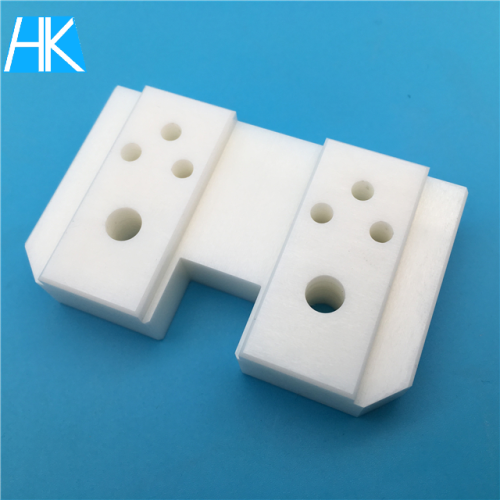

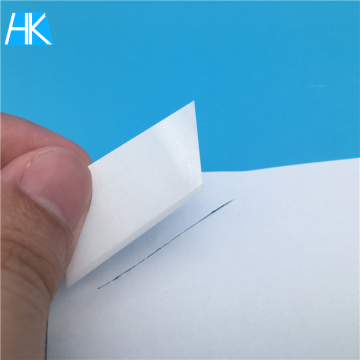

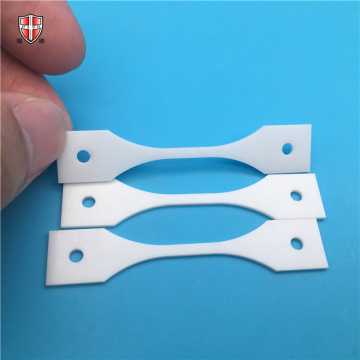

isostatic precision ZrO2 zirconia ceramic machined parts

-

$100.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1,000,000 pcs/Month |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

isostatic precision ZrO2 zirconia ceramic machined parts

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

Zirconia Ceramic Standard Parts can be processed through cold isostatic pressing (CIP) technology of zirconia and other materials. Zirconia Cold Isostatic Pressing (CIP) is a technology that usually uses rubber or plastic as the sheathing mold material at room The zirconia isostatic press is as follows: using the Pascal principle, the system is placed in a closed ultra-high claw container, and water or oil is continuously pressed into the sealed container through a booster pump to make the hydraulic pressure in the sealed container continue Increase. The high-pressure liquid (oil or water) uniformly acts on the surface of the rubber sleeve and compresses the granulated material in the rubber sleeve to form it. Because isostatic pressing is characterized by equal pressure in all directions, the formed blank has uniform density, uniform structure, and isotropy, and it can also form products with complex shapes and near-final shapes. Isostatic presses are classified according to the working medium. There are isostatic presses with a single cylinder and isolation sleeves. Their characteristics are:

1. The pressurization and depressurization of a single cylinder are carried out in the same medium, and its advantages are: the nominal cylinder diameter is the effective cylinder diameter, which can effectively use the space in the cylinder, the production volume is large, and the energy utilization rate of liquid pressurization high. The disadvantage is that if the rubber sleeve entering the cylinder is not cleaned, the ultra-high pressure water mixed with the granulated material will block and wash the valve when the pressure is relieved, requiring frequent maintenance.

2. The isostatic press with isolation sleeve is a new type of isostatic press developed on the basis of the former. The main feature is: a cylindrical rubber spacer is set in the main cylinder to separate the oil outside the sleeve from the water in the sleeve , The high-pressure oil compresses the water in the sleeve through the rubber spacer, and then presses the rubber sleeve to make the granulated material into a blank. The advantages are:

(1) The oil and water are separated by the spacer, the outer jacket is oil, the inner jacket is water, and the water mixed with the granulation material is enclosed in the water jacket, which can completely solve the pollution problem of the working medium.

(2) The outer casing oil will not cause damage to the pressure relief valve when the pressure is relieved, and it can work normally for a long time. [2]

(3) It can realize rapid pressurization at low pressure, save the forming time of granulated material, shorter than the forming time of single medium, and high efficiency.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords