead forming, use tools or jigs to hold the leads securely so that the bending force will not be transmitted to the LED lens and its internal structures;

Do not perform lead forming once the component has been mounted onto the PCB;

Lead Forming Procedures

1. Lead Forming Procedures;

2. Do not bend the leads more than twice (Fig. 7);

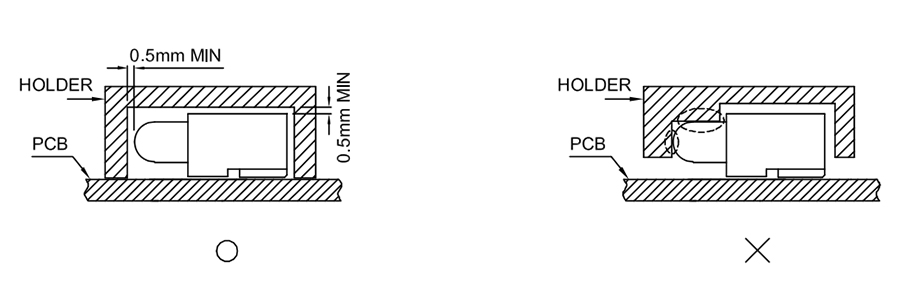

3. During soldering, component covers and holders should leave clearance to avoid placing damaging stress on the LED during soldering(Fig 8);

4. The tip of the soldering iron should never touch the lens epoxy;

5. Through-hole LEDs are incompatible with reflow soldering;

6. If the LED will undergo multiple soldering passes or face other processes where the part may be subjected to intense heat please check with Best LED for compatibility;

Related Keywords