Surface mount technology of circuit board

Your message must be between 20 to 2000 characters

Contact Now

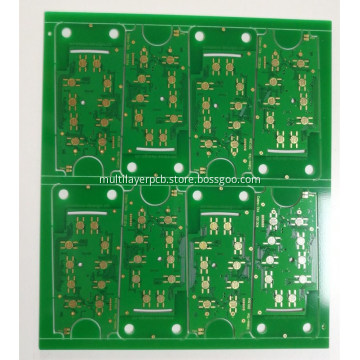

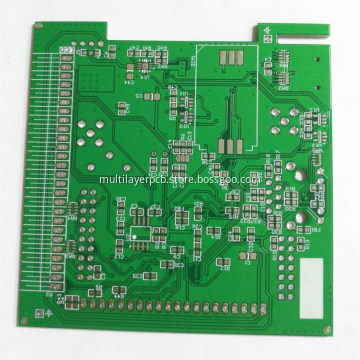

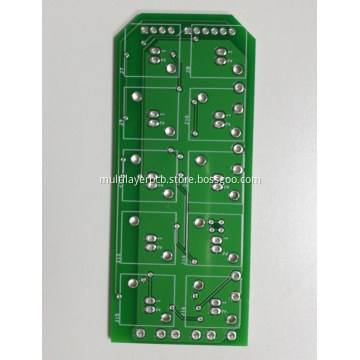

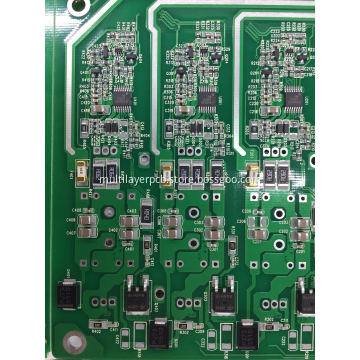

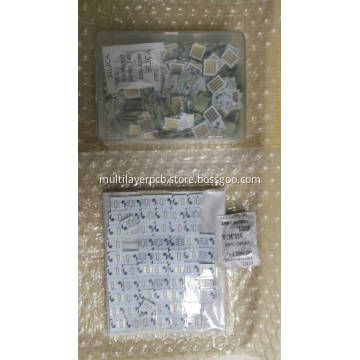

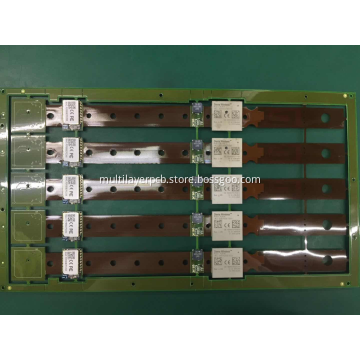

Surface mount technology of circuit board. we provide customer both pcb and pcba. this pcb is very small, unit size only 10.6*12mm. Base material FR4 S1141, TG135. Board thickness 1.2mm. White soldermask and black silkscreen. surface treatment 2U". We are required to make two sets of PCBA for different components.

The final step is to mount and solder the components. Both THT and SMT components are placed on the PCB by machines. THT components are most often soldered in an automated process called 'Wave Soldering'. This enables all components to be soldered simultaneously. Their legs are first cut near the board and slightly bent over to keep the component in place. The PCB is then moved over a wave of liquid flux, such that the bottom side strikes the flux. This removes any oxide from the metal surfaces. After heating the PCB it is similarly moved over a wave of melted solder.The solder attaches to the solder pads and component legs,and the soldering is complete.

Related Keywords