Cavity Splitter 700-3500 MHZ

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- shenzhen, guangzhou, hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 60000pcs/month |

|---|---|

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,EXW |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | shenzhen,guangzhou,hongkong |

Product Description

Product Description

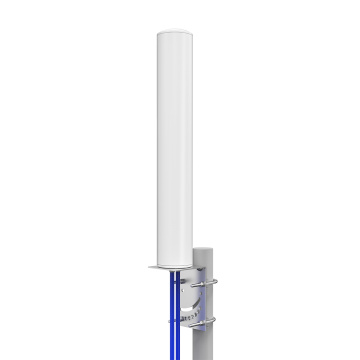

As the core equipment in the field of optics and photonics, cavity splitter can accurately distribute laser beams with high precision and stability, and is widely used in antenna systems of communication base stations. In the construction of 5G parabolic dish antenna, the reasonable use of cavity splitter can effectively improve the efficiency and quality of signal transmission. The following are the specific use steps:

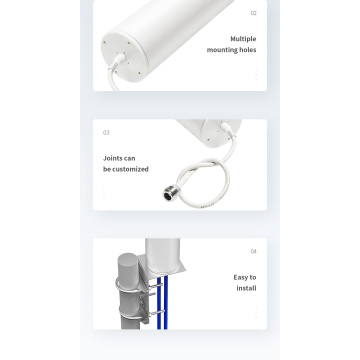

Equipment inspection and preparation: carefully check the appearance of the cavity splitter to ensure no physical damage; According to the type of equipment interface, prepare suitable optical fiber jumpers and connectors. At the same time, the 5G parabolic dish antenna is inspected comprehensively to confirm that it is in normal working condition.

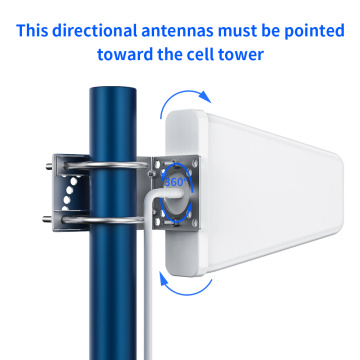

Parameter configuration and calibration: refer to the equipment manual, and set the key parameters such as shunt ratio and power distribution through the control interface or supporting software of the shunt. After the configuration is completed, professional optical power meter and spectrum analyzer are used to calibrate the splitting effect of the laser beam to ensure that the power and spectrum of each output beam meet the requirements of 5G signal transmission.

System debugging and testing: After parameter calibration, start the whole Base Stations Antennas system and observe the signal transmission. Through the background monitoring software of the base station, the strength, stability and error rate of the 5G signal are checked. If the signal is abnormal, it is necessary to check the connection of splitter and parameter setting step by step until the system runs stably.

Daily maintenance and management: clean and maintain the cavity splitter regularly, and use special cleaning tools to clean the dust and impurities on the connector end face to avoid affecting the optical signal transmission. At the same time, the equipment operation file is established to record the working state, maintenance and fault handling process of the splitter, which is convenient for subsequent maintenance and management.

It should be particularly emphasized that due to the differences in structural design, operation mode and performance parameters of cavity splitters from different manufacturers, the operation manual and safety guide provided by the equipment manufacturer must be strictly followed in actual use. In addition, operators should have professional optical knowledge and related skills to ensure the correct use of equipment and the stable operation of the system.

Related Keywords

Related Keywords