Printed circuit board surface treatment

Your message must be between 20 to 2000 characters

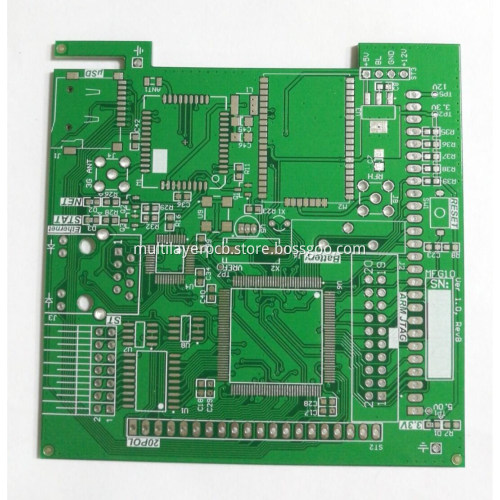

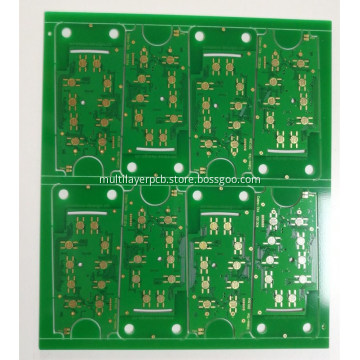

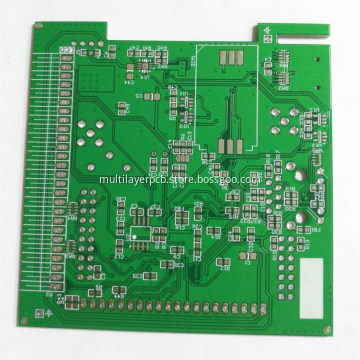

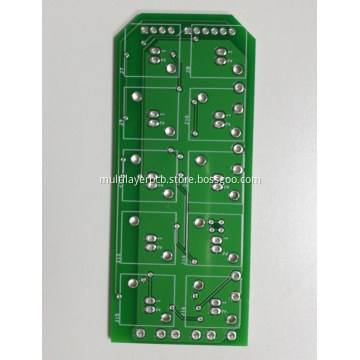

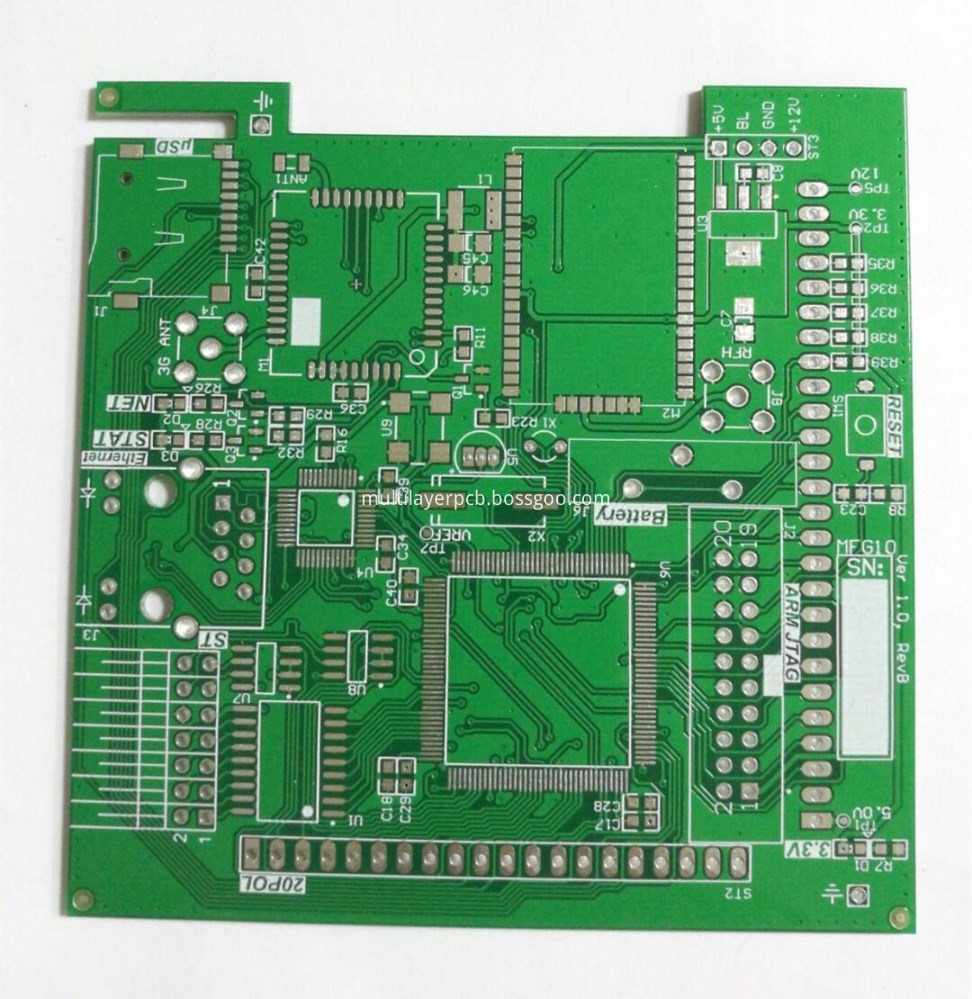

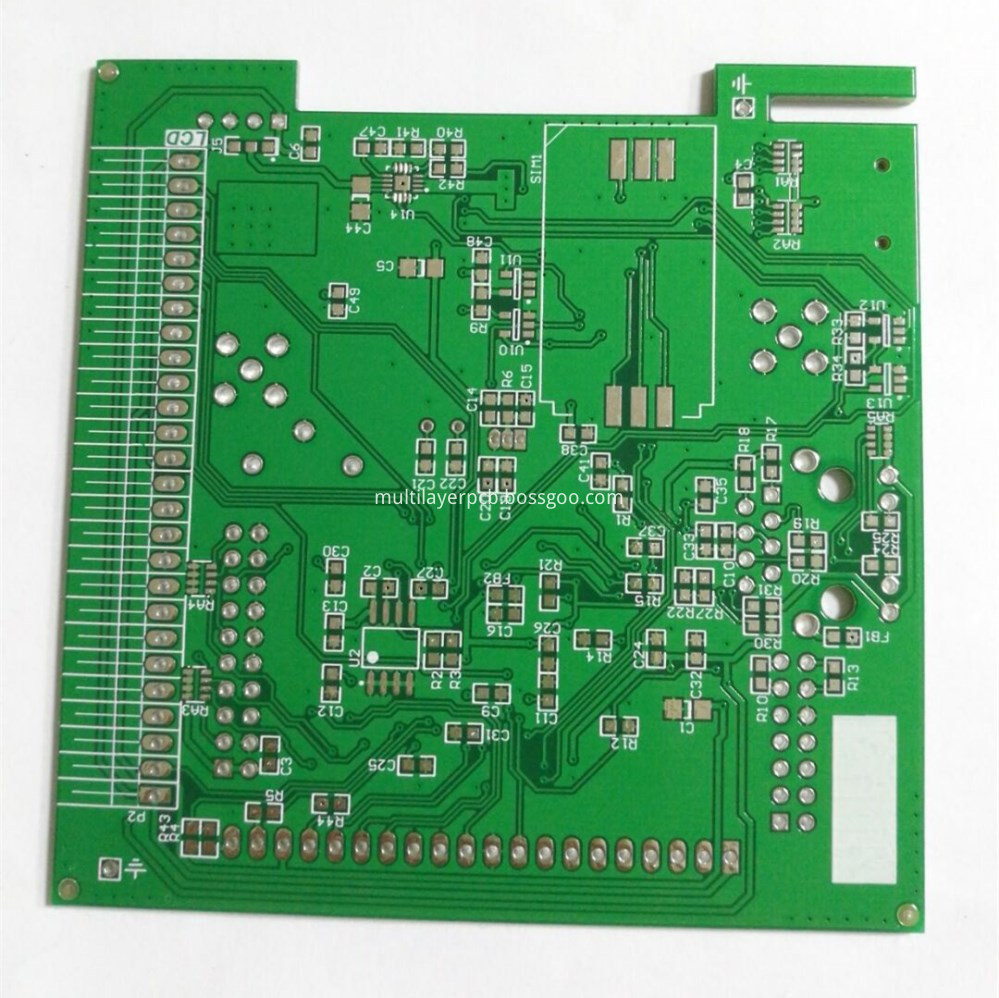

Contact Now6 Layer Hot Air Solder Level with lead pcb board, Base mertiral FR4 IT158(TG150); Inner layer 0.5oz and outer layer copper thickness 1oz finished. Min track/space 0.1/0.1mm. Green soldermask and white silkscreen.

Lead hot air solder level is made by modulating tin and lead in a certain proportion. Lead will increase the activity of tin wire in the welding process. Lead-tin wire is relatively easier to use than lead-free wire, but lead is poisonous and lead-containing. Lead is harmful to the human body; lead eutectic temperature is lower than lead-free.

According to whether it contains lead or not, HASL can be divided into two types: Hot Air Solder Level with lead and Lead-free hot Air Solder Level. If the customer requires RoHS compliance, lead-free HASL can be used.

Related Keywords