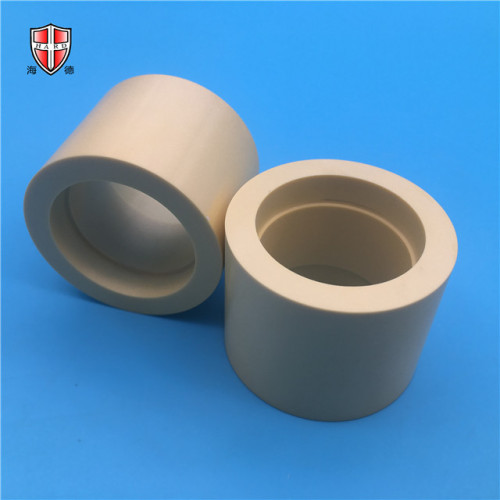

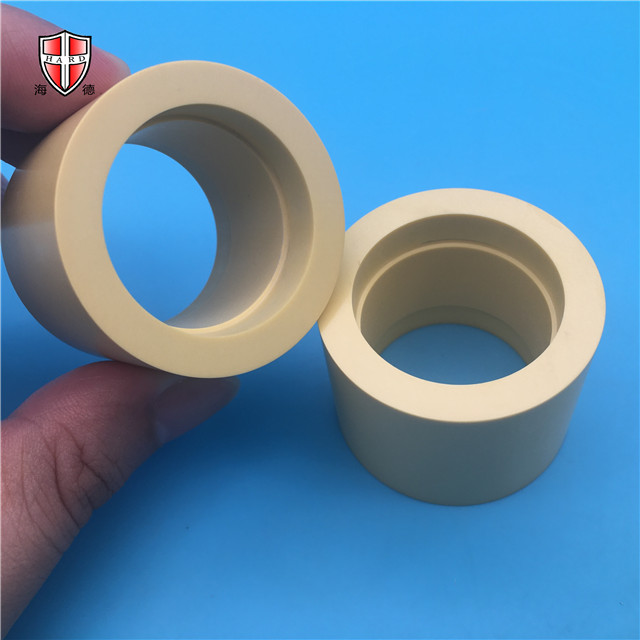

MgO magnesia stabilized yellow zirconia ceramic parts

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

MgO magnesia stabilized yellow zirconia ceramic parts

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Magnesium oxide stabilized zirconia ceramics, zirconia toughened ceramics prepared with magnesium oxide as a stabilizer. Cubic zirconia and metastable tetragonal zirconia ceramics can be prepared respectively according to the content of magnesium oxide stabilizer and the difference of preparation process. By controlling the nucleation growth of the Alumina Ceramic Bar tetragonal phase, a magnesia partially stabilized zirconia ceramic with the best flexural strength and fracture toughness can be obtained. Its application is roughly the same as that of yttria-stabilized zirconia ceramics. And more because of its unique thermal shock resistance. Widely used in metallurgy, steel and petrochemical industries. It can also be used to manufacture special ceramic cutting tools, standard measuring tools, mechanical seals, stamping dies and various wear-resistant parts in the mechanical and textile industry. Magnesium oxide ceramics belong to the cubic crystal system. Magnesium oxide ceramics have a large thermal expansion coefficient and a high vapor pressure. The melting point is 2800 °C, but it is volatile above 2300 °C; the specific volume resistance (35V/mm) at high temperature is large, with Good insulation. Magnesium oxide ceramics are typical alkaline ceramics. Magnesium oxide ceramics are generally yellow, and the operating temperature is higher than that of alumina ceramics. The operating temperature is as high as 2200°C in an oxidizing atmosphere, up to 1700°C in a reducing atmosphere, and can reach 1600-1700°C in a vacuum. In the air, Alumina Ceramic Plunger especially in humid air, magnesia ceramics are easily hydrated into industrial Mg(OH)2, and special attention should be paid to the manufacture of magnesia ceramics. High-purity magnesia ceramics have strong corrosion resistance to metals and alkaline solutions, and are used as crucibles for melting high-purity iron and alloys as well as nickel, Zirconia Ceramic Block thorium, uranium, tin, lead, zinc, copper, cobalt and their alloys; Containers for fused alumina and aluminium salts; thermocouple protection tubes made of magnesia for measuring high temperatures above 2000°C. Magnesium oxide ceramics can also be used for high temperature furnace lining.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords