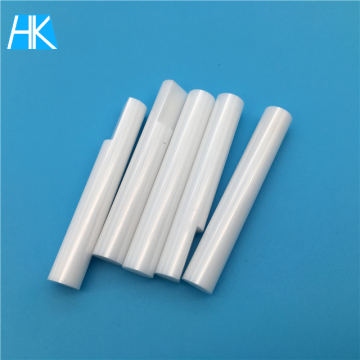

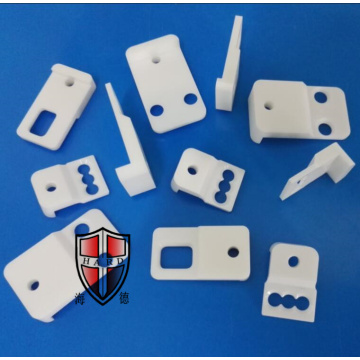

custom made polish zirconia ceramic piston shaft

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

custom made polish zirconia ceramic piston shaft

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconia ceramics use oxygen or peroxide as initiator to polymerize ethylene into low density polyethylene. Ethylene enters the reactor after two-stage compression, and is polymerized into polyethylene under the pressure of 100-300 MPa, temperature of 200-300°C and the action of initiator. The reactants are separated under reduced pressure, so that unreacted ethylene is recycled and melted. After adding plastic additives, the polyethylene is extruded and pelletized. The polymerization reactor used for zirconia has two types: tubular reactor (tube length up to 2000 m) and tank reactor. The single-pass conversion rate of the tubular process is 20% to 34%, and the single-line annual production capacity is 100 kt. The single-pass conversion rate of the kettle-type process is 20%-25%, and the single-line annual production capacity is 180 kt. Zirconia is divided into slurry method, solution method and gas phase method. Except for solution method, the polymerization pressure is below 2 MPa. The general steps include catalyst preparation, ethylene polymerization, polymer separation and granulation. ① Slurry method: The resulting polyethylene is insoluble in solvents and appears slurry. The slurry method has mild polymerization conditions and is easy to operate. Alkyl aluminum is commonly used as activator, hydrogen is used as molecular weight regulator, and tank reactors are mostly used. The polymer slurry from the polymerization tank is passed through the flash tank and the gas-liquid separator to the powder dryer, and then to granulation. The production process also includes steps such as solvent recovery and solvent refining. Different polymerizers can be combined in series or in parallel to obtain products with different molecular weight distributions.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords