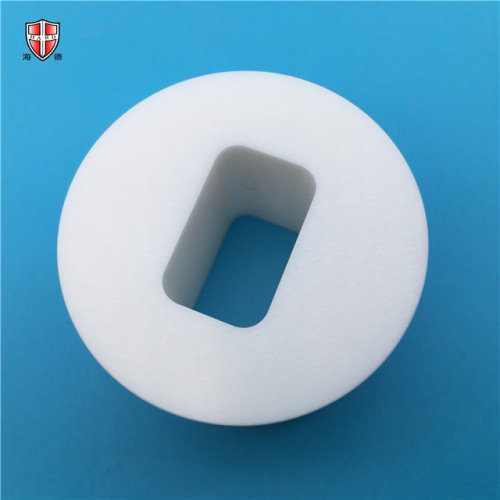

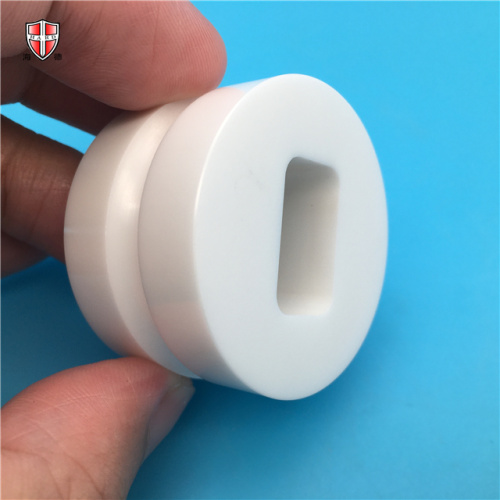

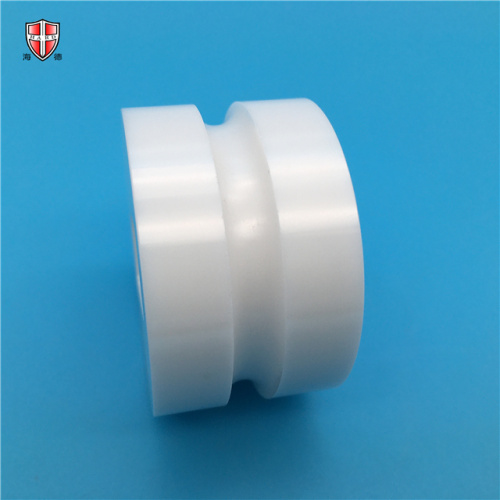

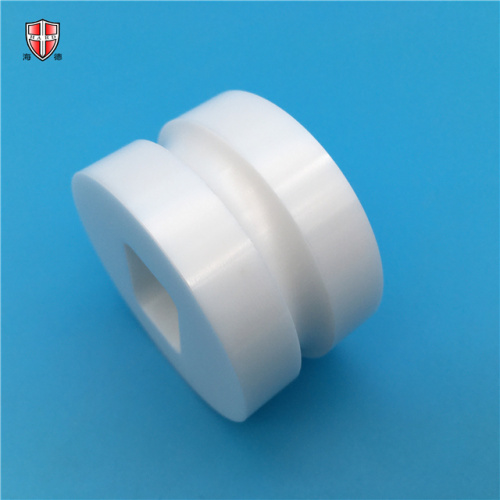

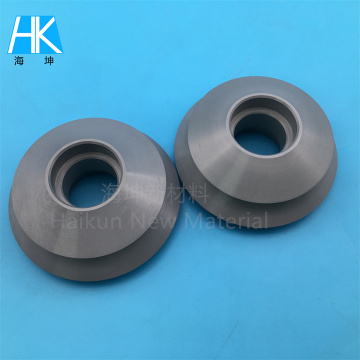

smooth zirconium oxide ceramic insulator roller caster wheel

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

smooth zirconium oxide ceramic insulator roller caster wheel

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

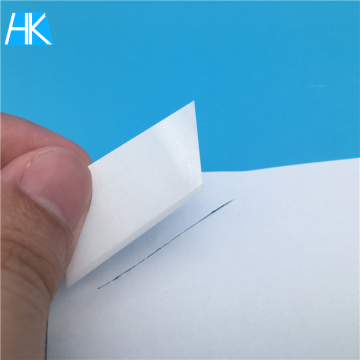

Zirconia Whiteness: The reflectance of a white or nearly white paper surface to blue light, expressed as a percentage relative to the reflectance of a standard magnesia plate. Opacity: expressed as a percentage ratio of the reflectivity of a single sample on a "totally absorbing" black liner to the reflectivity of several samples that are completely opaque. Our Zirconia Ceramic Standard Parts are specifically designed to withstand the rigors of daily operations, ensuring that your machine runs smoothly and efficiently. With our Zirconia Ceramic Parts and Bars, you can rest assured that your milling machine is equipped with the best components for long-term reliability.

Transparency: The degree to which light penetrates through the paper. It is expressed by the maximum number of layers that the sample can see the ink lines clearly. Optical performance indicators are more important for printing paper and tracing. ① Moisture: The weight of water that can be evaporated in the paper at 100~105℃ is expressed as a percentage to the weight of the paper. Ash content: expressed as a percentage of the weight of the residue after burning of the paper to the weight of the absolute dry sample of the paper. pH value: The pH value of the water extract after the paper sample is soaked in distilled water at 95-100°C for 1 hour. These chemical properties are particularly important for electrical and technical papers. Zirconia surface properties Sizing degree (water resistance): the performance of the paper surface to prevent the penetration and diffusion of ink during writing, which is very important for writing paper. Use a duckbill pen dipped in special ink to draw a line on the paper, expressed as the maximum width (mm) of the non-diffusion and non-penetrating line. Smoothness: Under a certain degree of vacuum, the time required for a certain volume of air to pass through the gap between the sample surface and the glass surface under a certain pressure, expressed in seconds.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

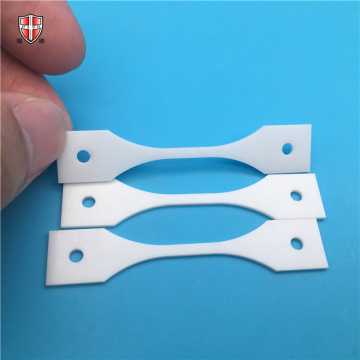

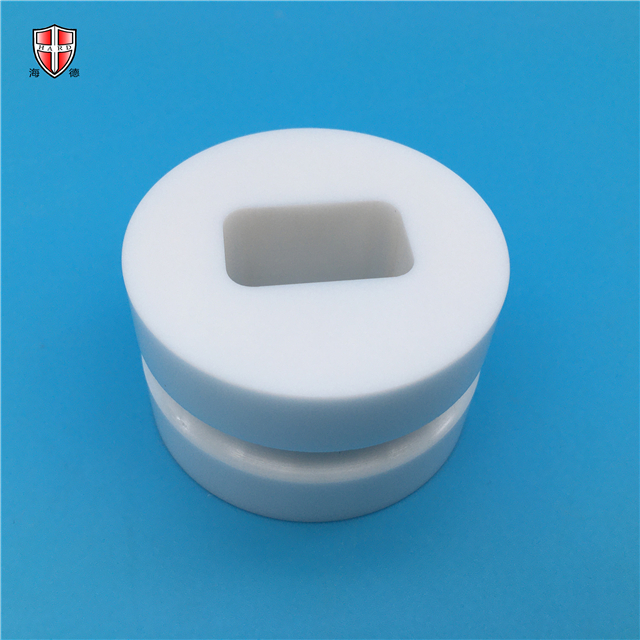

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords