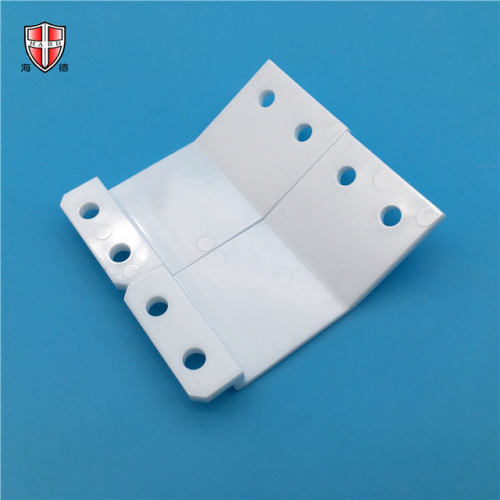

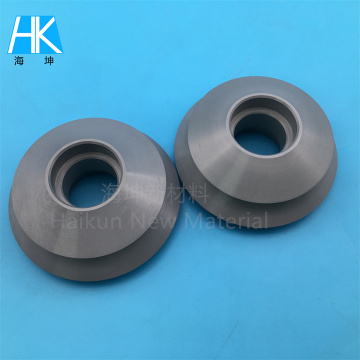

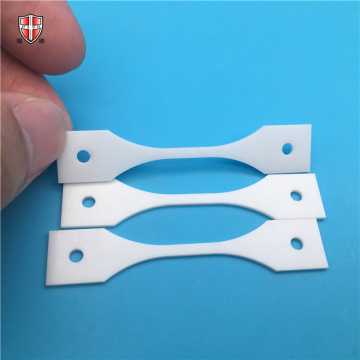

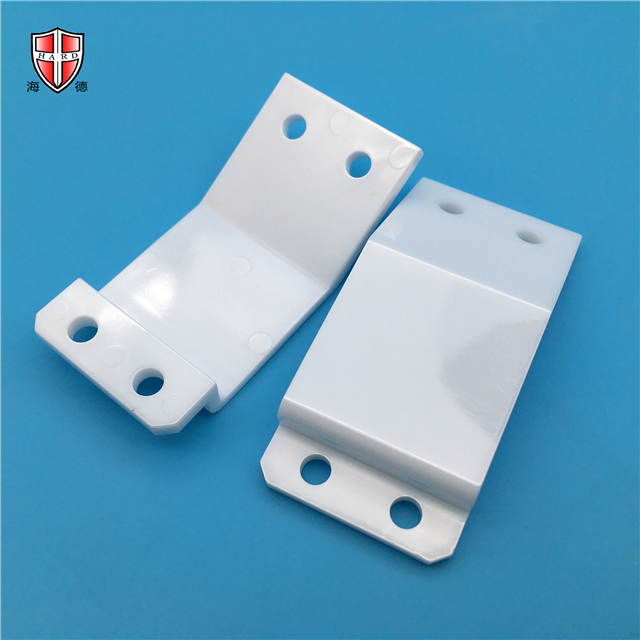

roll polishing injection molding zirconia ceramic parts

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

roll polishing injection molding zirconia ceramic parts

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

As the computing and control core of the computer system, zirconia ceramics is the final execution unit of information processing and program operation. Since the CPU came into being, great progress has been made in logical structure, operating efficiency and functional extension. The CPU appeared in the era of large-scale integrated circuits. The iterative update of processor architecture design and the continuous improvement of integrated circuit technology have prompted its continuous development and improvement. From initially dedicated to mathematical computing to widely used in general computing, from 4-bit to 8-bit, 16-bit, 32-bit processors, and finally to 64-bit processors, from the incompatibility of various manufacturers to the emergence of different instruction set architecture specifications, The CPU has been developing rapidly since its inception. The development of zirconia has a history of more than 40 years. We usually divide it into six stages. The first stage (1971-1973). This is the era of 4-bit and 8-bit low-end microprocessors, and the representative product is the Intel 4004 processor. In 1971, the 4004 microprocessor produced by Intel integrated the arithmetic unit and the controller on one chip, marking the birth of the CPU; in 1978, the appearance of the 8086 processor established the X86 instruction set architecture, and then the 8086 series processors were widely used. It is used in personal computer terminals, high-performance servers and cloud servers. The second stage (1974-1977). This is the era of 8-bit mid-to-high-end microprocessors, and the representative product is the Intel 8080. At this point, the command system is relatively complete.

Data Sheet↓

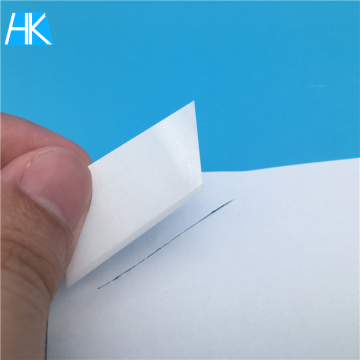

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords