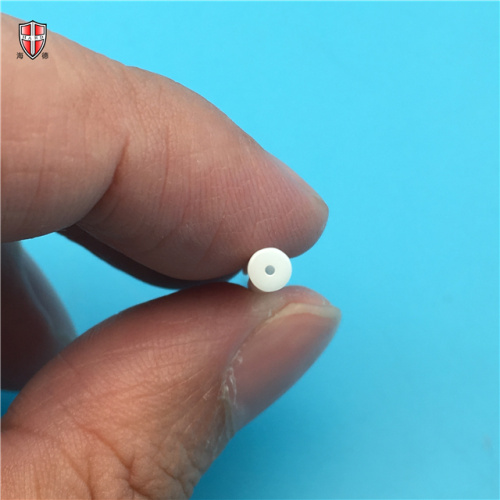

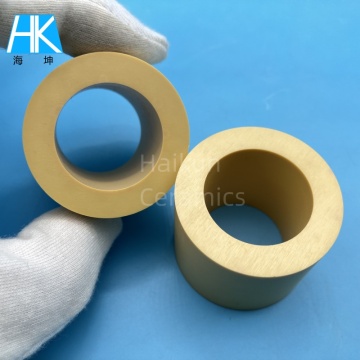

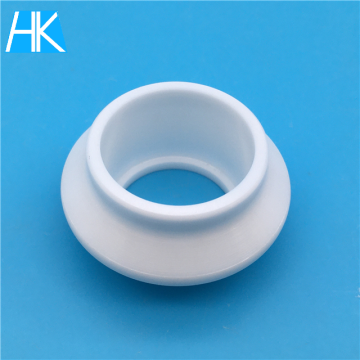

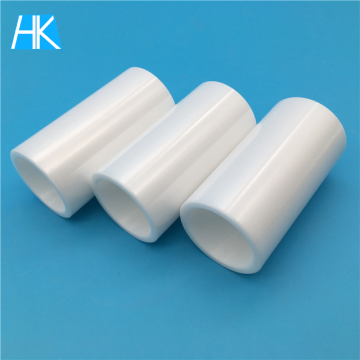

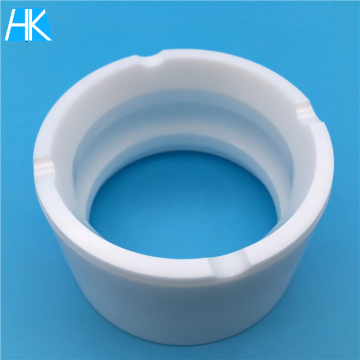

optical nuclear reactor ceramic insulating tube ferrule

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

optical nuclear reactor ceramic insulating tube ferrule

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Brass is a copper-zinc alloy, with a bright golden yellow luster on the surface, high corrosion resistance in the atmosphere, fresh water and sea water, good strength, wear resistance, heat resistance, electrical conductivity, thermal conductivity , Has high plasticity, cold and hot pressure processing performance is good, can be welded, brazed and cold cutting, heat treatment can be strengthened.

There are 11 varieties of ordinary brass, the main purpose: H59, H62, H63 aluminum alloy quenching furnace agent, H65 brass is used to manufacture hardware daily necessities, screws, nuts, pins, anchors, cushion rolls, springs, screens, Radiator, various deep extension force parts, welding parts, hot punching and hot rolling parts, etc .; H68, H68A, H70 brass are used to manufacture complex cold drawn parts and deep drawn parts, such as radiator shell, duct, bellows , Bullet casings, detonators, etc .; H80, H85 brass are used to make paper nets, thin-walled tubes, and house building supplies; H90, H96 brass are used to manufacture conduits, condensation tubes, radiator tubes, automobile water tanks, drain pipes, conductive Parts, medals, artworks, etc. Brass plays an increasingly important role in the rapidly developing machinery manufacturing industry. Selected representative H59, H62, H68, H96 four kinds of brass for analysis, test and research, and the H box-type resistance furnace price of 62 brass for cryogenic treatment strengthening test, and achieved practical results.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords