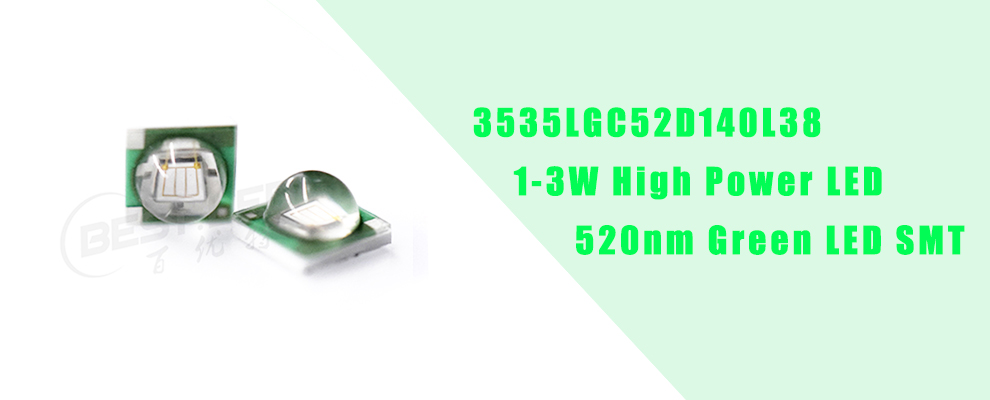

3535 SMD/SMT High Power LED Green LED

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 pcs/week |

| Supply Ability: | 10000000 pcs/week |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW,FCA |

| Certificate: | GB/T19001-2008/ISO9001:2008 |

| HS Code: | 8541401000 |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN |

High Power Green LED with 3535 SMD LED Domed Lens

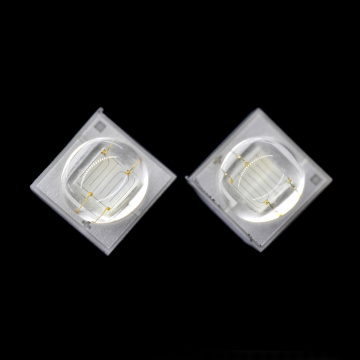

3535LGC52D140L38 is a high power Green SMD LED. Not as same as normal 3535 SMD LED, this 3535 SMT got a domed lens. Which ca increase the lighting raditaion thrugh that lens. As we said before, this is high power green LED, which it can run high operation current. Normally small green SMD LED can working at just 20mA current. With this big green LED chip inside and the high quality 3535 SMD LED case, this High power LED can work good on 700mA(suggestion operation current).

If those 2835 green SMD LED, 5050 Green SMD LED cannot meet your requried, just feel free to contact us for more detail about this.

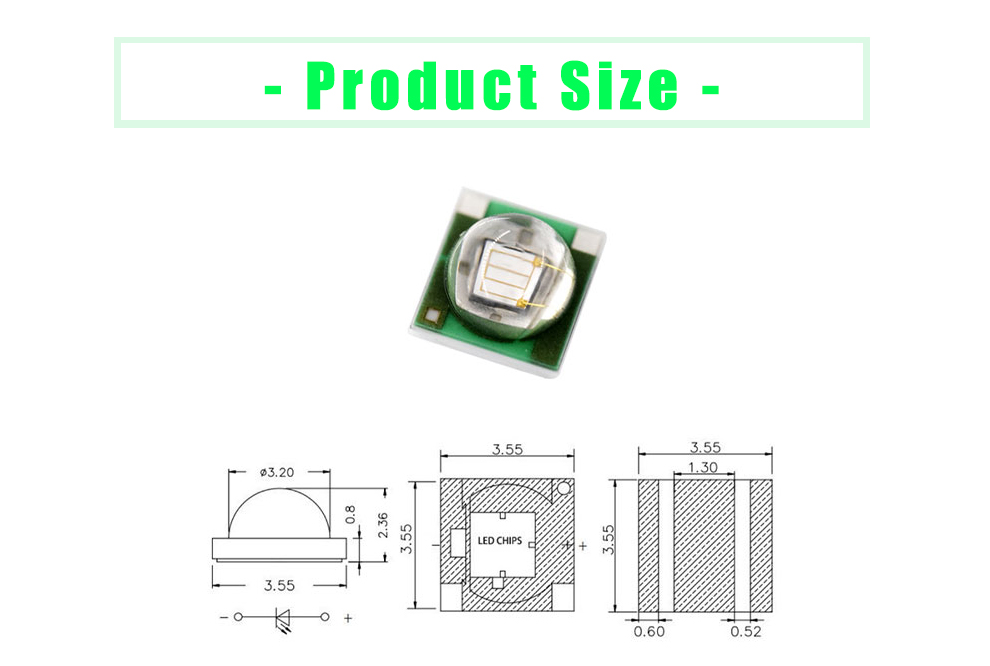

Size of 3535 Green SMD LED:

Electrical Parameters:

|

Parameter |

Symbol |

Rating |

Unit |

|

Power Dissipation |

Pd |

3000 |

mw |

|

Pulse Forward Current |

IFP |

1000 |

mA |

|

Forward voltage |

IF |

≤700 |

mA |

|

Reverse Voltage |

VR |

5 |

V |

|

Junction Temperature |

Tj |

115 |

℃ |

|

Operating Temperature |

Topr |

-40 - +80 |

℃ |

|

Storage Temperature |

Tstg |

-40 - +100 |

℃ |

|

Soldering Temperature |

Tsol |

260 |

℃ |

|

Electro-Stati-Discharge(HBM) |

ESD |

2000 |

V |

|

Service lige under normal conditions |

Time |

60000 |

H |

|

Warranty |

Time |

2 |

Years |

|

Antistatic bag |

Piece |

1000 |

Back |

*Pulse forward current confition: Duty 1% and Pulse width=10us.

*Soldering confition: Soldering confition must be completed with 3 secongds at 260℃

|

Parameter |

Symbol |

Min |

Type |

Max |

Unit |

Test Condition |

|

Forward Voltage |

VF |

3.0 3.2 3.4 |

|

3.2 3.4 3.6 |

V |

IF=700mA |

|

Luminous Flux |

IV |

100 120 140 |

|

120 140 160 |

lm |

IF=700mA |

|

Peak Wavelength |

λP |

|

518 |

|

nm |

IF=700mA |

|

Dominant Wavelength |

λD |

515 520 530 |

|

IF=700mA |

||

|

Half Width |

λ△ |

|

50 |

|

nm |

IF=700mA |

|

Viewing Half Angle |

2θ1/2 |

|

120 |

|

deg |

IF=700mA |

|

Reverse Current |

IR |

|

|

10 |

uA |

VR=5V |

*Luminous intensity is measured by ZWL600.

*λD is derived from the CIE chromaticity diagram and represents the single wavelength which defines the color of the device.

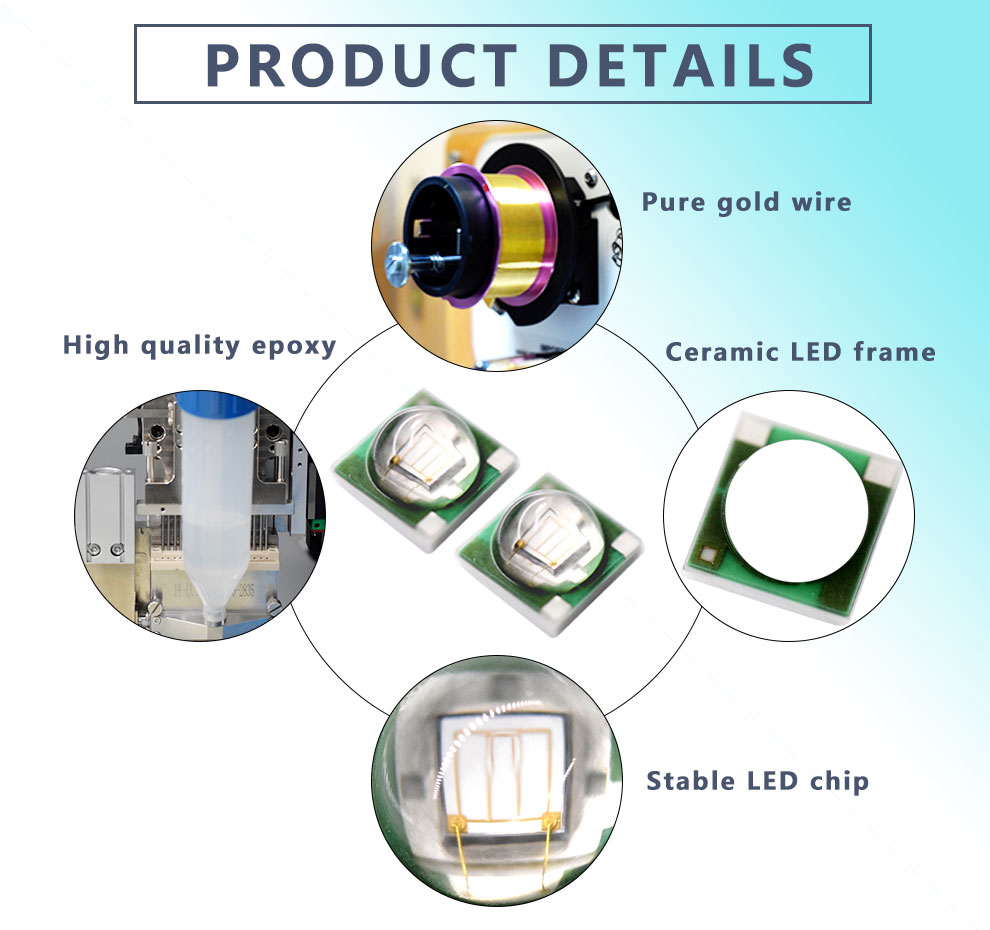

Product detail:

Are you wondering what's the material inside for connection for this LED? There are some detail as follow:

HANDLING PRECAUTIONS:

Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible Althouth its characteristiec significantly reduces thermal stress, it is more susceptible to damage by extemal mechanical force. As a result, special handling precautions need to be observed during assembly using silicone encapsulated Led products. Failure to comply might lead to damage and premature failure of the led

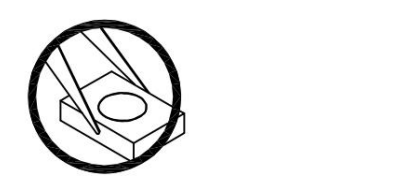

1. Handle the component along the side surfaces by using forceps or appropriate tools.

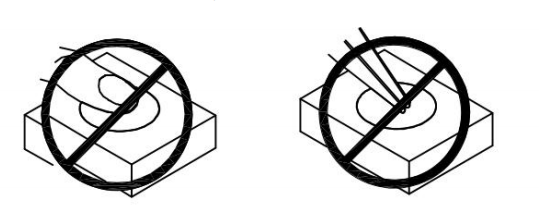

2, Do not directly touch or handle the silicone lens surface. It may damage the internal circuitry.

3, Do not stack together assembled PCBS containing exposed LEDs. Impact may scratch the silicone lens or damage the internal circuitry.

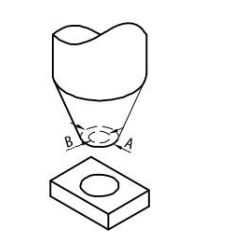

4, 4-A The inner diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air leaks;

4-B A plible material is suggested for the nozzle tip to avoid acratching or damaging the LED surface during pickup.

4-C The dimension of the component must be accurately programmed in the pick-and-place machine to insure precise pickup and avoid damage during production;

4-D As silicone encapsulation is permeable to gases, some corrosive substances such as H2S might corrode silver plationg of leadframe. Special care should be taken if an LED with silicone encapsulation is to used near such substances.

5, Please aviod continued exposure to the condensing moisture environment and keep the product away from repid transitions in ambiemt temperature.

6, Product in the original sealed package is recommended to be assembled within 24 hours of opening.

Related Keywords