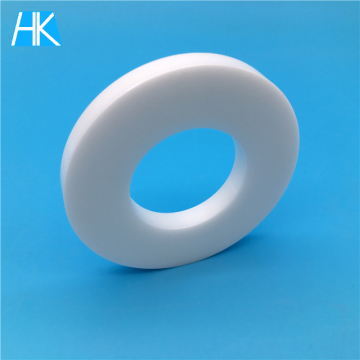

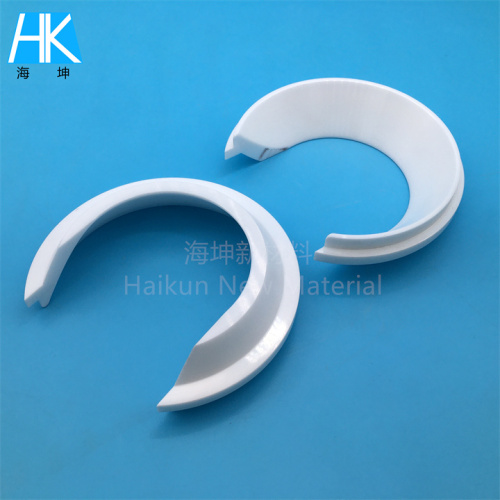

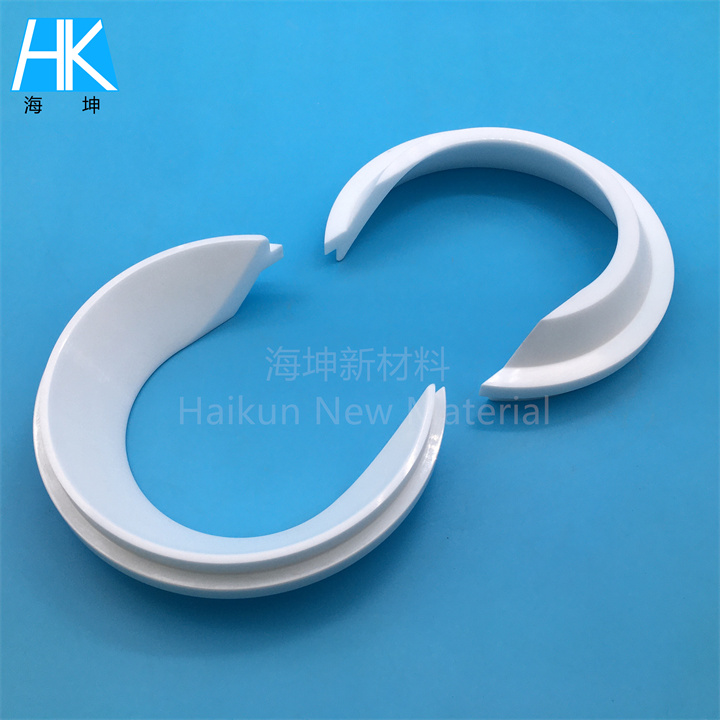

Abrasion Resistance Zirconia ceramic ring insulator part

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Guangzhou, Shenzhen, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,Express Delivery,EXW,CPT |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Guangzhou,Shenzhen,Dongguan |

Abrasion Resistance Zirconia Ceramic Spacer Ring Part

A Zirconia Ceramic Spacer Ring for the industry is a specialized component made from zirconia (ZrO2), a high-performance ceramic material known for its excellent mechanical properties, including high strength, wear resistance, and thermal stability. These rings are used in various industrial applications where they can serve several functions:

1. Sealing and Insulation

- Sealing: They can be used to seal gaps between moving parts or to prevent fluid leakage in machinery.

- Insulation: Their low thermal conductivity makes them useful in applications requiring insulation against heat.

2. Support and Load-Bearing

- Supporting Components: In precision machinery, spacer rings may provide support for other components, ensuring precise positioning and alignment.

- Load Distribution: They can evenly distribute loads across surfaces, reducing stress on critical components.

3. Wear Resistance

- Zirconia ceramic is highly resistant to wear, making it ideal for parts that experience significant friction or abrasion.

4. Corrosion Resistance

- Due to its chemical inertness, zirconia is resistant to corrosion by many chemicals, making it suitable for use in harsh environments.

5. High Temperature Applications

- Zirconia can withstand high temperatures without losing its structural integrity, making it valuable in high-temperature industrial processes.

6. Precision and Accuracy

- The material's consistency and precision in manufacturing allow for tight tolerances, which is crucial in applications requiring high accuracy.

Selection and Application Considerations:

When selecting a zirconia ceramic spacer ring, factors such as the operating temperature, required mechanical strength, chemical compatibility, and environmental conditions must be considered. Additionally, the size, shape, and surface finish of the ring should match the application's specific requirements.

Manufacturing Process:

Zirconia ceramic spacer rings are typically manufactured using advanced techniques such as powder injection molding (PIM), hot isostatic pressing (HIP), or sintering, followed by machining to achieve the desired dimensions and surface finish.

Conclusion:

Zirconia ceramic spacer rings offer a combination of high performance and durability, making them an essential component in a variety of industrial applications where reliability, efficiency, and longevity are paramount.

Related Keywords