glass fibre silver plating gel zirconia pilot pin

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

glass fibre silver plating gel zirconia pilot pin

Reputation depends on quality, quality comes from Hard!

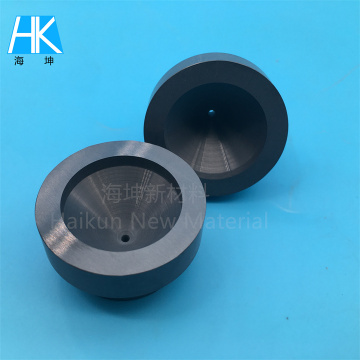

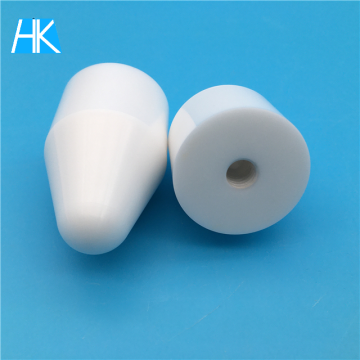

Zirconia Ceramic Pin:

The heat treatment process of zirconia ceramics can be summarized as:

Stress relief annealing: the purpose is to eliminate or reduce the residual stress generated during processing. Prevent chemical attack and reduce deformation in some corrosive environments. Complete annealing: The purpose is to obtain good toughness, improve processing performance, facilitate reprocessing and increase the stability of size and organization. Solution treatment and aging: The purpose is to improve its strength, α titanium alloy and stable β titanium alloy cannot be strengthened heat treatment, only annealing in production. α+β titanium alloy and metastable β titanium alloy containing a small amount of α phase can further strengthen the alloy through solution treatment and aging. In addition, in order to meet the special requirements of the workpiece, the industry also adopts metal heat treatment processes such as double annealing, isothermal annealing, β heat treatment, and thermomechanical heat treatment. When the hardness of titanium alloy is greater than HB350, cutting is particularly difficult, and when the hardness is less than HB300, it is prone to sticking and cutting. But the hardness of titanium alloy is only one aspect that is difficult to cut. The key lies in the influence of the combination of chemical, physical and mechanical properties of titanium alloy on its machinability. Zirconia ceramics have the following cutting characteristics: Small deformation coefficient: This is a significant feature of titanium alloy cutting processing, and the deformation coefficient is less than or close to 1. The sliding friction distance of chips on the rake face is greatly increased, which accelerates tool wear. High cutting temperature: Because the thermal conductivity of titanium alloy is very small (only equivalent to 1/5 to 1/7 of 45 steel), the contact length between the chip and the rake face is extremely short, and the heat generated during cutting is not easy to be transferred and concentrated In a small area near the cutting zone and the cutting edge, the cutting temperature is very high. Under the same cutting conditions, the cutting temperature can be more than twice as high as when cutting No. 45 steel. The cutting force per unit area is large: the main cutting force is about 20% less than when cutting steel. Because the contact length between the chip and the rake face is extremely short, the cutting force per unit contact area is greatly increased, which is easy to cause chipping. At the same time, due to the small modulus of elasticity of titanium alloy, it is prone to bending deformation under the action of radial force during processing, causing vibration, increasing tool wear and affecting the accuracy of parts. Therefore, the process system is required to have good rigidity.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords