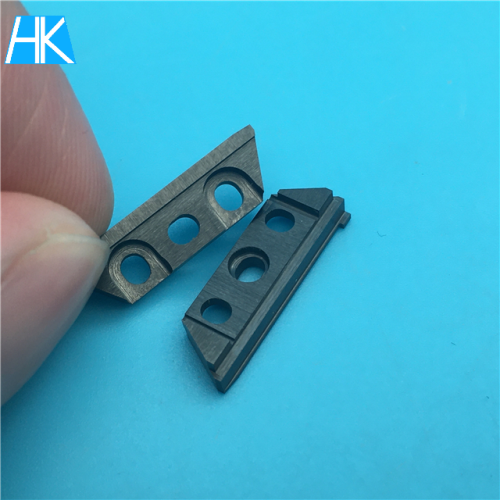

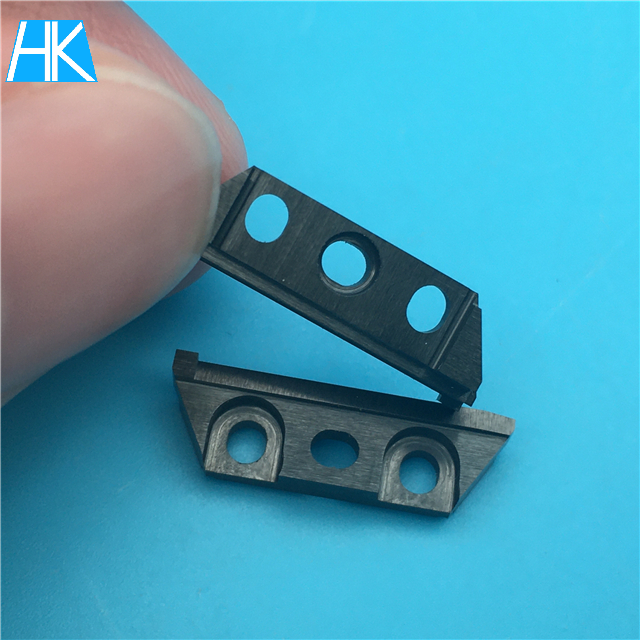

yttira precise black zirconia ceramic parts customized

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

yttira precise black zirconia ceramic parts customized

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

Although the CNC systems of various types of CNC milling machines for zirconia black ceramics are different, the functions of the various CNC systems are basically the same except for some special functions. Point position control This function can realize the hole system processing that requires high mutual position accuracy. The continuous contour control function can realize the interpolation function of straight line and circular arc and the processing of non-circular curve. Tool radius compensation function This function can be programmed according to the marked size of the Zirconia ceramic parts drawing without considering the actual radius size of the tool used, thereby reducing the complicated numerical calculation during programming. , Tool length compensation function This function can automatically compensate the length of the tool to meet the requirements of the adjustment of the tool length during processing. Proportion and mirror image processing function The proportion function can change the coordinate value of the programmed processing program according to the specified proportion to execute. Mirror processing is also called axisymmetric processing. If the shape of a part is symmetrical about the coordinate axis, then only one or two quadrants can be programmed, and the contours of the remaining quadrants can be realized by mirror processing. Rotation function

This function can execute the edited processing program by rotating it at any angle in the processing plane. Subroutine call function Some parts need to repeatedly process the same contour shape at different positions. Use this contour shape processing program as a subroutine and call it repeatedly at the required position to complete the processing of the part. Macro program function This function can use a general instruction to represent a series of instructions to achieve a certain function, and can operate on variables, making the program more flexible and convenient.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords