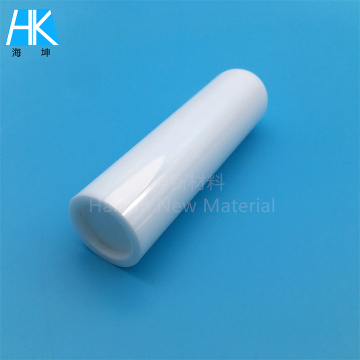

ZrO2 zirconia ceramic blind caecal tube pipe bush

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

ZrO2 zirconia ceramic blind caecal tube pipe bush

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

Zirconia ceramic tube is engineered to provide smooth and reliable performance in a variety of industrial applications.

The production of zirconia general printing paper is divided into two basic processes: pulping and papermaking. Pulp making is to dissociate plant fiber raw materials into natural pulp or bleached pulp by mechanical methods, chemical methods or a combination of the two methods. Papermaking is to combine pulp fibers suspended in water into paper that meets various requirements through various processing. Zirconia generally needs to store enough raw materials for 4 to 6 months, so that the raw materials are naturally fermented in the storage to facilitate pulping, and at the same time ensure the continuous production of paper mills. In the material preparation section, the raw materials such as reed, wheat straw and wood are cut into pieces (for the production of chemical pulp) or wood pieces (for the production of ground wood pulp), and then the small pieces of raw materials are put into the digester to add chemical liquid, and steam is used for cooking. , boil the raw material into pulp, or send the wood to the wood grinder to grind it into pulp, or it can be re-ground into pulp after a certain degree of cooking. Then, the pulp is washed with a large amount of clean water, and the coarse chips, knots, stones and sand in the pulp are removed by screening and purification.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords