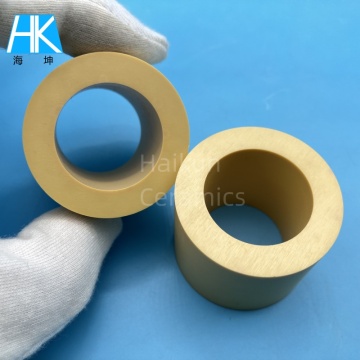

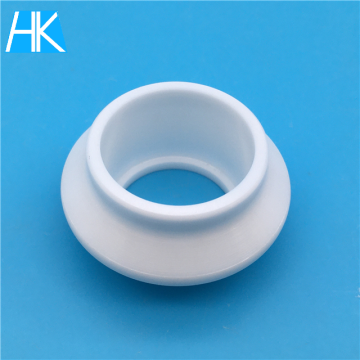

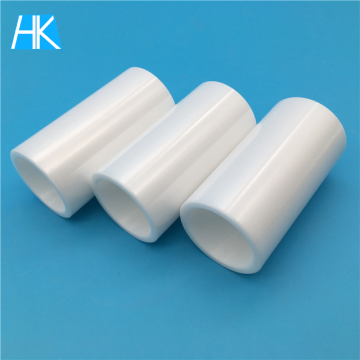

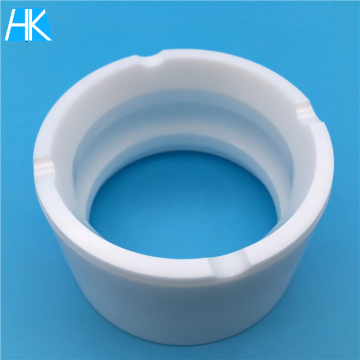

electronic custom zirconia ceramic long plug sleeve sheath

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

electronic custom zirconia ceramic long plug sleeve sheath

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramic Sleeve:

Oxidation ditch can use a combination of several methods in many cases, for example, a combination of mechanically removing oxide scale and then pickling, or a combination of salt bath and then pickling. ^In the case of the oxide layer and the diffusion layer formed at a higher temperature, a special method should be used, but the oxide layer formed when the temperature is heated to 600X: most of the oxide layer formed can be dissolved away by general pickling . Titanium alloy has the advantages of light weight, high specific strength, and good corrosion resistance, so it is widely used in the automobile industry. The most used titanium alloy is in automobile engine systems. There are many advantages to using titanium alloys to make engine parts.

The low density of zirconia can reduce the inertial mass of moving parts. At the same time, the titanium valve spring can increase free vibration, reduce the vibration of the car body, and increase the engine speed and output power.

Reduce the inertial mass of the moving parts, thereby reducing the friction and improving the fuel efficiency of the engine. Choosing titanium alloy can reduce the load stress of related parts and reduce the size of the parts, thereby reducing the quality of the engine and the entire vehicle. The reduction of the inertial mass of the parts reduces the vibration and noise and improves the performance of the engine. The application of titanium alloy to other parts can improve the comfort of personnel and the beauty of the car. In the application of the automobile industry, titanium alloy has played an inestimable role in energy saving and consumption reduction.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords