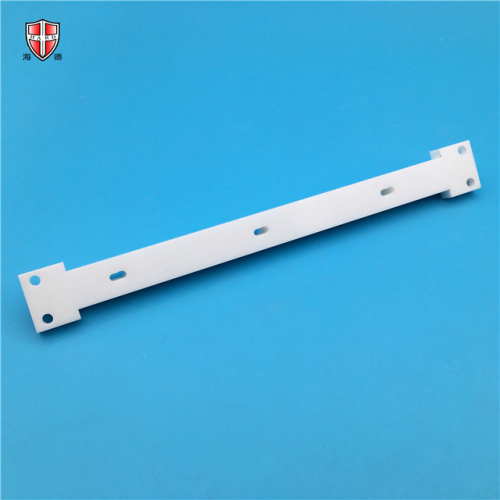

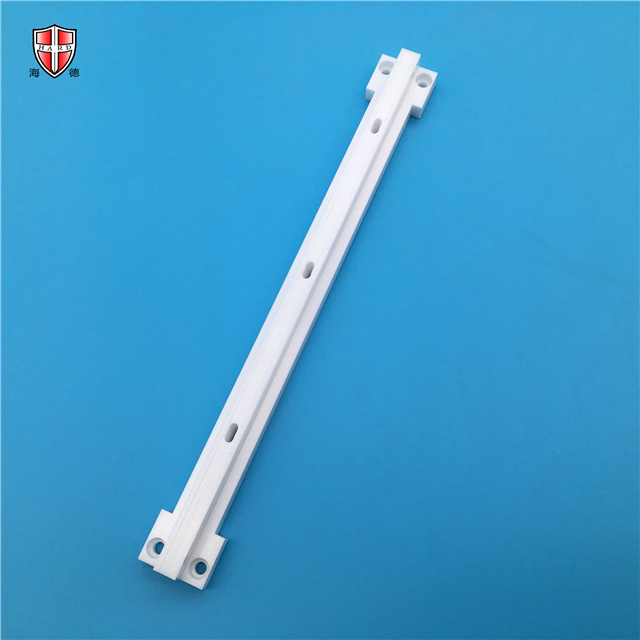

low heat conductivity milling zirconia ceramic bar stick

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

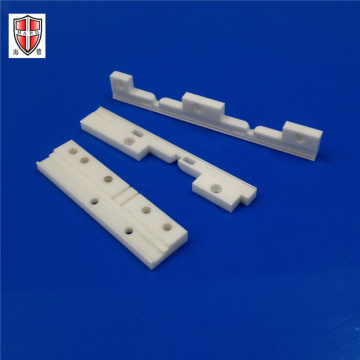

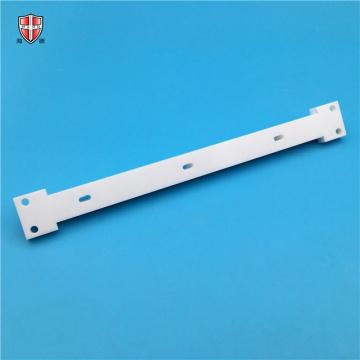

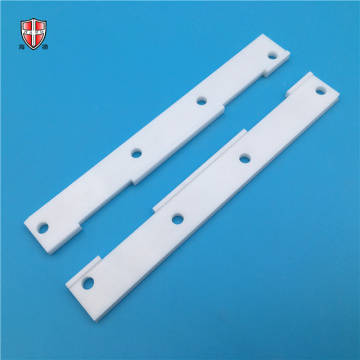

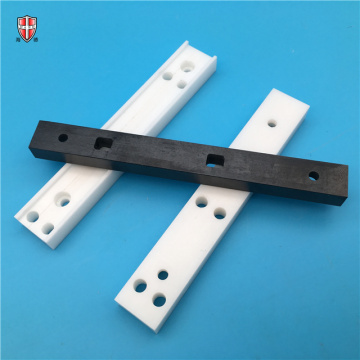

low heat conductivity milling zirconia ceramic bar stick

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

The zirconia is then bleached to the required brightness with a bleaching agent according to the requirements of the paper type, and then beaten by beating equipment. Then, various auxiliary materials such as fillers, sizing materials, sizing agents, etc. to improve the performance of paper are added to the pulp, and purified and screened again. Take, and slit and rewind or cut to produce roll paper and flat paper. If the production is to produce coated printing paper, it needs to be dried in the middle or produced into a roll paper and then processed by coating. In addition to the above basic processes, it also includes some auxiliary processes, such as the preparation of cooking liquid, the preparation of bleaching liquid, the cooking of rubber materials, and the recovery of chemicals and heat energy in cooking waste liquid and waste gas. Due to the continuous breakthrough of papermaking technology, a toilet paper manufacturer in the United States cited such a new papermaking technology; the raw materials for making toilet paper are used writing paper and waste printing paper, which are first mashed into pulp. The pulp is then filtered, gradually bonded and pumped, and finally cut and packaged. After these processes are completed, the produced toilet paper can be used again. This technology can not only use waste and save resources, but also the process of making paper is simpler than traditional processes.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords